- PRODUCT DETAILS

- RELATED PRODUCTS

PRODUCT DETAILS

Overview

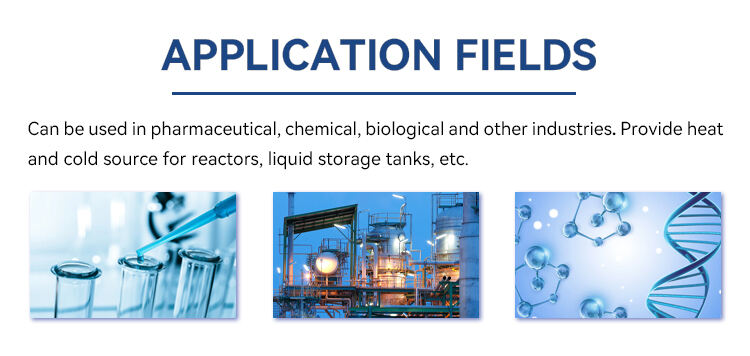

YHR series a kind of heating & cooling circulator device that can provide heating source or cold source. It usually consists of a main control system and two independent temperature control systems, respectively used to control the temperature of high and low temperature areas. It’s widely used in scientific research laboratories, industrial production, pharmaceutical manufacturing, and other fields. It can provide a high-temperature environment for baking, heat treatment, drying and other operations, as well as a low-temperature environment for freezing, cooling, refrigeration and other applications.The fully enclosed pipeline design and high-efficiency plate heat exchange,while reducing the demand for heat transfer fluid and improve the heat utilization rate cf the system.While reducing the demand for thermal fluid,improve the heat utilization rate of the system to achieve rapid temperature rise and fall.The heat transfer medium is in a closed system with an expansion vessel,and the heat transfer medium in the expansion vessel does not participate in the circulation,whether it is high temperature or low temperature.The temperature of the expansion tank keep at 60℃ which effectively reduces the risk of moisture absorption and volatilization of the heat transfer medium during the operation.

Features

● Pre-cooling device,refrigeration system and heating system can be used together

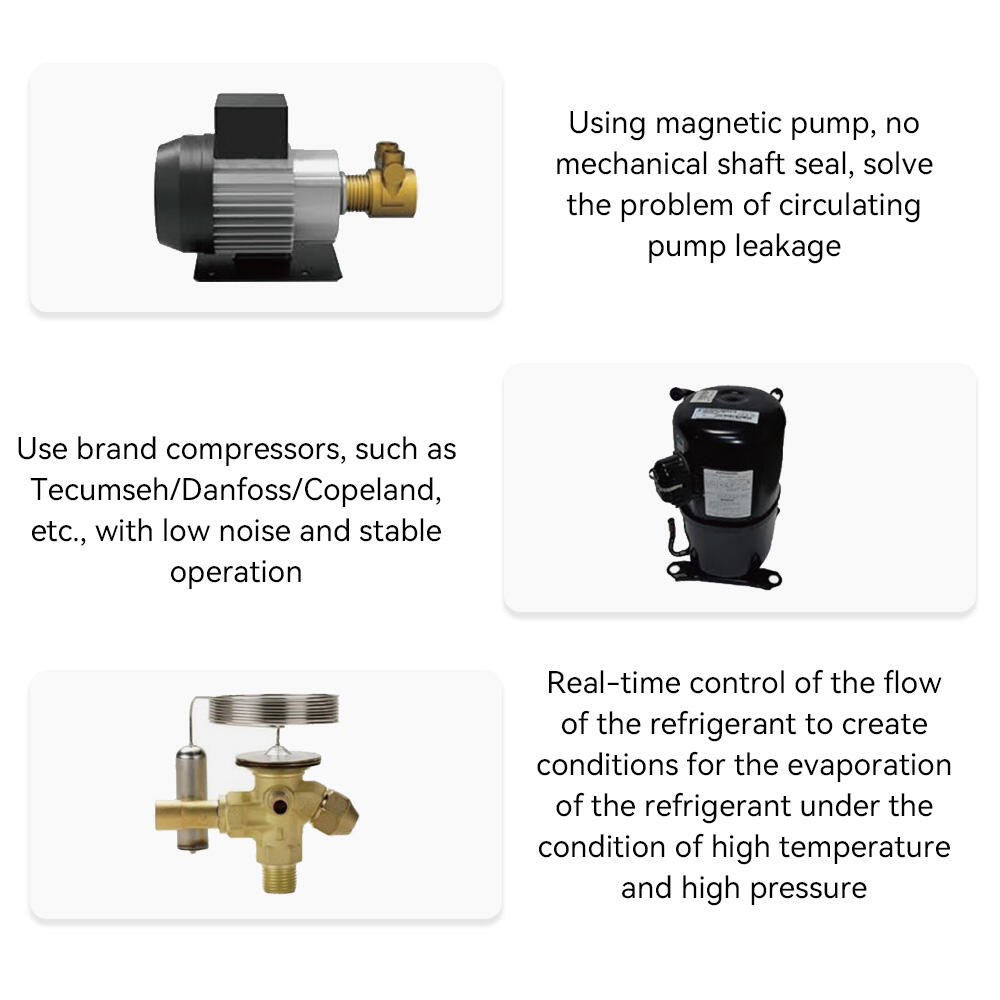

● It can be used together with 20L,50L,100L and other reaction togetherThe material inthe reactor can be cooled to -25℃,or heated to 200℃ Refrigeration system compressor,oil separator,solenoid valve,expansion valve,All with importedbrandsCool down fast,and can force rapid cooling

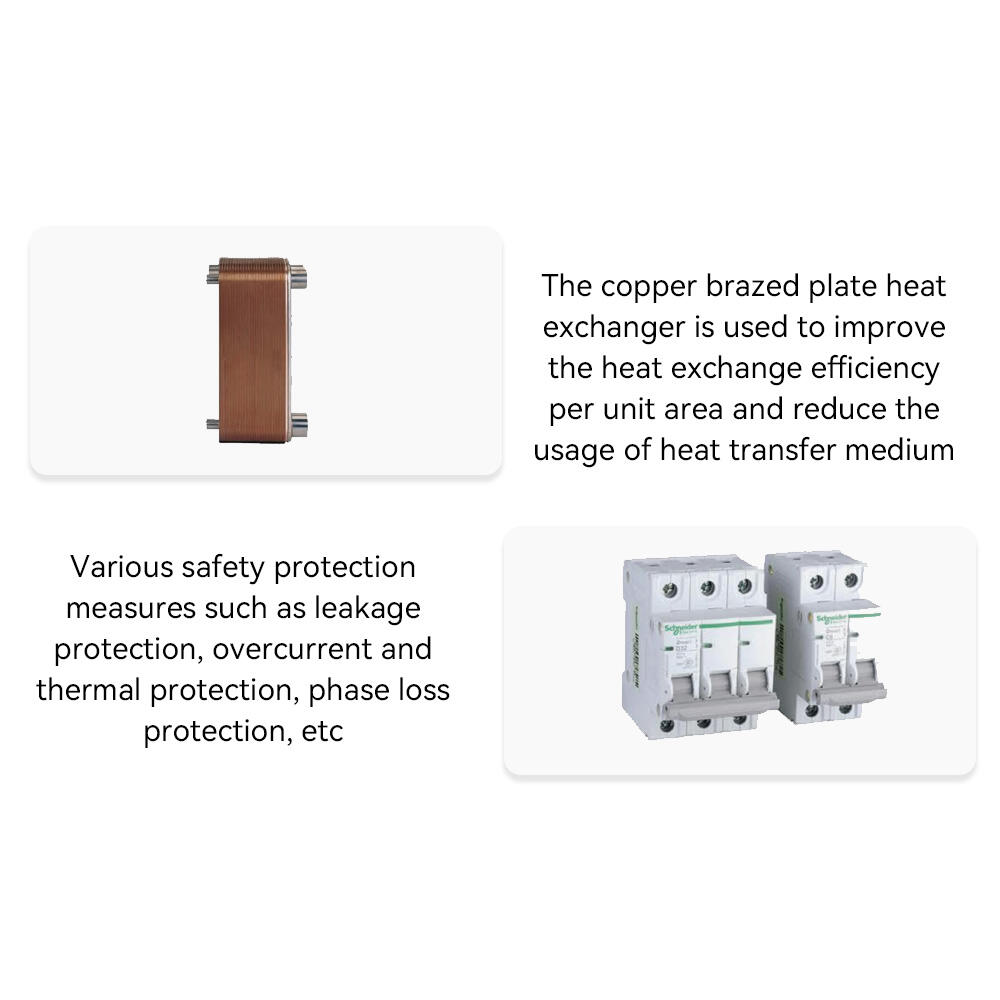

● With high and low voltage protection,overloadprotection,overcurent protection,connection.Ground protectionand other protection functions. The evaporator with a fully brazed plate heat exchanger

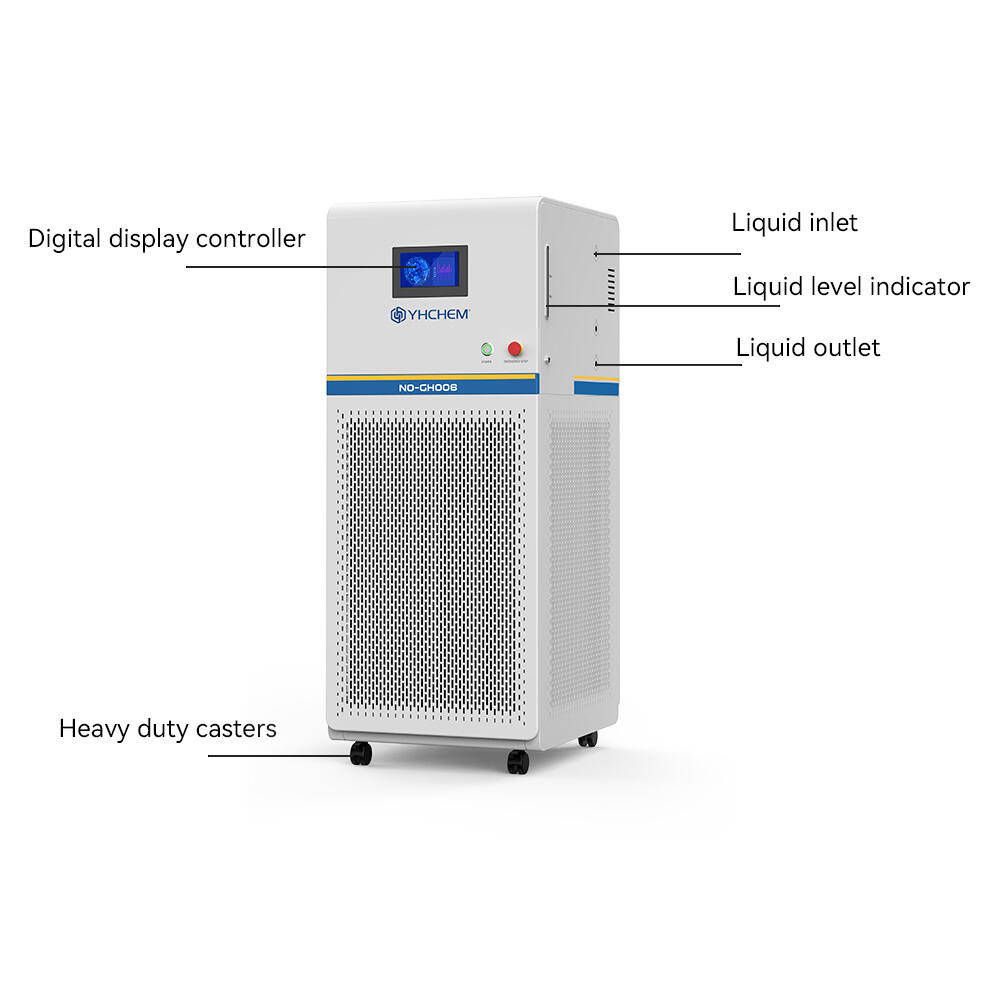

● The liquid level tube monitors the energy in real time to avoid the lack of heat transfer fluid

● The closed circulator system,reduce the volatilization of the refrigerant and protect the health of the experimenterThe liquid storage tank and circulation pipeline made of 304 stainless steel,with good corrosion resistance

● The shell with electrostatic plastic spray SPCC,with good anti-corrosion effectWith stable and reliable function,Long-term continuous operation

● Certification: CE

● It can be used together with 20L,50L,100L and other reaction togetherThe material inthe reactor can be cooled to -25℃,or heated to 200℃ Refrigeration system compressor,oil separator,solenoid valve,expansion valve,All with importedbrandsCool down fast,and can force rapid cooling

● With high and low voltage protection,overloadprotection,overcurent protection,connection.Ground protectionand other protection functions. The evaporator with a fully brazed plate heat exchanger

● The liquid level tube monitors the energy in real time to avoid the lack of heat transfer fluid

● The closed circulator system,reduce the volatilization of the refrigerant and protect the health of the experimenterThe liquid storage tank and circulation pipeline made of 304 stainless steel,with good corrosion resistance

● The shell with electrostatic plastic spray SPCC,with good anti-corrosion effectWith stable and reliable function,Long-term continuous operation

● Certification: CE

Typical Applications

Product Parameter

| Model | YHR-25A | YHR-35A |

| Temperature range (℃) | ’-30~100 | |

| Temperature Stability(℃) | ±1℃ | |

| Temperature sensor | PT100 | |

| Heating power (Kw) | 2 | 3 |

| Refrigeration capacity (w) RT | 2010 | 2800 |

| Refrigeration capacity (w) 0℃ | 1650 | 2300 |

| Refrigeration capacity (w) ﹣30℃ | 400 | 600 |

| Tank volume(L) | 10 | 20 |

| Rated flow rate (L/min) | 25 | 25 |

| Dimension L×W×H(mm) | 540*420*800 | 570*490*840 |

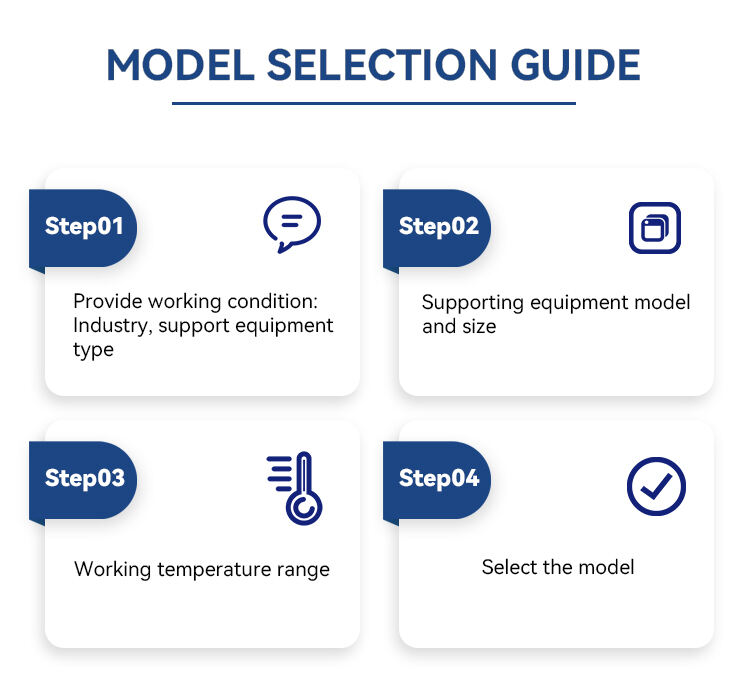

Model Selection Guide

Supporting Products

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

UK

UK

HU

HU

TH

TH

TR

TR

GA

GA

BE

BE

BN

BN