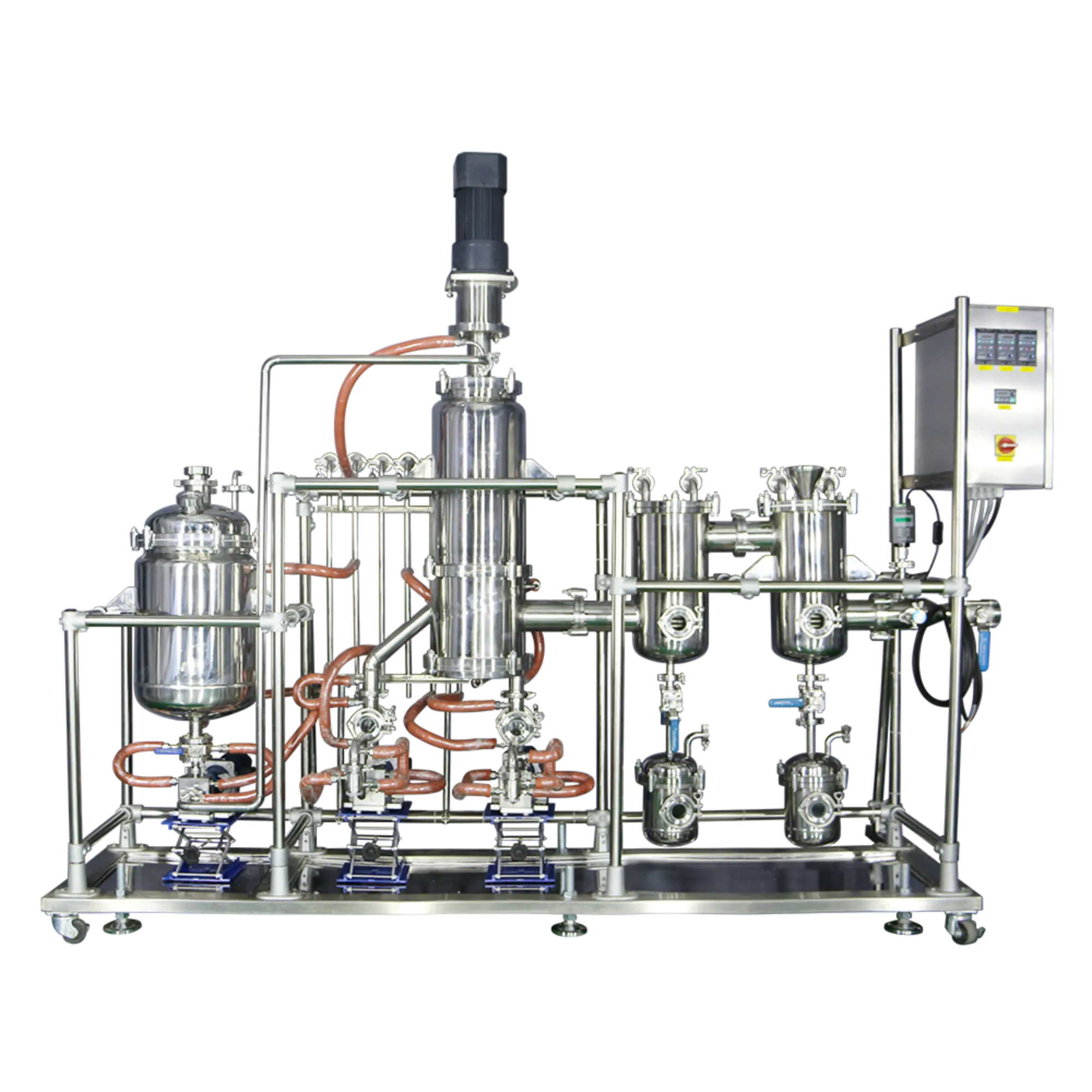

Stainless steel reactor is a kind of main machine which mainly plays the role of reaction kettle in many industries. Just as we want our toys to last, reactors also need a periodic going over to keep things running smoothly. YHCHEM, a top manufacturer of stainless steel reactors, provides guidance on maintaining these crucial machines. So what are the most effective methods for keeping reactors?

Crucial Service Aspects of Stainless Steel reactor:

Frequent Cleaning: In order to maintain your stainless steel reactors looks it is important that you clean it regularly. Wipe out any leftover material inside the reactor with a mild soap and water. Just be sure to rinse thoroughly to remove any soap.

Inspect Parts: Next, examine the reactor's various parts, such as the heating parts, gaskets, and seals, for signs of wear and tear. As soon as you see any broken part, go ahead and fix it in order to prevent leaks or issues during use.

Lubrication You’ll want to remember to grease all the moving parts inside the reactor. This enables them to function smoothly. Use the correct oil for each part so they operate well and for a long time.

Time Proven: Maintenance of Reactors:

Establish A Maintenance Schedule: Schedule when to inspect, and repair, your stainless steel reactor. Regular maintenance and inspections will help to keep it from breaking down and allow it to work as well as possible.

Record Keeping: Keep a record of your work to keep the reactor in shape such as repairs and inspecting. This will allow you to recall such work when you try to find any patterns or issues that repeatedly come up.

Train Staff: Ensure those who operate the reactor know how to care for it. Educating them with accurate information will keep everyone safe, and the reactor running smoothly.

Tunnel in Switzerland Signs Up for More Antiprotons:

Here are expert insights from YHCHEM, a reputed manufacturer of stainless steel reactors, about maintaining these machines.

Quality parts: When you must replace reactor parts, do so with quality pieces that complement stainless steel. This will prevent rust and keep the reactor alive longer.

Follow Directions: Be sure always to read the instructions that came with the reactor, so that you know how to deal with and operate it. Here are some tips for avoiding damage and ensuring good conditions.

Expert Advice:

YHCHEM specialists advise inspecting your stainless steel reactor closely at least once a month. This will enable you to catch any issues early and resolve them before they become more serious.

Best Practices for Reactor Maintenance:

Here are some procedures to help you maintain your stainless steel reactors in excellent condition:

Don't Overload: You do not want to overload the reactor. This can damage the machine and cause it to wear out quicker.

Watch the Temperature: Keep an eye on the temperature of the reactor and adjust if necessary to prevent it from overheating or cooling down to levels that can damage it.

Consult With Professionals: If you don’t know how to clean your stainless steel reactor, consult with professionals. They can manage tricky maintenance and keep things running properly.

In summary, your stainless steel reactor requires maintenance to maintain it in good condition. These tips from YHCHEM will help your reactor last longer and work its hardest. You know what they say, A well cleaned reactor, is a happy reactor!

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

UK

UK

HU

HU

TH

TH

TR

TR

GA

GA

BE

BE

BN

BN