reactors are almost like small recycling plants that run chemicals through a more useful cycle. YHCHEM has a company that makes these reactors and they are highly beneficial in science. So, what are Custom Microchannel Reactors and why are they so important?

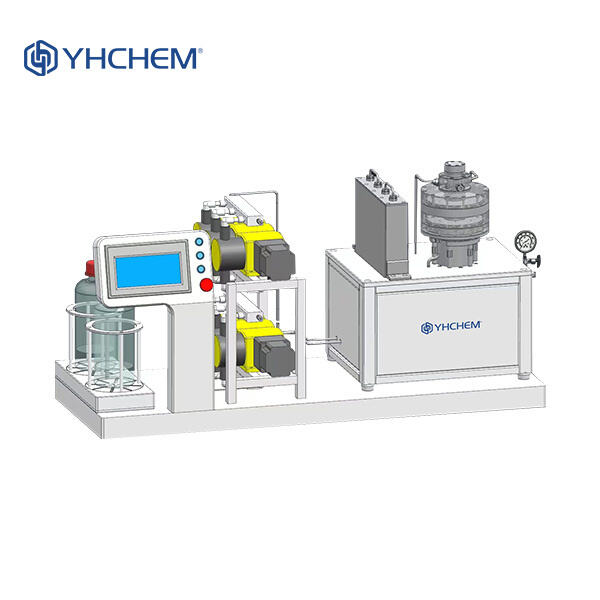

Miniature Wet Chemical Reactors are tiny machines for the chemical industry to mix different ingredients and make new substances. They’re very small, and they have lots of channels where the ingredients can flow through. YHCHEM produces these reactors in various shapes and sizes, depending on customer need. Custom Microchannel Reactors are mini labs that can experiment and create in a highly precise manner.

There is a variety of compelling motivation for adapting CMR for chemical industry applications. One is that they are very effective. The downsides: Because they are small, they can churn contents together quickly and evenly. They save companies that use them time and money. One reason is that they are easy to maintain at a particular temperature. And that is a big deal, because some reactions need to occur at a specific temperature to function properly. YHCHEM’s reactors can achieve these perfectly.

There are a lot of things to think about when making a Personalized Microchannel Reactor. One key one is what the reactor is made of. It needs to not only strong, but also capable of withstanding the chemicals being applied. YHCHEM uses unique materials so that their reactors are safe and have a long lifetime. Something else to think about is the dimensions and the configuration of the channels that are in the reactor. The way these channels are designed can affect how well the ingredients combine. YHCHEM’s engineers specialize in creating the optimum channels for each reactor.

Many different chemicals can be produced using diaphragm pumps. They can help make everyday products like soap and plastic or advanced materials that are used in medicine and electronics. The reactors of YHCHEM are used in laboratories worldwide for product research and development. They are also employed in large factories to mass-produce chemicals that people need. This demonstrates the great versatility of the Custom Microchannel Reactor.

Custom Microchannel Reactor technology will only continue to improve in the future. YHCHEM is constantly innovating to make their reactors the best. “They are going to use machines and A.I. to manage the reactors,” said one trend. This can be a yet more accurate and expedient descend process. Another trend is developing new materials for the reactors that can withstand higher temperatures and pressures. YHCHEM is at the forefront of these developments to ensure their Custom Microchannel Reactors remain the best on the market.