The Heart of Chemical Plants

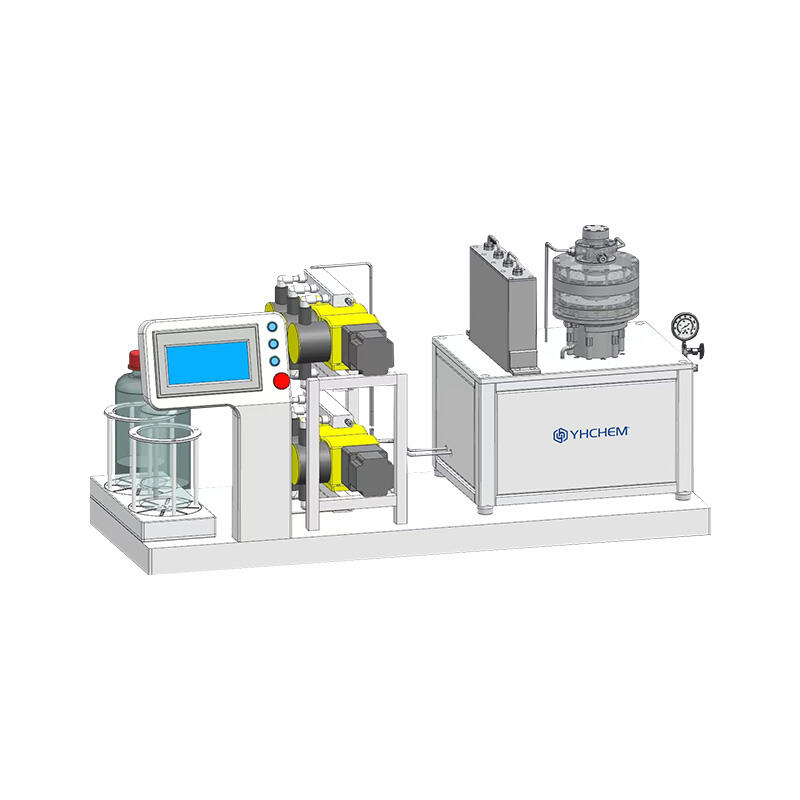

A Reactor: All chemical plants have a reaction section called as the reactor. This is where a variety of chemicals are combined to produce new items. These reactors are sometimes quite large with multiple components and some of these parts not being made of the same materials that they plan on making. ReactorLet us study about reactors and there types in chemical plants.

Advantages

Reactor tanks in chemical plants are a few good examples. They aide in the gentle mixing of chemicals which speeds recovery. Reactors also ensure that the end product is of high quality by excluding any negative entities. They can produce a large amount of chemicals in short time intervals which helps to cut down the cost for production.

Innovation

There have also been recent ideas to improve the reactors further. So for many chemical reactions, reactors use certain sound waves to keep the chemicals from mixing, ensuring a specific outcome? Another reason is that some reactors are also built to be less harmful for the environment, and therefore do not add as much harm into our planet.

Safety

Safety is a paramount thing in chemical plants, especially when using reactors. There are a slew of regulations to keep reactors running as safe as possible. They are very durable, able to withstand high temperatures without getting damaged more easily. There are more safety systems which are stopping the reactor if something goes wrong.

Use

Reactor are used in various sectors such as manufacturing of medicine, food additives, fungicides and many other chemicals. In pharmacy, reactors are used to cook drugs, and in food - they prepare everything from taste enhancers. Reactor: The chemical industry is used to obtain the desired products such as cleaning solutions, rubber chemicals and plastic materials.

How to Use

Reactor use is for the trained and learned. Reactor operators need to be sure they do everything just as described so the reactor stays very safe and performs well. Starting n reactor require a DataSet, the kind of checks it should have been done for GDPR etc.

To keep it functioning well and safe, a reactor must be maintained. The company making the reactor should do as much maintenance so it can last long. To also be in good shape for a reactor, routinely cleaning the device itself and changing parts is crucial, as well as making sure its safety features are working properly.

Quality

Among other factors, the use of a reliable reactor is essential to ensure correct and efficient production. It should be composed of such material which provides the rector with sufficient strength and meets all industrial standards. The company should be excelling certificates to show the reactor having tested and quality standard etc.

Reactor are utilized in the chemical industry in various applications. They are also used as a key component in the preparation of rubber by blending some specific materials. Reactor s produce solvents such as acetone and ethanol used in the manufacturing of cleaning liquids. Reactor is utilized for planning of plastics like polyethylene and PVC

The chemical plants are supported by a key element called as reactor. It is the nucleus of all chemical cross-reactions. There are many types of reactors, which depend on what is being processed. In this installment, we explore the world of reactors and how they define a chemical plant.

Advantages

2. The advantages of reactors in chemical plants They enable accurate mixing of compounds which improves productivity. Furthermore, reactors maintain the quality of products prevents impurities. They can produce massive amounts of chemicals quickly, making them relatively inexpensive for manufacturing processes.

In the past few years, there have been substantial technological advances in reactor design. For example, some reactors now use ultrasonic waves to control the chemical reactions with greater precision and efficiency. Moreover, others are environmentally friendly or sustainable based on the design of molecular reactors so that there would have less ecological footprint to produce chemicals.

Safety

What we require the most is safety and when it comes to running Reactors in a chemical plant, they are supposed be handled with utmost care. Nuclear reactors are subject to strict safety protocols, that results in a safe operation. They are made of strong and durable materials which can resist high temperatures, wear-and-tear,and chemical corrosion. In addition, control and safety features are built into reactors to shut down the plant if necessary...

Reactors are utilized in various industries such as pharmaceuticals, food production and chemical manufacturing for many applications. Reactor are of enormous importance within the Pharmaceutical industry, here they act in synthesis for drug and on other hand food industries produced additives. Reactor is a core apparatus in most of the chemical manufacturing, as these are used for making different materials (e.g. from complex industrial solvents to synthetic polymers).

How to Use

As an aside, running a reactor requires extensive training and knowledge of the process. The operator must follow all the guidelines and instructions given by the manufacturers in order to obtain optimal performance as well as safety. Before a reactor is activated, regardless of the type, it should be carefully examined and tested to see if there are any problems with its operation.

We've supplied products thousands of reputable companies over 100 Reactor in chemical plant we have gained a wide amount of appreciation trust. We're committed improving our products and services according to the feedback our customers.

We are a world innovator technological Reactor in chemical plant, R and D and technology upgrades. We constantly introduce innovative technologies across the globe while making independent technological innovations upgrades. Through collaborations with world-renowned research institutions such as Shanghai Chemical Industry Research Institute East China University of Science and Technology We established joint laboratories, committed to providing customers with the most competitive products and solutions.

Our product line encompasses range of categories, including distillation temperatures, distillation, glassware instruments, catering to the demands of a variety of industries. With number of services stations, We offer our customers scientific all-in-one products services and provide timely technical support and after-sales support all way Reactor in chemical plant their journey.

As successfully listed company a solid financial Reactor in chemical plant and sustainable development capacity. We will adhere the market-driven principles drive continuous product innovations increase worth for our customers employees.

Regular maintenance and servicing are needed to keep the reactors working perfectly, both for performance and safety. When it comes to maintaining reactors for continued operation, manufacturers / suppliers should provide maintenance support. This includes performing cleaning, replacing parts periodically and checking the safety features.

Quality

Whether a reactor is of good quality or not can affect production and safety. Reactor: Reactors should be high-grade material and comply with industry standard design. Manufacturers should provide quality assurance certificates to demonstrate that the detectors undergo stringent tests and meet fine quality criteria.

Applications

The chemical industry utilizes a wide array of reactor types. Reactors are used to polymerise monomers into rubbers i.e. synthetic rubbers production Reactor for Industrial Solvents- It is used in the production of industrial solvents like acetone, ethanol and methanol. Likewise, in the production of plastics a reactor is employed to produce quuweet an array of rubbers and polymerized olefins.