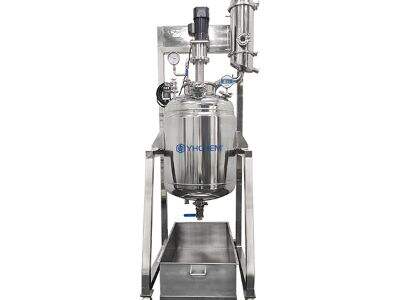

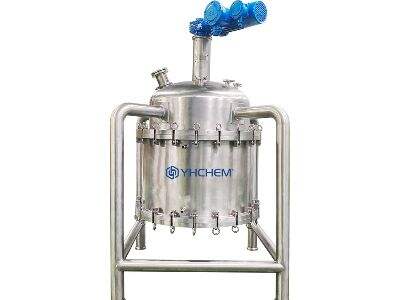

When selecting a stirred tank reactor there are a few things to consider. A stirred tank reactor is a large container in a factory that is used to mix liquids, gases, or solids. The right reactor can also enable better, faster products. There are various kinds of reactor, and each has its own unique applications. To find the best one, you should consider what it is made of (as in plastic or metal), how large it is, what kind of agitator it has and what its function takes. YHCHEM has stirred tank reactors that allow you to choose various options, so the one tends to work best for your whatever use case

Best New Boot Materials to Consider

When it comes to materials, the type can make a big difference in how the reactor operates. It doesn’t readily rust and can withstand high temperatures and pressure, this is why most stirred tank reactors are made of stainless steel. (However, if you are mixing something that is very corrosive, such as certain acids, then you may want to consider using materials like Hastelloy or glass-lined steel. Such materials may be chemically resistant. Now let’s say you are working with a product that has a lot of solids in it. You might require a reactor of special coating to prevent wear and tear. And don’t forget the temperature either. If your procedure runs hot, you need materials that can maintain their strength without breaking down. YHCHEM produces reactors in a variety of materials to accommodate these needs, allowing you to discover what’s best for your project. You may also want to consider its wall thickness. Thicker walls are better at resisting pressure, but they also make the reactor heavier and more difficult to move. While choosing, you need to balance weight and strength. So when selecting the material of your reactor, remember to always think about what kind of chemicals are being mixed and at what temperature and under what pressure

Where to Buy the Best Quality Stirred Tank Reactors at Wholesale Price

If you are in the market for stirred tank reactors YHCHEM is a good place to begin. We sell superior reactors at prices you'll love. You can order them directly from our website or reach out to one of our sales team to set up a consultation around your specific requirements. Additionally, purchasing in bulk can also save money, so if you’re working on a large project, consider ordering several reactors at one time. This is so you can cut a better deal. You can also customize your reactor by working with YHCHEM. We’re here to take the challenge and help you work out which size and style of reactor is just right for your process. You may also want to visit local industrial equipment suppliers. They sometimes have good deals, but compare prices and quality. Online marketplaces may also be of assistance, just look at the reviews to ensure you’re getting something reliable. Find firms that are reputable and have a customer service phone number. Note: Need to know when you purchase a stirred tank reactor, you are not just getting a piece of equipment; but rather an investment in your business. Selecting the correct reactor can make for more efficient production and a more profitable process

It’s very important to get everything right if you want to make chemicals or other products in stirred tank reactor

This involves a wise choice of materials, size and mixing tools. If you are able to get as much air as you want into a mass concrete or RCC, then your mix is OK. At YHCHEM, we understand that when you’re looking for the best in products there’s no room to wait – enter, our stirred tank reactor. First, a few words about improving what you are making. One way to accomplish this is by selecting the correct materials for your reactor. The material must not corrode and be strong enough to contain the chemicals within. Stainless steel is a popular option as it is resistant to rust. Secondly the volume of the reactor matters. If too small, you won’t be able to produce enough product. If it’s too big, your mixing may not be uniform, which can result in inconsistent products. The right size is key. Another thing that makes a big difference is the type of agitator to use. There are a variety of types of these agitators, such as propellers and turbine mixers. The Best One Can Help Mix the Ingredients Evenly and Make The Final Product More Smooth, Save Time. Lastly, also the process requirement needs to be considered-money(rm) in terms of temperature and pressure. Maintaining these conditions stable helps guarantee that reactions occur as they are supposed to, which leads to higher quality products. By paying attention to these areas, you can ensure that your stirred tank reactor gives a great performance - that’s what we strive for at YHCHEM

Some trends which are involved in shaping future of stirred tank reactor technology

SSH One big trend is the increasing use of sophisticated sensors. These sensors are able to track temperature, pressure and pH, among other things, in real time. That way, if something is amiss, you can make changes quickly. At YHCHEM, we believe rethinking technology in this way can lead to a better product. One trend, she noted, is the increasing attention to more sustainable methods. Lots of businesses are searching for methods to reduce waste and use less power. This implies the fact that stirred tank reactors are currently being developed to be more economical. You may hear about new models that consume less power yet still mix things up well. There's also a drive for automation across the board. Machines can control the operation of a reactor and dials on those machines would be easier than letting workers do it by hand. This can translate to fewer errors and higher quality products. Last but certainly not least, we need to remember the critical issue of safety. New designs are being developed to protect workers in stirred tank reactors. Protective design and better materials can help prevent them. There are also many other trends that will make people's life different in the future and all of them we must carefully observe; And here at YHCHEM we are glad we can join this change

Despite all of its benefits, stirred tank reactors do have their drawbacks, though. Another problem is that the mixing may not be homogeneous in all instances. If the substances are not well blended, then the end result may be uneven. To troubleshoot this issue, you can experiment with the speed of the agitator, or use a different type of mixer. Another challenge is temperature control. The chemical reactions in the reactor can get thrown off if the temperature gets too hot or too cold. You can solve this problem by stabilising the temperature, with the help of temperature sensors and cooling or heating jackets. Sometimes the materials can itself be problematic, such as material clogging or adhering to the walls of the reactor. This is why it’s important to pick the right materials and maintain your equipment. Moreover, safety is one of our concern in stirred tank reactors. And if it does not go well, it can be perilous. We always suggest you to follow the safety and protection rules: If you recognize these challenges and apply the correct solutions, then you can optimize your stirred tank reactor performance to produce products of high quality while minimising danger

Table of Contents

- Best New Boot Materials to Consider

- Where to Buy the Best Quality Stirred Tank Reactors at Wholesale Price

- It’s very important to get everything right if you want to make chemicals or other products in stirred tank reactor

- Some trends which are involved in shaping future of stirred tank reactor technology

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

UK

UK

HU

HU

TH

TH

TR

TR

GA

GA

BE

BE

BN

BN