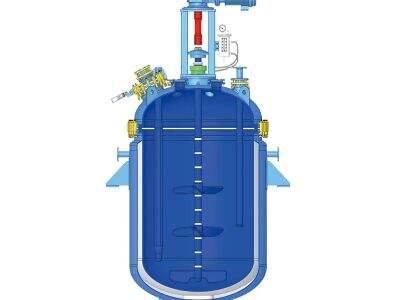

Chemical plants apply various tools and techniques to ensure the glass reactors they’re buying is of high quality. These are tools that help them verify that the companies that make glass reactors are complying with the rules. As a reliable seller of laboratory products, YHCHEM understands that following the regulations of the industry is essential. There are three vital ways in which chemical plants verify glass reactor manufacturers, we will find in some detail next.

How Chemical Plants Verify Glass Reactor Manufacturers

Chemical plants do not want to make the mistake of choosing sub-standard glass reactors - they cannot risk cheapening out on quality and safety. They test how well the manufacturers achieve this by considering a number of things. They think about the quality of materials, the craft of building the reactors, and the reliability of the equipment.

Significant Checks to Testing for Compliance with Business Rules

One of the key ways that chemical plants verify glass reactor manufacturers is by asking if they agree with industry rules. That is, the manufacturers have to follow safety guidelines, apply the best methods for producing the reactors, and obtain all the proper approvals. It is only when suppliers adhere to these regulations that chemical plants can rest assured that the glass reactors they purchase are both safe and high quality.

How Chemical Plants View Craftsmanship and Materials

The quality of glass reactors is highly dependant on the ability of the workers as well as the materials employed. Chemical plants verify the skill by inspecting how meticulously reactors are fabricated and testing the general quality of the work. They also inspect the materials to ensure that they are of high quality and meet the required standards. By inspecting these, chemical plants can determine the goodness of the glass reactor manufacturers make.

Discover How To Be More Efficient And Increase Productivity

In addition to insisting on high quality glass reactors, chemical plants also seek to find a way to improve and speed up their work. They look at things like how efficient the manufacturing process is, how much they produce and how long it takes to make the reactors. By studying these numbers, they can then discover how to get better and run their operations more effectively. This enables chemical plants maximize the utility value of the jacketed glass reactor that they buy.

How Chemical Plants Verify Reliability and Life

Chemical plants need a quality chemical glass reactor as not many things are more important for that. And they have to be confident that the equipment will work well and last a long time. They assess reliability based on how tough the equipment is, how it performs on a range of surfaces, and the manufacturer’s track record. By evaluating these factors, chemical plants can make informed decisions about what equipment to purchase.

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

UK

UK

HU

HU

TH

TH

TR

TR

GA

GA

BE

BE

BN

BN