A truly intriguing process to be used in a wide array of industrial applications, it is molecular distillation. The technique is called the molecular distillation principle and it might sound complicated but we will walk through exactly how you can implement this in more detail. In this Article, We go more in-depth about what is molecular distillation how it work and all the benefits you can get.

And crazy to think some folks have secretly wondered why and how molecular distillation work! It is, in fact, a refined method used to distil two liquids with different boiling points. Through creating a vacuum, the liquid boils at low temperatures that makes it so much easier to separate. Our short path equipment therefore operates on the molecular level, which actually is what makes this kind of distillation so efficient at isolating particular molecules within your liquid.

Molecular distillation has numerous advantages when compared to traditional methods of distillation. We will talk about first, the very low power requirement in operation which makes it a cost effective. It is because, this revolutionary system have some properties like the process must be fast and efficient as well provide better quality products. In particular, this method is distinguished by the ability to separate out heat-sensitive substances from impurities in such products as essential oils often difficult for traditional distillation techniques.

New advances in Molecular Distillation

Though the basic tenets of molecular distillation have been around for quite some time, it is new technology that has driven this field in a major way. This has been speeding up the distillation process with innovations such as spinning cones which help to create a thin liquid film. In addition, the microfluidic channels have increased liquid surface area and thus enhanced separation efficiency.

Safety should be the top concern when using molecular distillation principle. Unlike other news sources, CartechUK believes that complying with the manufacturer's specifications is necessary to minimize damage. Since the boiling point of its liquid will also drop, careful handling is important to avoid accidents. It is ideal for the machine to be used only in a properly-ventilated area with trained personnel, allowing no dangerous fumes to build up.

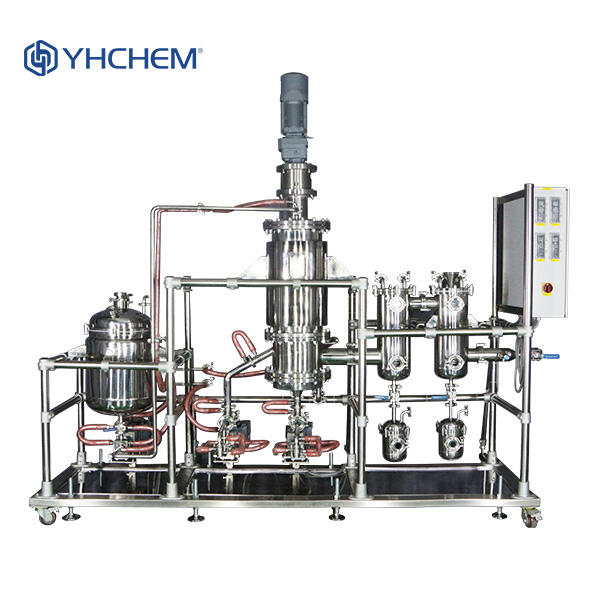

Molecular distillation equipment is not too complicated to operate. The liquid is first heated in a flask to turn it into vapor. The condensed vapor, in turn is cooled down by a condenser and so reverts to liquid form. Impurities are retained while the purified liquid is collected into a receiving flask. When buying a molecular distillation machine, of course the important one is great customer service and warranties.

We world-class technological Molecular distillation principle and R and D capabilities across globe, constantly developing international technologies of the future conducting continuous independent technological innovation and upgrades. Through collaborations well-known research institutions like Shanghai Chemical Industry Research Institute and East China University of Science and Technology, we have established joint laboratories, focused providing clients the best competitive products and solutions.

Our product line encompasses range of categories, including distillation temperatures, distillation, glassware instruments, catering to the demands of a variety of industries. With number of services stations, We offer our customers scientific all-in-one products services and provide timely technical support and after-sales support all way Molecular distillation principle their journey.

We have solid Molecular distillation principle structure and sustainable growth capability as a listed company. We will remain committed market demand-oriented principles drive continuous product innovation and technological advancement generate more opportunities and value for customers, investors, and employees.

We've supplied products to myriads of well-known businesses over 100 countries, earning wide Molecular distillation principle trust. We're committed to improving services and products based on customer feedback.

Applications Of Molecular Distillation: This is a very versatile Industrial process used across the board of industries; such as Food, Pharmaceuticals and Chemicals. It is widely used in the purification of essential oils for removing impurities & undesired compounds. In summary, molecular distillation is essential for premium extraction of cannabis extracts thereby illustrating its diverse applications.