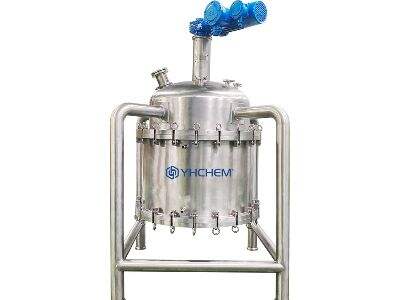

O reator eficaz de tanque agitado (STR) tem como centro o agitador. A escolha do tipo de impulsor selecionado é de natureza crítica, bem conhecida por determinar diretamente a eficiência de mistura, a transferência de calor, o rendimento da reação e a produtividade geral. Sendo um grande fornecedor de reatores integrados, a YHCHEM é orientada ao design em sua Série de Reatores, iniciando com um amplo espectro de designs de agitadores que foram desenvolvidos para atender necessidades específicas de processo em diversas indústrias, incluindo biofarmacêuticas, nova energia e petroquímica. Para maximizar o desempenho operacional, é importante compreender os benefícios e aplicações de cada um deles.

Agitadores de Âncora e Pá: Especialistas em Fluidos Viscosos.

Os agitadores de âncora e de pá são ideais para misturar fluidos não newtonianos e de alta viscosidade. Os agitadores são utilizados muito próximos à parede do recipiente.

Os agitadores individuais do sistema são projetados para se adaptar ao formato do tanque, eliminando zonas de estagnação e incrustação, e promovendo a transferência de calor através da camisa, o que é fundamental em processos sensíveis à temperatura, como polimerizações ou fabricação de doces. A YHCHEM utiliza este design com produtos viscose em que é necessária uma mistura homogênea em volume e elevada troca térmica.

Com suas pás simples e planas, os agitadores de pá proporcionam cisalhamento moderado e também são adequados para misturar líquidos de baixa viscosidade ou manter sólidos em suspensão. Sua construção robusta confere-lhes desempenho estável em aplicações simples de mistura na indústria alimentícia e eletrônica, como adesivos. Quando é importante uma mistura suave, mas eficaz, os agitadores de pá são usados na YHCHEM.

Agitadores Turbina: o Tudo Redondo Agitadores de Alto Desempenho.

Um dos sistemas mais comuns e gerais é o agitador de turbina. Eles são projetados com mais de uma lâmina disposta radialmente ao longo de um eixo central para produzir altas taxas de cisalhamento e fluxo radial do fluido.

O principal benefício dos agitadores de turbina é que podem ser utilizados na dispersão de bolhas de gás e na produção de boa potência de bombeamento, razão pela qual são aplicáveis não apenas em aplicações de dispersão gás-líquido, como fermentação ou hidrogenação, mas também na dispersão de líquidos.

Os agitadores de turbina são comumente empregados na Série de Reatores da YHCHEM em sínteses químicas altamente exigentes dentro da petroquímica e da fabricação de materiais avançados. O design facilita alta transferência de massa e mistura homogênea, o que é essencial para garantir qualidade uniforme do produto e reações escalonáveis. Isso é ainda complementado pelos sistemas integrados de Controle de Temperatura da YHCHEM para gerenciar reações exotérmicas.

Agitadores do Tipo Hélice: A Monarcas do Fluxo Axial e da Circulação.

Agitadores de hélice utilizam o mesmo conceito das hélices marinhas, apenas proporcionando um forte padrão de movimento axial do fluido entre a parte superior e inferior do sistema. Este é um design eficaz que se adapta bem a líquidos de baixa a média viscosidade.

Os agitadores de hélice são aplicados especialmente na mistura de líquidos imiscíveis, na manutenção de suspensões sólidas estáveis e no fornecimento de alta circulação em tanques de grande porte. Sua natureza de baixo cisalhamento e alto fluxo é adequada para aplicações onde é necessária uma mistura suave, evitando a degradação ou danos às partículas ou células.

A YHCHEM utiliza agitadores de hélice nos processos das indústrias biofarmacêutica e ambiental, por exemplo, em grandes caldos de fermentação, tanques de fermentação ou recipientes para tratamento de águas residuais. Eles têm a capacidade de gerar uma circulação constante e uniforme, proporcionando condições homogêneas no interior do recipiente, o que é crucial para a confiabilidade do processo e o rendimento.

O Motor que melhor se adapta ao seu Processo: não é o Agitador certo?

A escolha do agitador certo baseia-se nas características do fluido, incluindo sua viscosidade e densidade, nas regulamentações do processo (dispersão, suspensão, transferência de calor) e na intensidade de cisalhamento que precisa ser alcançada. Não existe uma solução única que sirva para todos.

Os tipos de agitadores diferem na sua aplicação conforme a quantidade de força necessária para operar o sistema, seja com um movimento suave, como um agitador tipo âncora, ou mais potente, como uma turbina. A colaboração com a YHCHEM possui mais de 10.000 sistemas instalados em todo o mundo; você não obterá apenas um impulsor, mas uma peça altamente projetada de um sistema reator integrado de alto desempenho, concebido para garantir seu sucesso na sua indústria.

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

UK

UK

HU

HU

TH

TH

TR

TR

GA

GA

BE

BE

BN

BN