Maximize Your Fluorination Efficiency with YMC-500 SiC Micro reactor Plugin from YHChem

In many industries, fluorination is used to replace any one of the halogens from a compound with fluorine atoms. This is a key step in the development of materials such as pharmaceuticals, Agrochemicals, Specialty chemicals. Nevertheless, fluorination is a difficult step since it usually needs harsh conditions for the reaction to take place. That is where the YHChem YMC-500 SiC Micro reactor comes in.

Introduction

We are entering a new era for the use of microprocessors in biocatalysts. It has been engineered for the reactants to come into contact with each other more effectively, leading to higher yields and less by-products.

High yield results with YMC-500 SiC Micro reactor for fluorination

Fluorination The high yield results in using the gear pump is one of the key advantages. The entire micro reactor works to make the fluorination process faster, which provides more of the beneficial product.

Used

Utilizing the YMC-500 SiC Micro reactor for high yield results, researchers and manufacturers are able to minimize waste and enhance their overall production costs. This is very critical in industries that has a high raw material cost, and slight improvement in yield can lead to huge savings.

Detail Technical Specifications of YHChem YMC-500

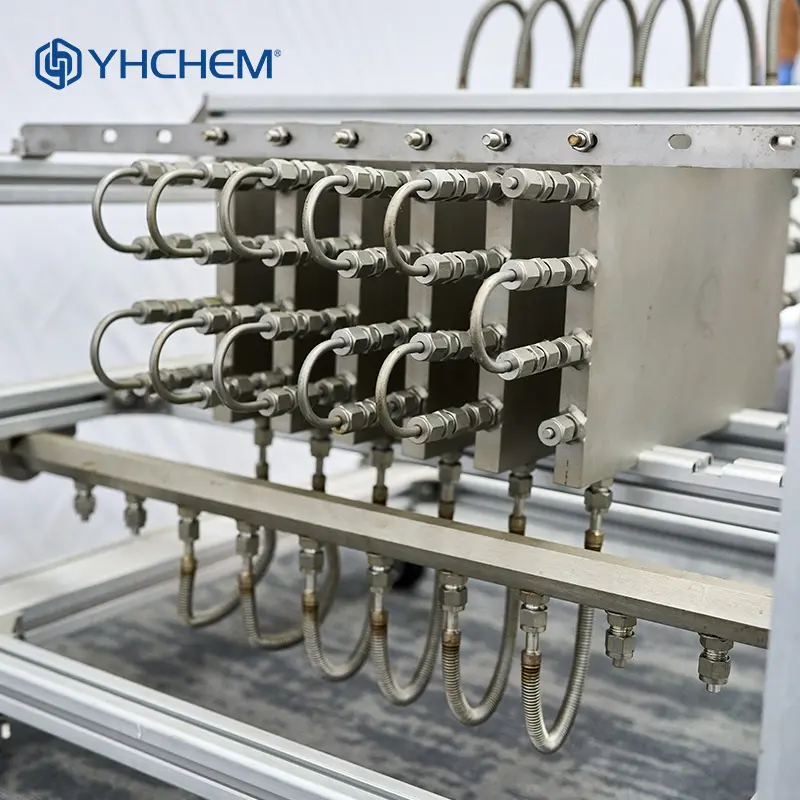

The corrosion resistance of the YMC-500 SiC Micro reactor from YHChem is one of the key improvements on traditional reactor systems. The micro reactor itself is constructed of silicon carbide, a material resistant to corrosion from harsh chemicals and capable of performing at high temperatures.

Enhancing Your Fluorination Process with the YMC-500 SiC Micro reactor

The approach of using forwarding dyes and photo-oxidation techniques has provided significant increases in solar cells efficiencies made from SiC Crystals. The distillation unitY offers a way to optimize the fluorination process by ensuring the reaction is done within a controlled environment. It is useful to control the temperature, pressure and mixing on micro reactor level which are factors that help to attain high yields and purity of product as possible.

Highly Efficient Fluorination with the YHChem YMC-500 SiC Micro reactor

The green micro reactor YHChem YMC-500 SiC is a new breakthrough in the field of fluorination technology, providing researchers and manufacturers a cost-effective yet prominent tool for high-yield reactions. A quantum leap embodied in the revolutionary concept design which enables a very good mixing of reactants, capability to control reaction conditions with high precision and a knock-out performance related to resistance against corrosion for all kind of industries using fluorination in their production processes.

Conclusion

The glass lab reactor is a process-changing technology that increases efficiency and product quality in fluorination. The micro reactor provides researchers and manufacturers the ability to produce products at higher yields, with less waste, and without product degradation than other competitive technologies for continuous processing in batch mode.

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

UK

UK

HU

HU

TH

TH

TR

TR

GA

GA

BE

BE

BN

BN