The Industrial distillation and purification of alcohol equipment stainless steel vacuum fractional distillation column is just a response high-grade ethanol large- purification and range. This equipment is constructed out of top-quality steel stainless includes a vacuum cleaner distillation fractional for precise and effective splitting up of products. This method is perfect for distilling liquor high-purity clinical, methodical, or even industrial functions. A distillation is used since of its treatment that occurs under vacuum cleaner problems to obtain free of cross-contamination whilst the reduction in important compounds throughout distillation. Consequently, of this, the product final of this pureness biggest, making it a suitable choice for business consisting of chemical towards pharmaceutical.

The Industrial distillation and purification of alcohol equipment stainless steel vacuum fractional distillation column includes a precision distillation column that uses a permeable ceramic element towards enhance efficiency splitting up. This element is incredibly resilient and immune towards chemical severe, guaranteeing a lengthy life expectancy while providing efficiency exceptional. Furthermore, the product was produced along with simpleness in thoughts. Its own interface easy to use and setups ensure it is a simple job towards operate, likewise if you are perhaps not experienced in distillation. The device is offered along with a completely automated treatment and for that reason might be configured towards carry out distillation that is certain, providing a regular and manufacturing every time reliable.

The steel stainless when it concerns Industrial distillation and purification of alcohol equipment stainless steel vacuum fractional distillation column truly assists to create specific that the products is extremely resilient and immune towards rust, making it an option ideal be been applicable in industrial setups. This item is easy towards preserve and cleanse, guaranteeing a specific niche site lengthy along with very little downtime. The Industrial distillation and purification of alcohol equipment stainless steel vacuum fractional distillation column is simply a product offers that are high-quality, reliable, and effective results for industrial-scale distillation and purification of liquor. The product is crafted along with high top premium and precision in your thoughts, creating specific it is most likely to provide efficiency outstanding a very long time. Select YHCHEM as your relied on companion in industrial distillation equipment and undergo the difference in high top premium and efficiency.

Technical Specification

|

Model |

YFT-5S |

YFT-10S |

YFT-20S |

YFT-50S |

YFT-100S |

|

Tower volume (L) |

5 |

10 |

20 |

50 |

100 |

|

Tower height (m) |

2 |

2 |

2 |

2 |

2 |

|

Condensing area (m²) |

0.25 |

0.4 |

0.65 |

1.15 |

1.75 |

|

Reflux ratio control |

Yes |

||||

|

Temp pressure display |

Yes |

||||

|

Continuous sampling |

Yes |

||||

|

Working temperature range (℃) |

-20-200 ℃ |

||||

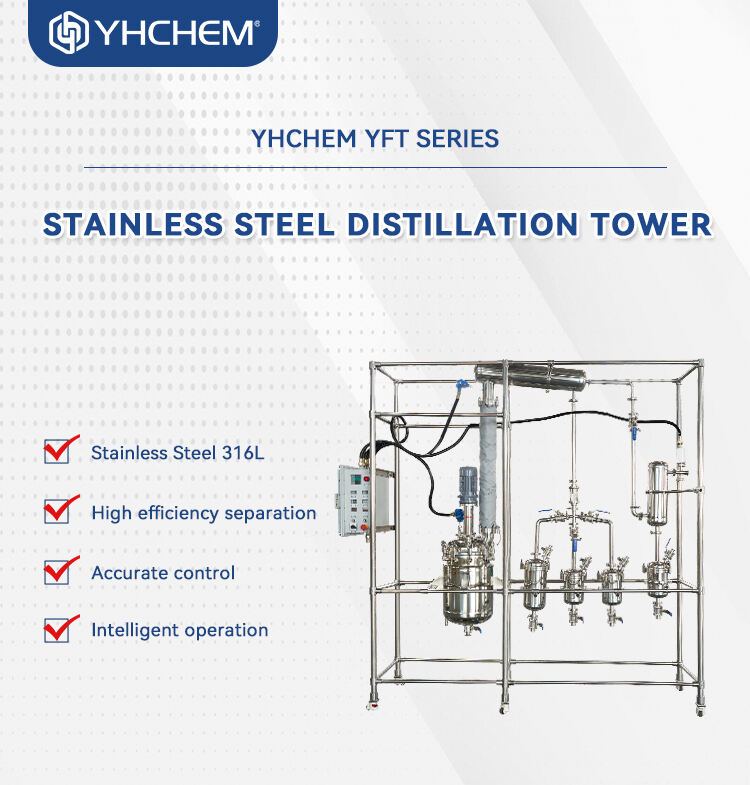

PRODUCT DESCRIPTION

The lab and pilot scale distillation column are made of stainless steel, and can be designed for normal, reduced and pressurized use. Thetower kettle can be designed with electric heating, transfer oil heatingsteam heating and other heating methods. The specifications of thetower section are 38~200mm and the height is 0.5-8.0m. Each sectionof the tower section can be equipped with a feed port/temperature measurement port, and various non-standard products can also be de-signed and manufac tured according to the specific requirements ofcustomers. Modern intelligent instruments are usedto set the temperature of the tower body, so that the experimental process is closer to the ideal state to a greaterextent and achieves better experimental results.

♣1.STAINLESS STEEL 316L

Good corrosion resistance, high temperature and pressure resis-tance, durability, high heat transfer efficiency, easy to clean and main-tain, can operate stably for a longtime.

♣2.HIGHEFFICIENCY SEPARATION

In a stainless steel distillation column, by subjecting the mixtureto multiple stages of distillation and condensation, the tempera-ture differences between the evaporation and condensation ofeach component can be in-creased, thereby achieving better separation efficiency.

♣3.THE STRUCTUREOF THE TOWER IS SIMPLE

suitable for the separation ofsmall and high value materials.

♣4.INTELLIGENT OPERATION

In the process of device develop-ment.computer simulation was introduced to make the operationof distillation experiments moreintelligent.

♣5.IT CAN BE BATCHDISTILLATION ORCONTINUOUS DISTILLATION

Intermittent distillation or continuous distillation can be selected accordinqto process requirements and equipment design. Continuous distillation has higher production efficiency andmore stable operation, while intermittent distillation is more suitable forsmall-batch production and situa-tions where product quality requirements are higher.

♣1.Operation mode Normal and negative pressure operation, the best vacuumdegree can reach 1mmHg;

♣2.The thermal insulation material of the tower body is a transparent heating film,and the experimental phenomenon can be observed;

♣3.The device frame is specially designed, and the verticality of the tower is easy toadjust;

♣4.All industrial control point panels are centrally installed, and it's easy for operatorto operate:

♣5.The designers of distillation tower thinks deep and long-term. The expansionspace of the device function is large, which not only work for targeted experiment.but also maximizes the contribution of the device

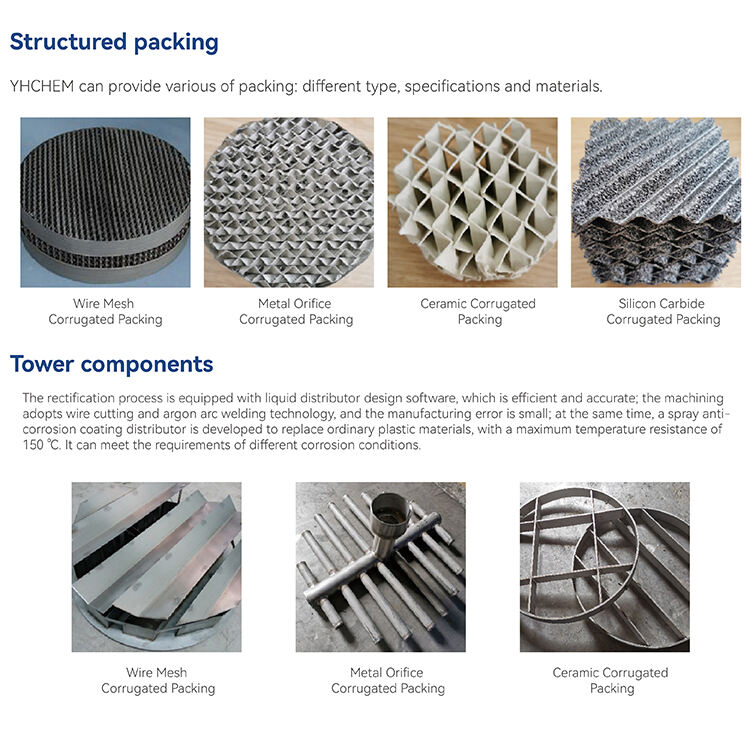

♣1.Structured packing

YHCHEM can provide various of packing: different type, specifications and materials.

Wire MeshCorrugated Packing

Metal OrificeCorrugated Packing

Ceramic CorrugatedPacking

Silicon CarbideCorrugated Packing

♣2.Tower components

The rectification process is equipped with liquid distributor design software, which is efficient and accurate; the machiningadopts wire cutting and argon arc welding technology, and the manufacturing error is small: at the same time, a spray anticorrosion coating distributor is developed to replace ordinary plastic materials, with a maximum temperature resistance of 150°C. It can meet the requirements of different corrosion conditions.

Wire MeshCorrugated Packing

Metal OrificeCorrugated Packing

Ceramic CorrugatedPacking

Can be customized according to customer's requirement.

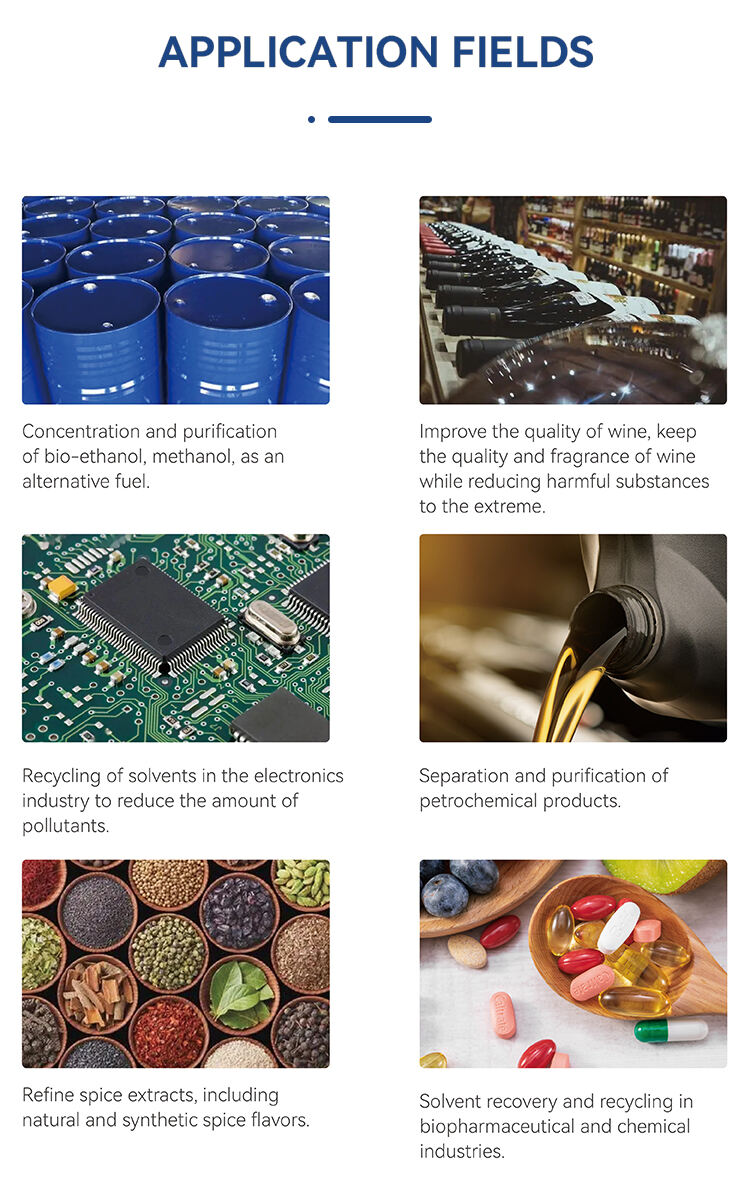

♣1.Concentration and purificationof bio-ethanol. methanol, as analternative fuel.

♣2.Improve the quality of wine, keepthe quality and fragrance of winewhile reducing harmful substancesto the extreme.

♣3.Recycling of solvents in the electronicsindustry to reduce the amount ofpollutants.

♣4.Separation and purification ofpetrochemical products.

♣5.Refine spice extracts, includingnatural and synthetic spice flavors.

♣6.Solvent recovery and recycling inbiopharmaceutical and chemicalindustries.

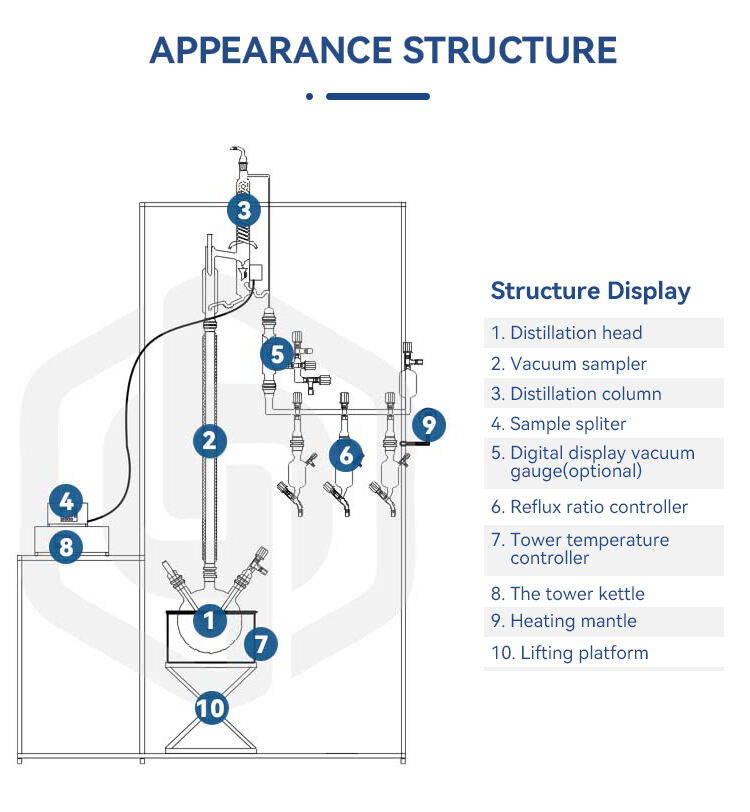

♣1. Distillation head

♣2. Vacuum sampler

♣3. Distillation column

♣4. Sample spliter

♣5. Digital display vacuumgauge(optional)

♣6. Reflux ratio controller

♣7. Tower temperaturecontroller

♣8. The tower kettle

♣9. Heating mantle

♣10. Lifting platform

♣1.Cooling circulator

♣2.Rotary vane vacuum pump

♣1.Distillation column

♣2.Thin film distillation column

YHCHEM, a high-tech enterprise, was established in 2009 and headquartered inShanghai with more than 50 employees both at home and abroad and an area of5,000 square meters. We have a globally competitive production base of modernbiopharmaceutical equipment, which attributes us to be a equipment and processprovider of automatic system of synthesis, extraction, separation, and purificationfor global biopharmaceutical companies With over 10-year hard work, passionand win-win spirit,YHCHEM provides more than 8,000 equipment for hundreds otwell-known companies in more than 100 countries and regions around the worldand has successfully entered Western Europe, North America and other high-levelregulatory market, and solutions are widely used in bioengineering, pharmaceuti-cal, chemical, food, environmental protection and other fields

Our friendly team would love to hear from you!