Distillation : Dans ce processus, deux mélanges liquides immiscibles sont d'abord portés à ébullition puis refroidis. Ce procédé est crucial dans de nombreux secteurs, principalement la raffinerie de pétrole, la fabrication de produits chimiques et la production de médicaments. La distillation nous permet d'obtenir des substances pures à partir de mélanges, car elle isole les molécules souhaitées. Cependant, il est difficile de construire ou de faire fonctionner une colonne de distillation. C'est pourquoi les ingénieurs recourent souvent aux simulations pour comprendre comment améliorer le processus ou à quoi pourrait ressembler une colonne de distillation mieux conçue.

La Simulation de Colonnes de Distillation est un programme informatique utilisé par les ingénieurs pour planifier et améliorer la conception des colonnes de distillation. La simulation aide les ingénieurs à observer le comportement des différents constituants à l'intérieur de la colonne de distillation. C'est important car la simulation nous permet de connaître la température et la pression dans la colonne, etc.... et enfin, nous pouvons comprendre à quoi ressemblera notre produit final après le processus complet.

Ces simulations sont créées à l'aide de modèles mathématiques et peuvent être utilisées par les ingénieurs chimistes. Ils sont très méthodiques dans leurs calculs, pour déterminer comment le mélange va circuler à travers la colonne à différents endroits. Ils prennent également de nombreuses autres mesures pour évaluer le bon fonctionnement de la colonne, comme la température et la pression ; La quantité de liquide qui retourne dans la colonne après condensation.

L'avantage principal de l'utilisation de simulations est qu'elles aident les ingénieurs à concevoir la meilleure structure de colonne. En modifiant le comportement de la colonne - par exemple, combien de liquide est recyclé dedans - les ingénieurs peuvent améliorer à la fois la pureté et le volume du produit final. Cela leur permet de produire des produits plus propres tout en maximisant leur rendement. Les simulations peuvent fournir des informations sur les points faibles ou d'inefficacité potentielle de la colonne, alertant les ingénieurs sur des zones de préoccupation et les aidant à ajuster si nécessaire.

Il existe un certain nombre de facteurs clés qui déterminent l'efficacité et les performances d'une colonne de distillation donnée. Ces valeurs sont également grandement influencées par plusieurs facteurs tels que le rapport de reflux (le liquide recyclé par rapport au distillat produit) et même la conception de la colonne en général. Il est important de comprendre comment ces quelques facteurs travaillent ensemble pour rendre la colonne aussi efficace qu'un processeur de profil d'élimination.

Un tel concept est celui du réglage du rapport de reflux. Si les ingénieurs augmentent cette proportion, cela signifie qu'une plus grande quantité de liquide retournera certainement dans la colonne - la moitié de laquelle s'évapore et se condense à nouveau, ainsi que la moitié de votre purificateur propre ! Mais alors, vous courez le risque d'obtenir MOINS de produit au total. À l'inverse, s'ils diminuent encore ce ratio, il pourrait être possible de produire plus de produit, mais celui-ci ne répondra plus aux normes de pureté. Trouver le mélange parfait de ces facteurs est là où vous obtiendrez vos meilleurs résultats.

Par exemple, l'un des accomplissements les plus difficiles en génie chimique est de distinguer un ensemble non dissimulé de diméthylheptanes des autres. Les isomères sont des molécules qui ont des formules chimiques identiques mais diffèrent en structure, ce qui complique leur séparation par distillation conventionnelle. Le mélange de hydrocarbures légers mentionné ci-dessus est considéré comme difficile à séparer sans risquer des coûts énergétiques excessifs, cependant, grâce à des simulations, les ingénieurs peuvent adapter la conception d'une colonne de distillation et améliorer l'efficacité de ce processus de séparation.

Nous sommes des pionniers mondiaux en matière d’innovation technologique et de mise à niveau des technologies de recherche et développement. Nous intégrons continuellement des technologies modernes, reconnues internationalement comme étant de pointe, tout en menant une innovation indépendante et des progrès technologiques. Nous avons mis en place des laboratoires communs en partenariat avec des instituts de recherche tels que l’Institut de recherche sur l’industrie chimique de Shanghai et l’Institut des sciences et technologies de l’Est de la Chine, spécialisé dans la simulation des colonnes de distillation. Ces laboratoires sont dédiés à offrir à nos clients les produits et solutions les plus compétitifs.

Nous disposons d'une position financière solide et d'une capacité de développement de simulation de colonnes de distillation en tant qu'entreprise cotée en bourse. Nous adhérons aux principes du marché et continuerons à innover dans nos produits pour apporter des avantages à nos clients et employés.

Nous avons fourni des simulations de colonnes de distillation à des milliers d'entreprises renommées dans plus de 100 pays, ce qui nous a valu une large acceptation et une grande confiance. En nous appuyant sur les besoins et les exigences de nos clients, nous améliorons continuellement nos produits et services. Nous nous engageons à accroître la valeur et le retour sur investissement pour nos clients.

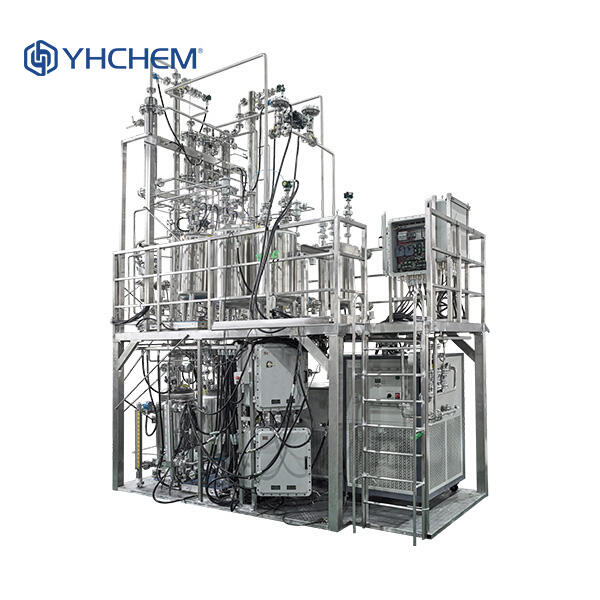

Nous proposons une vaste gamme de produits, notamment des simulations de colonnes de distillation, des systèmes de régulation de température et des instruments de réaction par distillation. Notre gamme de produits est conçue pour répondre aux exigences de divers secteurs industriels. Nous offrons à nos clients un service intégré comprenant plusieurs centres d’approvisionnement en services, assurant ainsi un soutien technique rapide ainsi qu’un service après-vente pour nos produits.