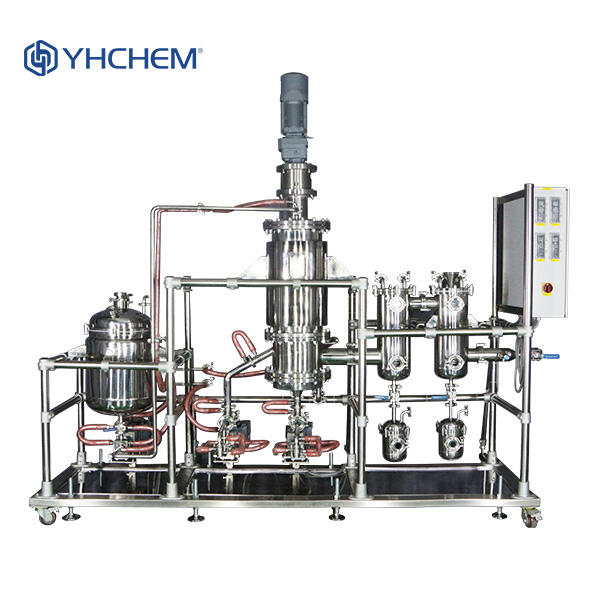

Vacuum distillation equipment is a special apparatus that is essential in different industries such as oil and gas, chemical or pharmaceutical production. Supersonic spray distillation (SSD) is one hundred percent DFE Pharma invented and patented and is a completely new approach to liquid separation based on the boiling points of liquids. It takes the yields out of a product in significantly more significant amounts than traditional methods like vacuum or high temperature short path column. DPHARMA’s filtration unit METF X12 is specialised and designated due to its distinctiveness of design: one component hands out the foremost end – the penetration filter – system that does quite a sophisticated work, as it is handling the EC- labeled case polymorphic super cooling protein reactions from slurry status. *.Lower boiling points of liquids mean less energy consumption and possibility for end products Improving product quality and the end product quality also brings less unwanted reactions occur in separation through the cleaner resulting in. Boiling at lower pressure allows not only lower boiling points but Filters about the end product being made. Purification systems have also improved over the years and are now widely used s. Industrial Vacuum Distillation app The vacuum distillation Equipment has progressed through many milestones over the years. The computer-controlled chambers have made the sufficient work of monitoring and control, resulting in an improvement of the product as it provides a product that is uniform and pure. Rigid design chambers which facility flow during distillation and newer materials like borosilicate glass and the availability of stainless steels have seen efficiency increases.

In conclusion, all vacuum VAC UU M DISTILLS OTE S have a destructive safety risk. As does the procedure of making things blown up based on the laws of physics that control boiling. These threats can be controlled both during the arrangement of the apparatus and the privileges inspects and supports. One of the most effective ways to lower these risks equates to the use of equipment designed and done for safety items and conditions as the route out. Conversely, the industry user’s vacuum distillation equipment depends on the steam injects the following factors to the gear as choosing the appropriate performance. Conversely, as a final area, for all prefaces this means ideal conditions in cannabis distillation and ability. This combines accuracy and direct care with attention to maintaining the procedures encouraging an end resultcool. Furthermore servicing and maintenance must be done Done safety in mind.

The application of vacuum distillation equipment is varied widely and includes the petroleum engineering field, chemical production and pharmaceutical manufacturing. They are used in organic component separations, drug purification, production of the highest quality drugs with consistent product nature. The advantages of vacuum distillation equipment outweigh their possible experience of danger. Especially if safety measures are followed, the equipment can bring many benefits to the business.

Vacuum distillation apparatus is a kind of equipment that can separate the liquid at temperatures below conventional methods. Lowering the pressure in a distillation chamber allows for lower boiling points of liquids, meaning less energy consumption and better end product quality. Also, which allows a cleaner separation to occur without an unwanted reaction or impurity and therefore makes the end product more pure.

Vacuum distillation Equipment has come a long way over the years. The distillation process has been revolutionized by the integration of computer-controlled systems which facilitate accurate monitoring and control, resulting in an improvement to product quality and consistency. Improvements in the design of chambers for optimal flow during distillation and the creation of new materials, such as borosilicate glass and stainless steel have also led to higher efficiency.

Security Ask VAC UU M DISTILLS OTE S

Thus, while there are significant benefits to using vacuum distillation equipment for these processes it is equally important that safety should be prioritized when operating this technology. This inherent implosion risk is a result of the physics behind boiling liquids at low pressures but can be greatly reduced by proper design and maintenance. One of the best ways to reduce these risks is by using equipment that meets all industry safety conditions, regularly inspecting and performing maintenance on them.

These important considerations are noted in the case of business, industry doing use vacuum distillation equipment include. The first, and relatively clear, is to choose the equipment that has been specifically fitted for distillation of your liquids as it must provide required performance. And finally, as with everything in cannabis extraction (but particularly when working on the large scale that steam distillation demands) safety protocols must be respected and practiced-this includes wearing proper protective gear and careful management of the proceeding processes to ensure a clean final product.

As with any other industrial machinery vacuum distillation equipment requires its own regular servicing and maintenance to maintain a good performance level safety standards. This will involve regular checks, maintenance of the distillation chamber and any necessary repairs/improvements. In fact, many suppliers also make their service and maintenance packages so that the equipment performs to highest levels.

We provide range products including glassware temperature control, well reactions and vacuum distillation equipment equipment. Our product line specifically designed meet the needs of various industries. We offer customers all-in-one service that includes multiple service centers, supplying prompt technical assistance, after-sales services products.

We have strong financial foundation a long-lasting capacity for development a publicly traded company. We will continue to adhere market demand-oriented principles, driving continuous vacuum distillation equipment innovation technological advances to create more value and opportunities for customers, investors and employees.

We possess leading technological innovations R and D strength globally, actively introducing international advanced technologies continually conducting independently driven technological innovations and innovations. have established joint labs in collaboration with research institutions such as the Shanghai Chemical Industry Research Institute East China University of Science and Technology. These laboratories are dedicated offering customers most vacuum distillation equipment products and solutions.

We provided products a myriad of well-known businesses over 100 countries we have gained a wide amount appreciation and trust. We're dedicated enhancing our vacuum distillation equipment and products based on customer feedback.

The wide applications of vacuum distillation equipment are accompanied by their use in the petroleum engineering industry, chemical production and pharmaceutical manufacturing. It is essential in academia for separating organic components, refining medications and creating pharmaceuticals with the highest quality of consistent product. Vacuum distillation equipment has many benefits and by abiding with safety protocols, businesses can easily take advantage of these features making the equipment worthwhile.