La distillation en colonne par lots est un processus intéressant et joue un rôle majeur dans la pureté de nombreux produits courants que nous utilisons. Tout ce que nous consommons, de l'eau potable aux parfums et bien d'autres encore, est raffiné grâce à la procédure de distillation en colonne par lots. Dans l'exploration détaillée qui suit, nous expliquerons ce qu'est la distillation en colonne par lots en ce qui concerne son fonctionnement et ses avantages, ainsi que certaines des applications typiques réalisées à l'aide de cette technique dans des secteurs comme celui des pharmaceutiques...

La distillation par colonne par lots est un procédé permettant de séparer partiellement différents liquides en fonction de leurs points d'ébullition. Il est largement utilisé dans les industries pharmaceutique et pétrochimique, ainsi que dans de nombreuses entreprises agroalimentaires lors du dessalement des flux liquides. Un passage par la colonne de distillation par lots consiste à diviser le processus principal en lots ou étapes, ce qui permet de purifier tous types de liquides facilement avec une seule colonne.

Plus important encore, la qualité de ses produits est l'un des nombreux avantages notables de la distillation par colonne par lots. Procédé de séparation des liquides bouillants : chauffer le mélange de deux liquides à leur point d'ébullition et les recueillir. C'est un procédé qui fait bouillir un liquide sans affecter les IMPURETÉS de l'autre -> pur et exempt de contamination. De plus, la distillation par colonne par lots est un moyen coûteux efficace pour produire de l'alcool en petites quantités.

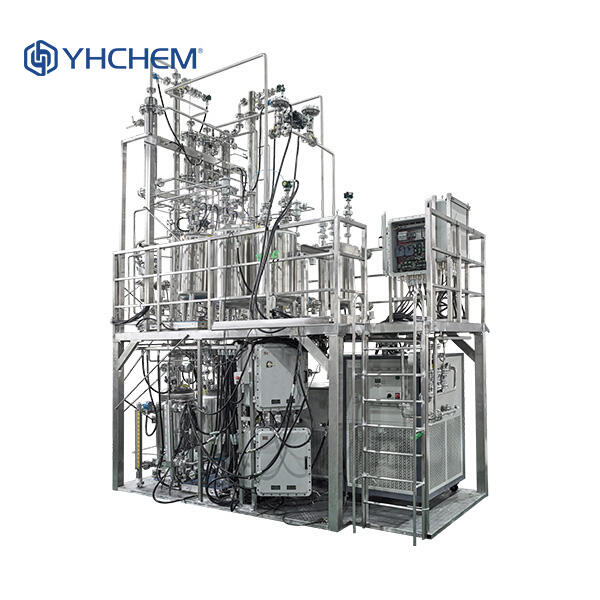

La distillation en colonne par lots a évolué avec le temps et au fil des années, elle a connu d'importantes améliorations. Cela a conduit à l'introduction de colonnes de distillation modernes équipées de systèmes informatiques uniques qui permettent à leur système de fonctionner automatiquement sans surveillance manuelle. C'est un progrès considérable dans l'efficacité du processus, qui aboutit désormais à une qualité plus constante des résultats finaux.

En conjonction avec la distillation en colonne par lots, la sécurité est primordiale. Pour les liquides toxiques, cela peut également prendre une tournure grave car cela implique des étapes de traitement. Cependant, aujourd'hui, à mesure que de plus en plus de fonctions de sécurité sont intégrées aux colonnes de distillation, les craintes d'une explosion dévastatrice de la colonne ont également été contrecarrées. Les systèmes d'arrêt automatique, les mécanismes de surveillance de la pression et les capteurs de température inclus dans son dispositif de protection sont responsables de la mise en œuvre sécurisée du processus.

Industries dans lesquelles nous utilisons la DISTILLATION EN COLONNE PAR LOTS

Applications industrielles de la distillation en colonne par lots. Elle est principalement utilisée dans le secteur pharmaceutique pour purifier les médicaments et médicaments conformément aux spécifications réglementaires strictes. La distillation en colonne par lots est utilisée dans l'industrie agroalimentaire pour séparer la bière ou le vin, afin de purifier ce liquide fermenté en l'un de ses constituants liquides. De plus, cette méthode est utilisée pour nettoyer le pétrole brut avec divers produits pétrochimiques à l'intérieur d'une raffinerie.

Guide étape par étape pour mettre en œuvre la distillabilité en colonne par lots

La distillation en colonne se déroule sur une base par lots dans plusieurs états. Donc, la première colonne est remplie du composé à purifier et chauffée jusqu'à ce que de la vapeur se forme facilement. La vapeur produite montera dans la colonne et traversera les plaques à l'intérieur. L'étape suivante consiste à collecter le distillat, puis à continuer avec un autre lot.

Précautions prises et entretien d'un dispositif de distillation par colonne par lots pour maintenir son bon fonctionnement et la qualité de sa production ? Entre les lots, la colonne doit être nettoyée pour éviter toute contamination et les composants qui cessent de fonctionner réduiront la productivité, ils doivent donc être immédiatement réparés. De plus, la flexibilité de cette colonne permet de répondre à différentes exigences de performance en fonction des besoins de pureté variés dans divers secteurs industriels.

En tant qu’entreprise cotée avec succès en bourse, nous bénéficions d’un soutien financier stable, ce qui renforce notre capacité de développement en matière de distillation en colonne par lots. Nous resterons fidèles à notre philosophie axée sur le marché et poursuivrons activement l’innovation produit afin de créer de la valeur pour nos clients et nos employés.

Nous avons fourni nos produits à des milliers d’entreprises réputées dans plus de 100 pays, ce qui nous a valu une large confiance en matière de distillation en colonne par lots. Nous nous engageons à améliorer continuellement nos services et nos produits sur la base des retours de nos clients.

Nous sommes un leader mondial en matière d'innovations technologiques et de colonnes à distillation par lots, innovant constamment grâce à des technologies avancées internationales et menant de façon continue des innovations technologiques indépendantes. Nous avons créé des laboratoires communs en partenariat avec des instituts de recherche tels que l'Institut de recherche sur l'industrie chimique de Shanghai ainsi que l'Université des sciences et technologies d'Asie orientale. Ces laboratoires sont dédiés à offrir à nos clients les produits et solutions les plus compétitifs.

Nous proposons une gamme de produits, notamment des appareils en verre pour colonnes à distillation par lots, ainsi que des systèmes de régulation de température et des instruments destinés aux réactions et à la distillation. Notre gamme de produits est conçue pour répondre aux exigences de divers secteurs industriels. Grâce à plusieurs stations de service, nous offrons à nos clients des produits et services scientifiques « clés en main », accompagnés d’un soutien technique rapide et d’un service après-vente tout au long du cycle d’utilisation.

En conclusion, la distillation par colonne par lots est un standard fiable de l'industrie qui garantit la sécurité et la pureté de tous types de liquides utilisés dans de nombreux secteurs différents. Avec une capacité d'adaptation pour produire différentes purités et une orientation continue vers le développement pour une haute productivité et sécurité, elle jouit d'une grande attention et d'un champ d'application plus large dans les pharmaceutiques (certaines coll. de pharm.), l'alimentation et la boisson, les services touristiques (secteurs) ainsi que le secteur pétrolier.