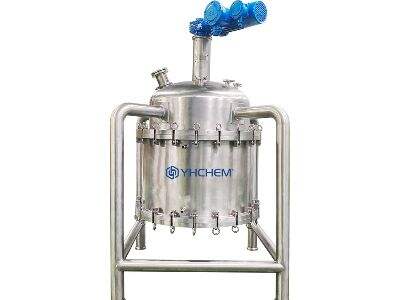

The effective stir tank reactor (STR) is centred on the agitator. The choice of the kind of impeller chosen is of a critical nature well known that determines the mixing efficiency, heat transfer, reaction yield and overall productivity directly. Being a major provider of integrated reactors YHCHEM is design oriented towards its Reactor Series starting with a full spectrum of agitator designs that have been developed to meet specific process needs in many industries including biopharmaceuticals, new energy and petrochemicals. To maximize operational performance it is important to understand the benefits and applications of each one of them.

Anchor and Paddle Agitators: Experts of Viscous Fluids.

The anchor and paddle agitators are ideal in mixing non-Newtonian and high viscosity fluids. The agitators are used very close to the vessel wall.

The individual agitators of the system are designed to conform to the shape of the tank that eliminates stagnation and fouling and promotes heat transfer via the jacket that is critical to processes that are temperature-sensitive like polymerizations or candy manufacturing. YHCHEM uses this design with viscous products in which homogenous bulk mixing and high heat exchange are necessary.

With their simple, flat blades, paddle agitators offer moderate shear and are also acceptable in blending low viscosity liquids or in keeping solids suspended. Their solid construction gives them a stable performance in simple applications of the mix in food manufacturing and electronics like adhesives. Where mild but effective mixing is of importance paddle agitators are used in YHCHEM.

Turbine Agitators: the All Round High-Performance Agitators.

One of the most common and general systems is the turbine agitators. They are designed with more than one blade that is placed radially along a central axis to produce high shear rates and radial fluid flow.

The main benefit of turbine agitators is that they can be used in the dispersion of gas bubbles and the production of good pumping power which is why they are applicable not only in gas-liquid dispersion applications namely fermentation or hydrogenation but also in the dispersion of liquids.

Turbine agitators are commonly employed in the Reactor Series at YHCHEM in highly exigent chemical syntheses within the petrochemical and progressive material manufacturing. The design facilitates high mass transfer and homogeneous mixing which are critical in providing equal product quality and scalable reactions. This is further complemented with YHCHEM built in Temperature Control systems to direct exothermic reactions.

Propeller Agitators: The Monarchs of the Axial Flow and Circulation.

Propeller agitators use the same concept as marine propellers only they provide a strong pattern of axial movement of fluid between the top and bottom of the system. This is an effective design that fits well in low to medium viscosity liquids.

Propeller agitators find application particularly in mixing incompatible liquids in preserving stable solid suspensions and in providing high circulation in high size tanks. Their low-shear, high-flow nature is good in their application where the gentle mixing requirement exists to avoid degradation or damage of the particles or cells.

YHCHEM uses propeller agitators in the work of the biopharmaceutical and environmental industries, e.g. in large fermentation broth larger Fermentation tanks or wastewater treatment vessels. They have a capability of developing constant and uniform circulation that provides uniform conditions in the vessel and this is crucial to process reliability and yield.

The Engine that best fits your Process: doesn’t the Right Agitator?

The choice of the right agitator is based on the characteristics of the fluid including its viscosity and density, process regulations (dispersing, suspending, heat transfer) and the intensity of shear that has to be achieved. One-size-fits-all does not exist.

The agitator types differ in their application depending on the amount of force needed to operate the system whether in a gentle movement like an anchor agitator or a powerful one like a turbine. The collaboration with the YHCHEM has more than 10,000 installed systems around the globe not only will you get an impeller but a highly designed piece of a high-performance integrated reactor system that is designed to make you successful in your industry.

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

UK

UK

HU

HU

TH

TH

TR

TR

GA

GA

BE

BE

BN

BN