Les Avantages des Réacteurs Fluidisés dans les Applications de Traitement Industriel Moderne

Nous savons qu'en ce qui concerne le monde industriel, les choses vont plus vite que jamais et chaque jour il y a un désir de découvrir de nouvelles façons d'être de plus en plus efficace. Un réacteur fluidisé est un exemple typique d'un tel progrès révolutionnaire qui crée des remous dans la mare proverbiale. Il aide à transformer de nombreux types d'industries en présentant plusieurs avantages. Plongez encore plus profondément en continuant votre lecture ici dans notre article sur les réacteurs fluidisés.

Au cœur de cette technologie novatrice se trouve le réacteur fluidisé, une machine chimique complexe qui suspend des catalyseurs solides ou des particules dans un milieu liquide de telle sorte qu'ils coulent comme des fluides. Des courants gazeux ou liquides à haute vitesse sont injectés à travers un lit de particules solides, et ces dernières sont agitées et s'élèvent au-dessus sans passer en phase dense. Cela provoque un mouvement similaire à celui d'un fluide, et donc on dit qu'il est "fluidisé".

Révéler les avantages de l'utilisation de réacteurs fluidisés

De nombreuses industries bénéficient de l'utilisation de réacteurs fluidisés. Ces réacteurs permettent de mélanger facilement des solides, des liquides et des gaz, ce qui accélère également le processus de production. Cela signifie que les réacteurs fluidisés peuvent conduire à un rendement de production plus élevé, abaisser le prix de votre produit final et réduire le temps de traitement en améliorant le transfert de masse au sein du réacteur, ainsi qu'en optimisant les réactions chimiques. Le comportement similaire à un fluide dans les réacteurs présente également un grand rapport entre la surface et le volume, favorisant le transfert de chaleur afin que les conditions de réaction puissent être ingénieries. De plus, les réacteurs fluidisés sont polyvalents et peuvent facilement être adaptés aux exigences spécifiques des réactions en ajustant les catalyseurs, la température ou la pression. Leur adaptabilité fait également des CycloClones un système robuste pour une flexibilité de production et ils sont adaptés aux besoins des différentes industries.

Bien que les réacteurs fluidisés soient utilisés depuis longtemps pour des applications industrielles, il y a récemment, année après année, de nouveaux modèles qui résolvent les problèmes de l'approche classique en se développant de manière agressive. Les améliorations les plus significatives proviennent de l'intégration de capteurs sophistiqués et de systèmes de contrôle qui optimisent le fonctionnement des réacteurs fluidisés. Dans cette optique, la dernière génération de capteurs est capable de surveiller continuellement les processus et d'informer les systèmes de contrôle qui interviendront immédiatement afin de ne pas perdre en performance. Ensuite, les progrès dans la conception et la technologie des matériaux ont abouti à des réacteurs plus solides capables de traiter à un débit plus élevé nécessaire pour ces conditions exigeantes.

Sécurité d'abord lors de la planification des applications de réacteurs fluidisés

Pour que toutes les technologies soient intégrées dans des processus industriels, la sécurité est avant tout une priorité. Cependant, la bonne nouvelle est que les réacteurs fluidisés disposent également de plusieurs mécanismes de sécurité pour éviter ces pièges potentiels. D'une part, les réacteurs fonctionnent comme des systèmes fermés où tout est strictement contrôlé pour limiter l'exposition et les risques pour l'homme. Cela réduit les risques d'incendie ou d'explosion d'après des chiffres discutables. De plus, les réacteurs fluidisés peuvent fonctionner sous pression atmosphérique pour éviter des augmentations dangereuses de pression dans le réacteur et offrir un environnement de travail plus sûr pour les opérateurs.

Faire fonctionner un réacteur fluidisé est très simple. Tout d'abord, la chambre du réacteur est remplie de catalyseurs solides ou de particules, puis un fluide est ajouté. En augmentant progressivement le débit pour le faire dépasser une certaine vitesse, le fluide peut suspendre ou faire léviter les particules contenues à l'intérieur, formant ainsi ce qui ressemble à un courant sanguin - tout en maintenant une identité indépendante de chaque particule individuelle. Cela déclenche les réactions chimiques nécessaires en introduisant les matériaux appropriés dans le lit fluidisé avec un échange direct (et un contrôle) pour un réglage optimisé afin de maintenir de bonnes conditions de réaction tout au long du processus.

Se concentrer sur un excellent service dans l'utilisation d'un réacteur fluidisé

Avantages des réacteurs fluidisés pour les industries : bien que les avantages significatifs des réacteurs fluidisés pour les industries soient difficilement contestables, il est également soutenu que la qualité du service et des produits ne peut être surévaluée. La qualité d'un réacteur fluidisé joue un rôle important dans l'efficacité opérationnelle et mérite votre attention. De plus, le service doit être fiable pour garantir une excellente performance du réacteur et permettre une résolution rapide des problèmes qui assure la continuité de la production. Il est important de choisir uniquement les meilleures entreprises offrant un excellent service client et des produits de haute qualité qui complètent efficacement l'utilisation des réacteurs fluidisés.

Les réacteurs fluidisés sont capables d'être utilisés dans diverses industries. Ces réacteurs fluidisés sont largement employés dans les secteurs tels que la production pétrochimique (craquage et reforming), la fabrication de polymères, la production de plastiques, la fabrication de produits chimiques, comme par exemple les engrais. Ces réacteurs jouent un rôle crucial dans le traitement des denrées alimentaires telles que les céréales et les snacks. De manière similaire, l'industrie pharmaceutique utilise les réacteurs fluidisés dans le processus de fabrication de médicaments. Les réacteurs fluidisés apportent un soutien considérable dans presque toutes les applications, ce qui en fait une technologie précieuse adaptée à presque tous les usages, améliorant ainsi l'efficacité et la rentabilité dans toutes les industries.

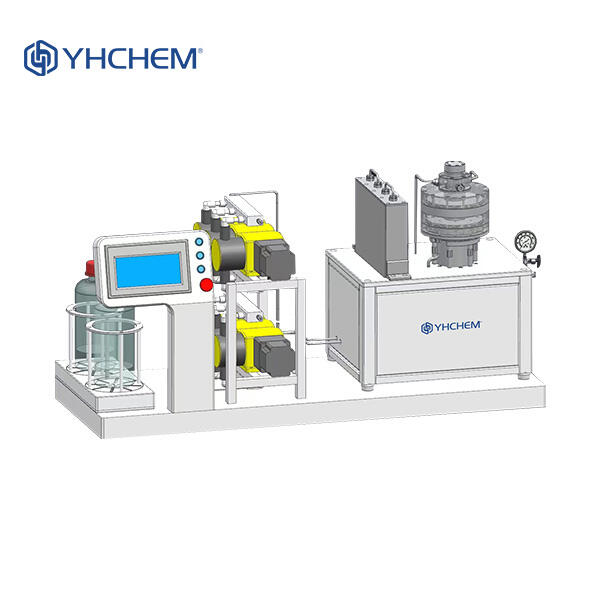

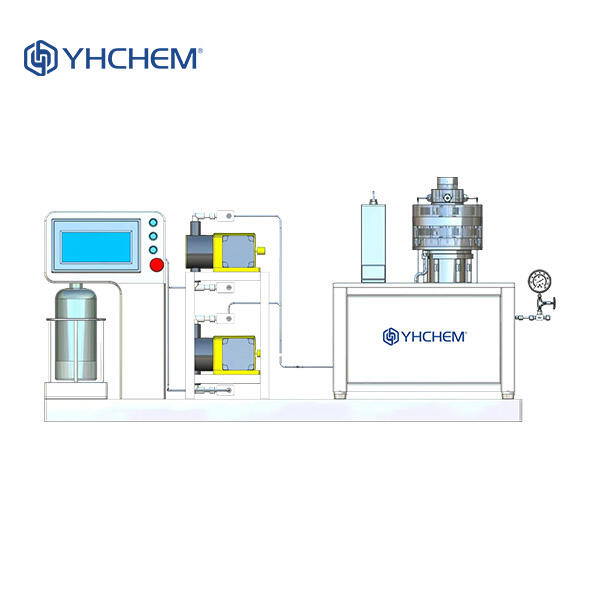

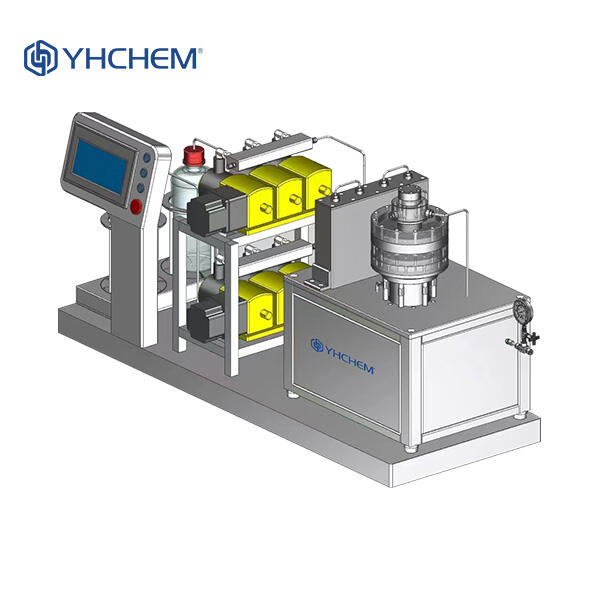

Nous proposons une gamme de produits incluant du matériel en verre pour le contrôle de la température, des réactions en puits et des équipements de réacteurs fluidisés. Notre gamme de produits est spécifiquement conçue pour répondre aux besoins de divers secteurs industriels. Nous offrons à nos clients un service « tout-en-un », comprenant plusieurs centres de service, une assistance technique rapide ainsi que des services après-vente pour nos produits.

Nos produits sont utilisés par des centaines de réacteurs fluidisés réputés dans plus de 100 pays et régions à travers le globe, ce qui nous a valu une large reconnaissance et une forte confiance. Guidés par les exigences de nos clients, nous améliorons constamment nos produits et services, afin de fournir davantage de valeur et de retours sur investissement à nos clients.

Nous disposons d'une solide assise financière et d'une capacité de développement durable, en tant qu'entreprise cotée en bourse. Nous continuerons à nous conformer aux principes orientés vers la demande du marché, en stimulant sans cesse l'innovation des réacteurs fluidisés et les progrès technologiques afin de créer davantage de valeur et d'opportunités pour nos clients, nos investisseurs et nos employés.

Nous possédons des capacités technologiques mondiales de pointe en matière de réacteurs fluidisés ainsi que des compétences en recherche et développement (R et D) à l'échelle mondiale, développant constamment les technologies internationales de demain et menant une innovation technologique autonome continue ainsi que des mises à niveau régulières. Grâce à des collaborations avec des instituts de recherche renommés tels que l'Institut de recherche de l'industrie chimique de Shanghai et l'Université des sciences et technologies d'Asie orientale, nous avons mis en place des laboratoires communs, axés sur la fourniture à nos clients des produits et solutions les plus compétitifs.

Réacteurs fluidisés : Une odyssée d'innovation L'innovation derrière les réacteurs fluidisés a ouvert la voie à plusieurs industries cherchant une croissance durable dans leurs domaines. Grâce à leur surveillance attentive, des fonctionnalités de sécurité accrue et des fonctionnalités en constante augmentation dans les industries modernes automatisées, les robots sont devenus un outil indispensable pour effectuer toutes sortes d'opérations plus rapidement ! Avec les progrès de la technologie et les industries devenant de plus en plus compétitives, il est essentiel de rester constamment à jour avec de telles solutions innovantes - les réacteurs fluidisés sont nécessaires pour toute entité opérant dans ce domaine. En prêtant attention à la qualité du service, aux considérations de sécurité et à une large gamme d'applications, les entreprises peuvent pleinement tirer parti des réacteurs fluidisés pour réussir dans un monde en constante évolution.