Technical Specification:

Model |

YWT-60 |

YWT-80 |

YWT-100 |

YWT-150 |

YWT-200 |

|

Volume of charging tank (L) |

0.5 |

1 |

1 |

2 |

5 |

|

Tower height (m) |

1 |

1 |

1 |

1 |

2 |

|

Condensing area (m²) |

0.2 |

0.25 |

0.3 |

0.4 |

0.5 |

|

Rotation speed range (rmp) |

50-500 |

|||||

Operating pressures (mbar) |

≤0.001 |

|||||

Working temperature range (℃) |

≤300 ℃ |

|||||

Input voltage |

220V/1P |

|||||

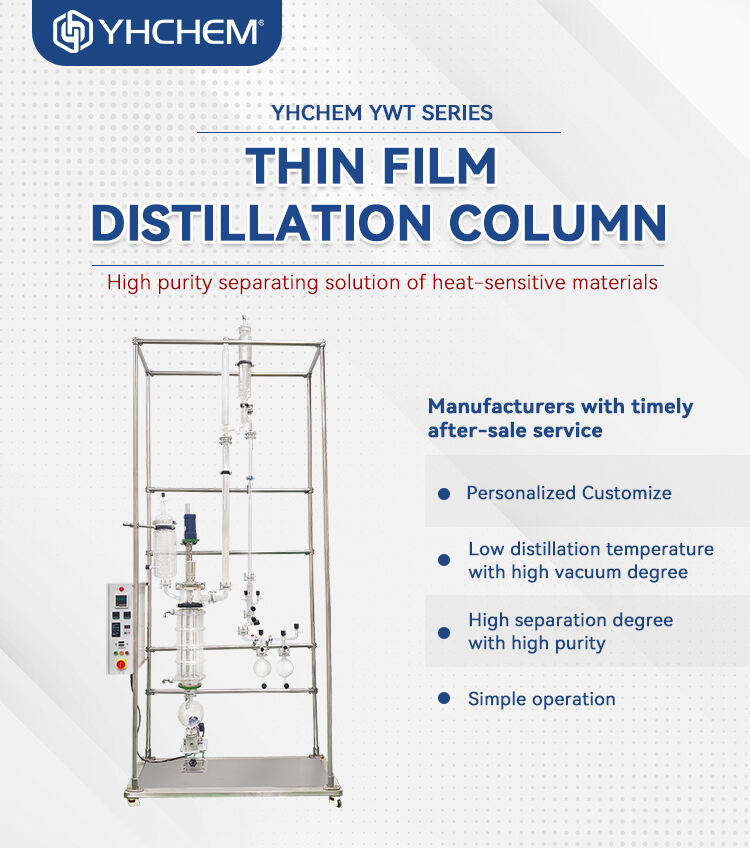

Thin film distillation column is a coupling device between thin-film evaporator and distillation column.ln the process of distillation, thin film distillation column can solve the problem of thermal decomposition of heat-sensitive materials, which caused by too high temperature in the tower bottom and too long residence time inthe reboiler. lt prevents deterioration reactions such as decomposition, polymerization and oxidation of materials when heated, and effectively protects the characteristics of product materials. At the same time, compared with the traditional thin-film evaporator, the thin-film distillation column increases the function of distillation, which can better improve the purity of products and reducemore purification process steps. The excellent characteristics of negative pressure film scraping and rectification of thin film distillation column can be widely used in biopharmaceuticals, food fields, plant extraction and chemical industries.

♦♦WORKING PRINCIPLE

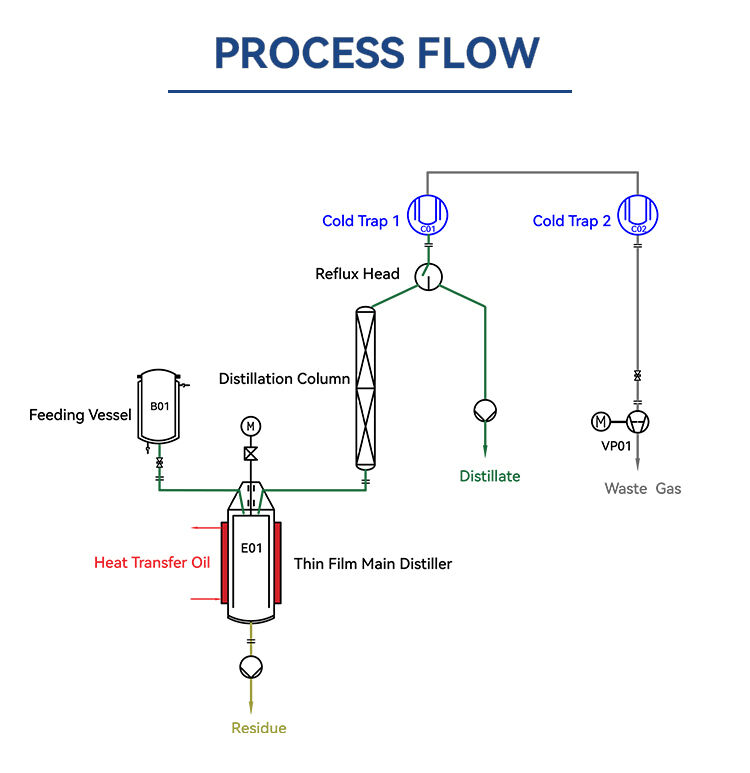

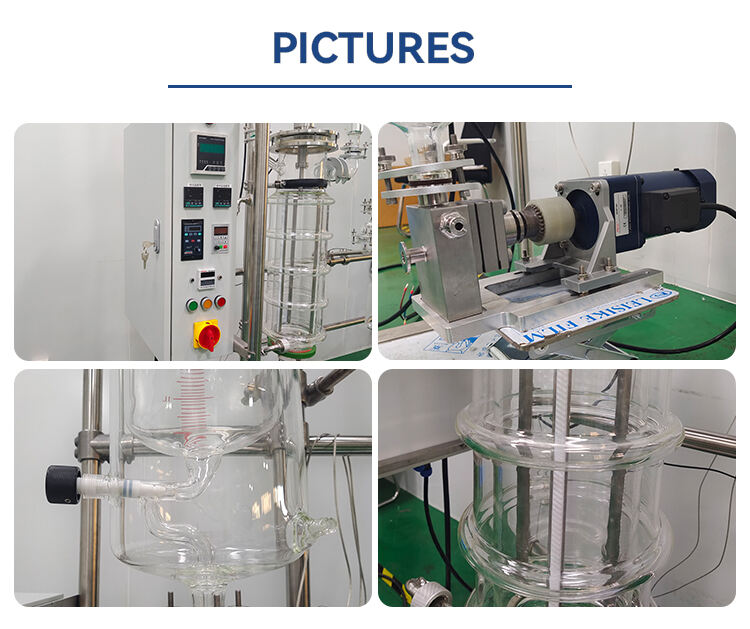

The material enters the main evaporator from the feeding tank, and is scraped intoa very thin and turbulent liquid film by the film scraper, and pushes downward in a spiral shape. The light product components escaping from the heating surface enter the rectification column upwards and carry out mass transfer and heat transfer between gas and liquid. The product materials are condensed by the condenser,and if the purity is not enough, they will flow back. Finally, the high purity products will be collected.

♣1.Supply Customized Services

Can supply customized service according to customer's mate-rial characteristics

♣2.Low distillation temperature and high vacuum degree

The vacuum environment with negative pressure can avoid the decomposition and poymerization of heat-sensitive materials, and reduce the distillation temperature of materials which with high boilingpoint. The material will have short residence time and high heat transfer efficiency

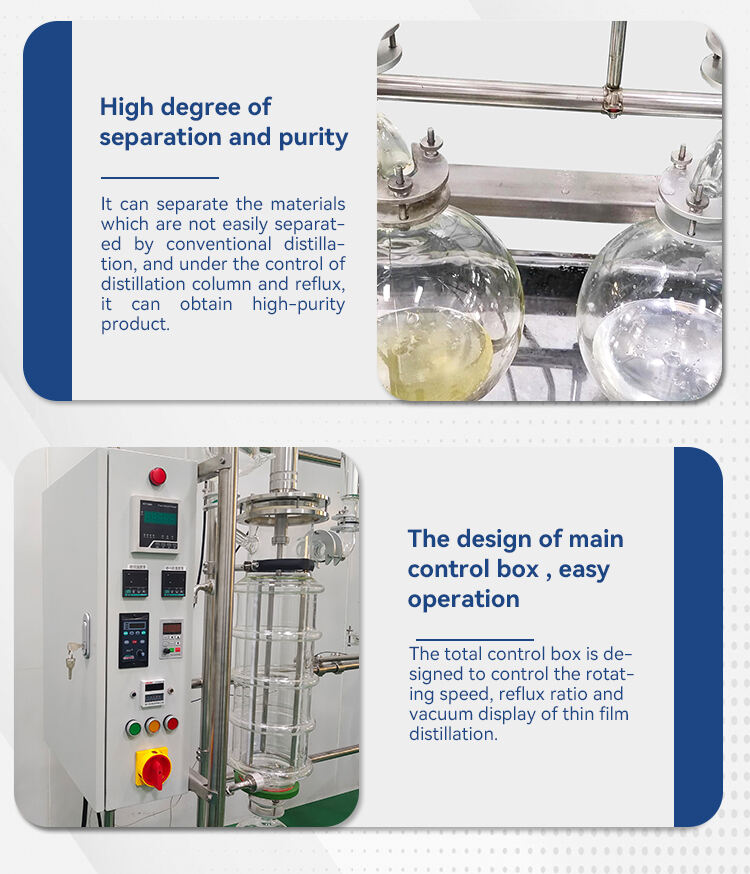

♣3.High degree of separation and purity

lt can separate the materials which are not easily separated by conventional distillation, and under the control of distillation column and reflux,it can obtain high-purity product.

♣4.The design of main control box , easy operation

The total control box is designed to control the rotating speed, reflux ratio and vacuum display of thin film distillation.

♣Biopharmaceutical

♣Plant extraction

♣Food

♣Chemical industry

♣Cold Trap 1

♣Reflux Head

♣Distillation Column

♣Feeding Vessel

♣Distillate

♣Cold Trap 2

♣Waste Gas

♣Heat Transfer Oil

♣Thin Film Main Distiller

♣Residue

♣Heating circulator

♣Cooling circulator Gear pump

♣Vacuum pump

♣Thin Film Distillation Column

YHCHEM, a high-tech enterprise, was established in 2009 and headquartered inShanghai with more than 50 employees both at home and abroad and an area of5,000 square meters. We have a globally competitive production base of modernbiopharmaceutical equipment, which attributes us to be a equipment and processprovider of automatic system of synthesis, extraction, separation, and purificationfor global biopharmaceutical companies With over 10-year hard work, passionand win-win spirit,YHCHEM provides more than 8,000 equipment for hundreds otwell-known companies in more than 100 countries and regions around the worldand has successfully entered Western Europe, North America and other high-levelregulatory market, and solutions are widely used in bioengineering, pharmaceuti-cal, chemical, food, environmental protection and other fields

The YHCHEM Glass Thin Film Distillation Column Plant is a state-of-the-art laboratory tool designed for plant extraction, distillation, and purification. This extraction tower is built using high-quality materials to ensure durability and precision in every phase of the process.

Representing the brand name's dedication to quality, it features that make it possible for users to extract crucial oils, concentrate oil solutions, and purify them. The plant removal process involves separating the components of a mixture heat is utilizing stress. This is important in the production of varied products, such as for example natural oils and substances being essential.

The technology behind this extraction tower is seen as the movie distillation column design is thin. This form of distillation is ideal for significantly reducing the quantity of oils needed to extract products that are high-quality. A game-changer into the laboratory industry, many thanks to its design is efficient and features.

Made borosilicate is utilizing, which is an essential component of this product. Borosilicate glass is famous for the durability and strength, rendering it the product is ideal laboratory-grade equipment. Additionally, it really is resistant to thermal chemical and shock corrosion, making sure your distillation process goes uninterrupted.

Also features a vacuum pump that creates an environment is low-pressure which really helps to improve the distillation procedure. In this process, the low pressure causes the boiling point of the substance to cut back, making sure the components evaporate faster and the extracts are of the quality is greatest.

The YHCHEM Glass Thin Film Distillation Column Plant Extraction Tower offers a wide range of benefits to laboratory processes. Its advanced features allow for simplified, efficient, and cost-effective laboratory activities, delivering high-quality results every time. It is the perfect solution for those looking to improve their plant extraction processes.

Our friendly team would love to hear from you!