- PRODUCT DETAILS

- RELATED PRODUCTS

PRODUCT DETAILS

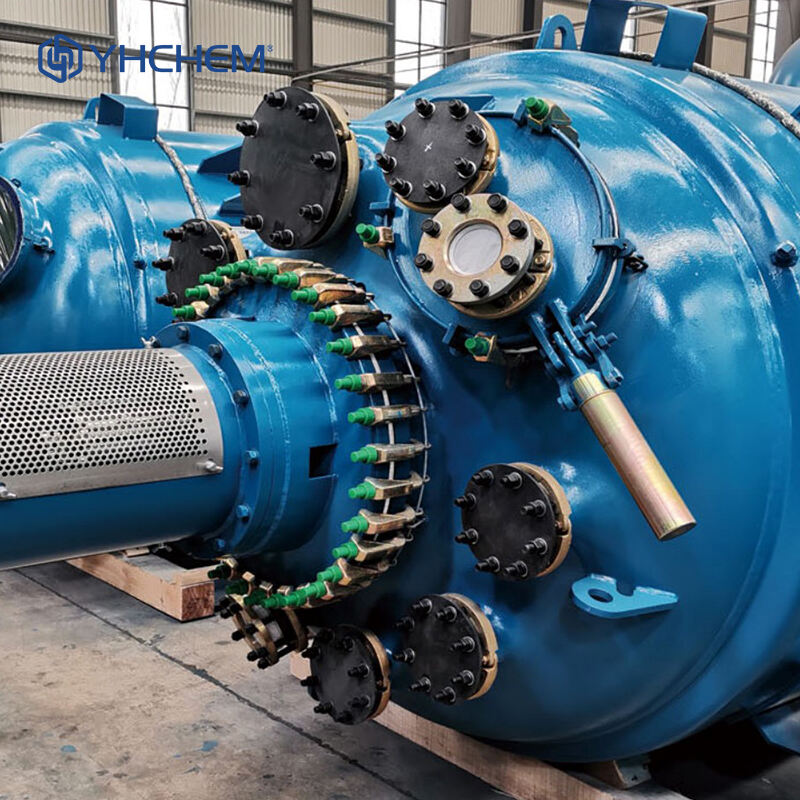

Overview

Glass-lined reactor is a corrosion-resistant equipment with the dual advantages of glass stability and metal strength. It is widely used in chemical, petroleum, medicine, pesticide, food and other industries. It is made of glass glaze with high silicon content sprayed on the surface of metal and fired at high temperature.

Features

● 1. Enamel material,Corrosion resistance

We mainly uses porcelain glaze material (porcelain glaze 1 #). It has excellent performance in terms of acid resistance, alkali resistance, corrosion resistance, mechanical impact resistance, temperature shock resistance and abrasion resistance. It can withstand most inorganic acids, organic acids, organic solvents, and weak bases, especially in media such as hydrochloric acid, nitric acid, aqua regia, etc. It has excellent corrosion resistance.

● 2. The normal temperature cold spraying and heat preservation slow firing technology

The glass-lined surface is smooth, non-stick to the medium and easy to clean.

● 3.Insulation,Isolation,Freshness preservation

Glass lining is suitable for situations where the medium is prone to generate static electricity during the production process.The glass layer isolates the medium from the metal, preventing iron ions from dissolving into the medium. Glass lining has excellent freshness preservation performance for the medium.

Typical Applications

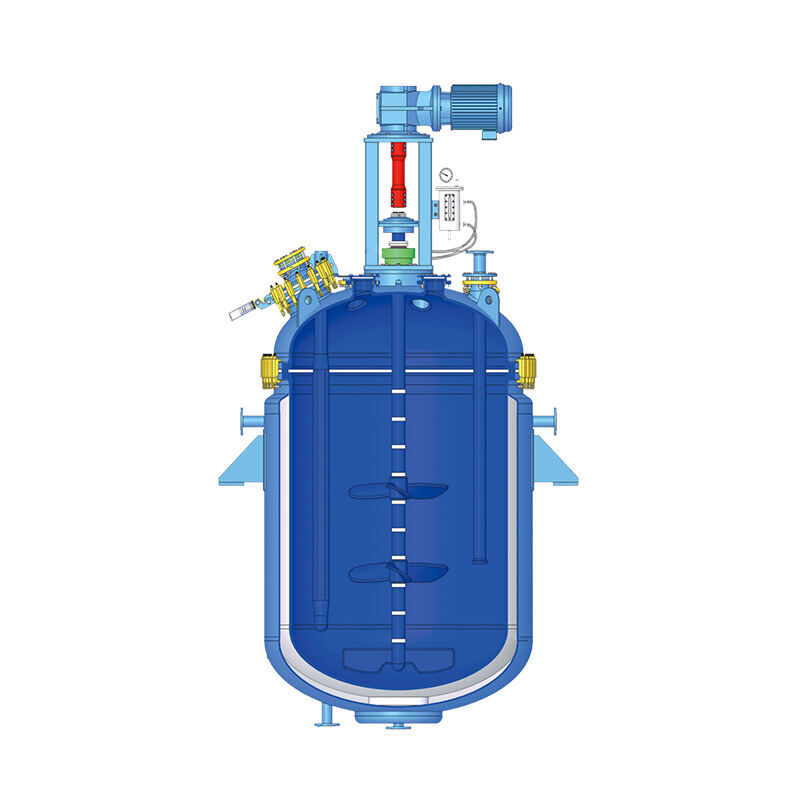

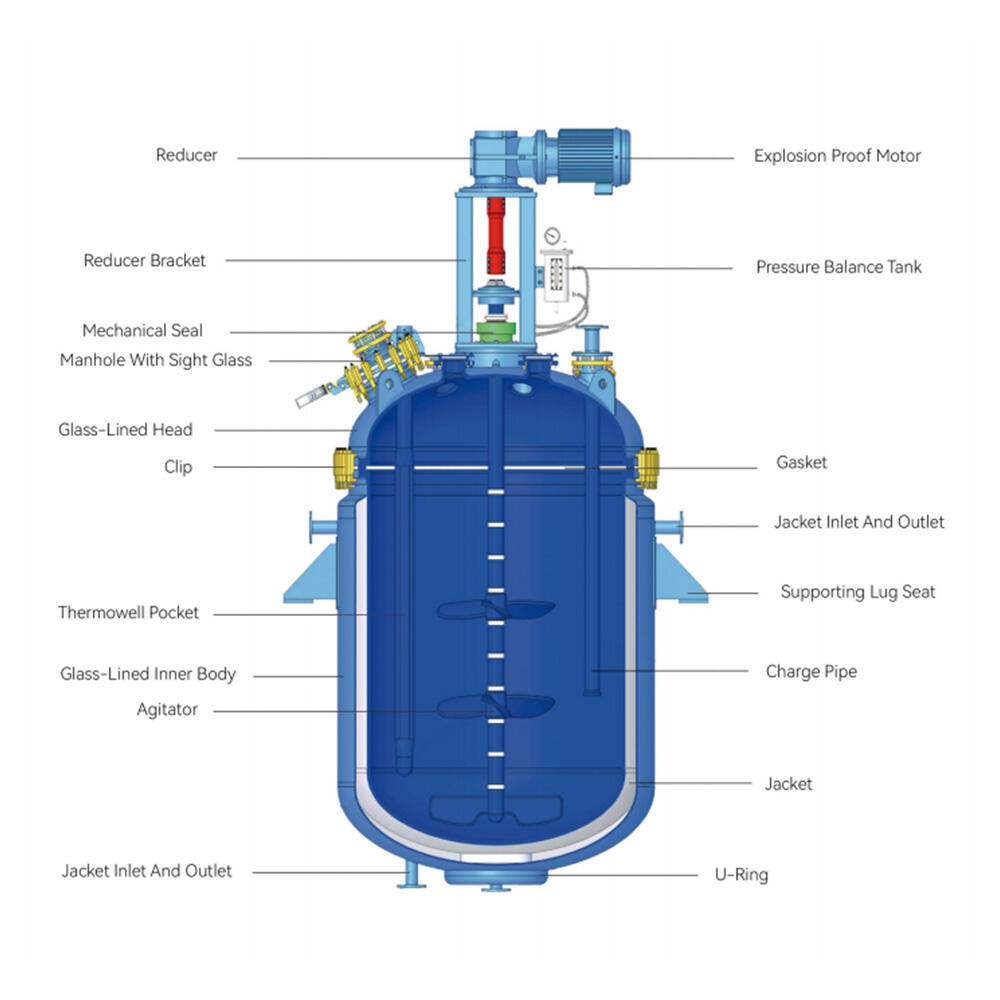

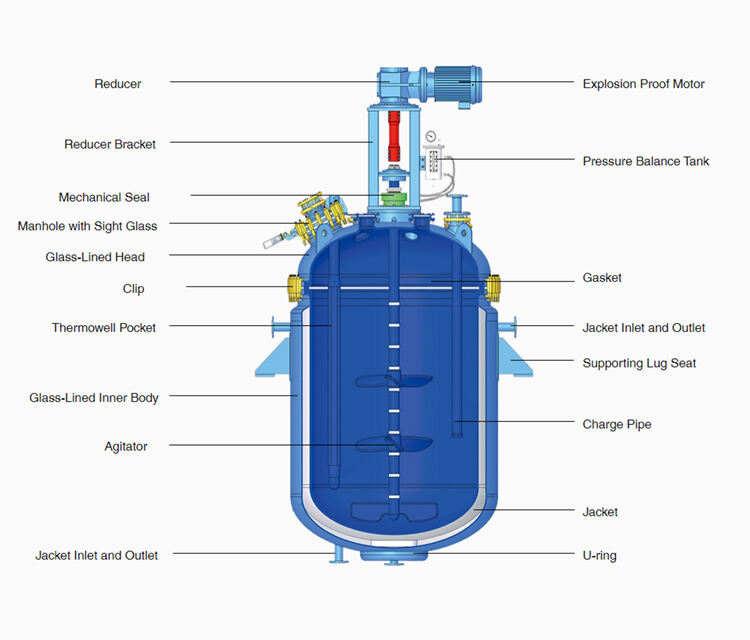

Product Structure

Product Parameter

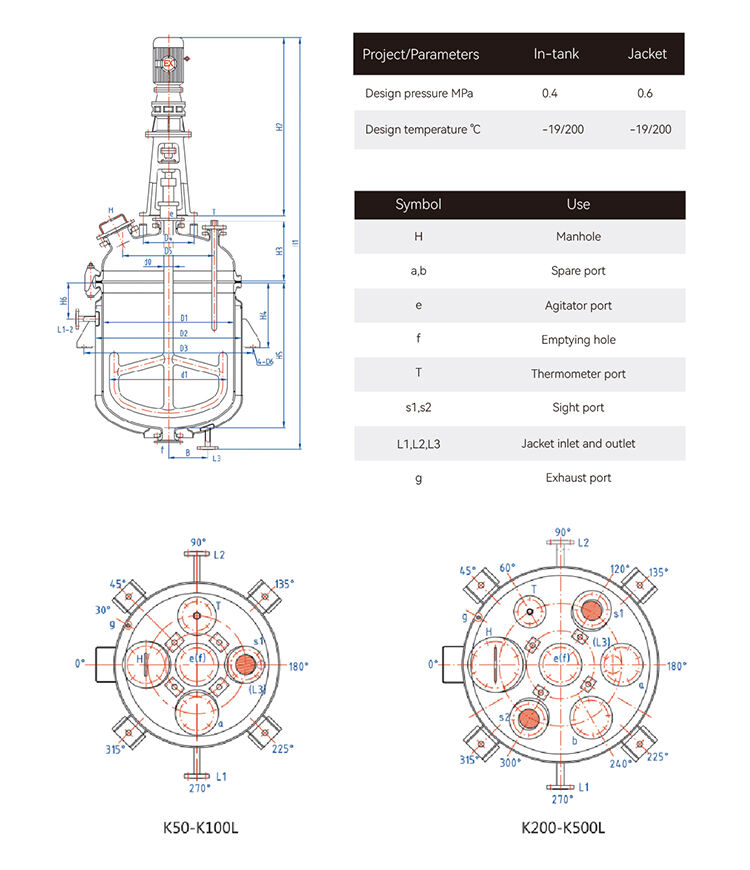

Open type glass-lined reactor (K type)

| Model | K50 | K100 | K200 | K300 | K500 |

| Full volume (m³) | 0.1 | 0.18 | 0.33 | 0.49 | 0.71 |

| Jacket volume (m³) | 0.022 | 0.035 | 0.067 | 0.077 | 0.12 |

| Heat exchange area (m²) | 0.58 | 0.9 | 1.5 | 2 | 2.67 |

| Internal surface area (m²) | 1.2 | 1.8 | 2.6 | 3.3 | 4.4 |

| Motor power(KW) | 0.55 | 0.75 | 1.1 | 1.5 | 2.2 |

| Weight (Kg) | 320 | 400 | 580 | 770 | 930 |

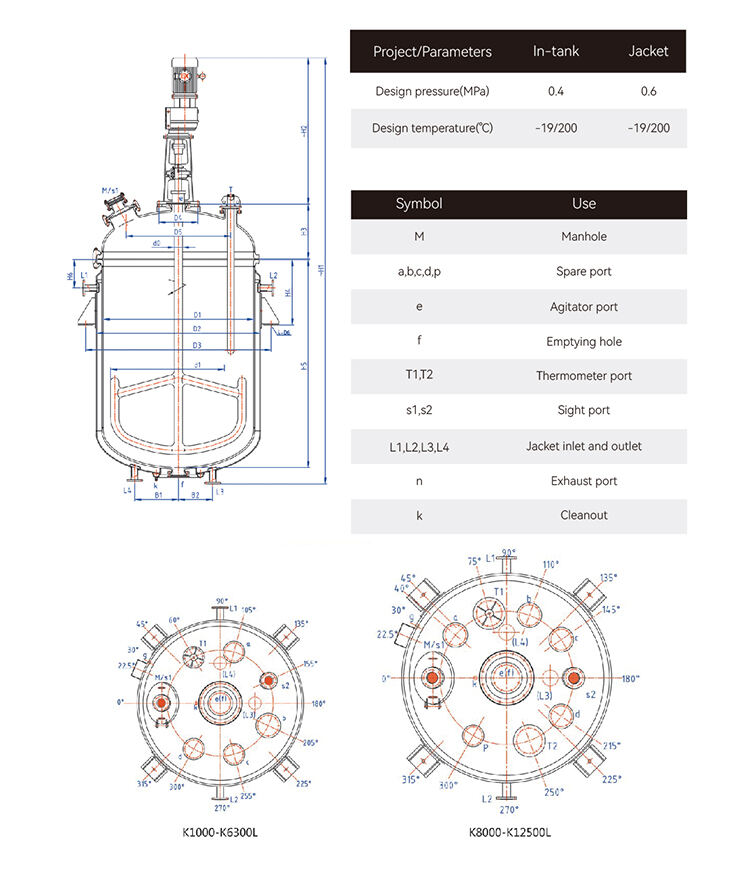

Open type glass-lined reactor (K type)

| Model | K1000 | K2000 | K3000 | K5000 | K6300 | K8000 | K10000 | K12500 |

| Full volume (m³) | 1.57 | 2.6 | 4.2 | 6.4 | 7.45 | 10 | 12.4 | 14 |

| Jacket volume (m³) | 0.22 | 0.47 | 0.6 | 0.8 | 0.95 | 1.55 | 1.8 | 2 |

| Heat exchange area (m²) | 4.53 | 7.2 | 9.3 | 13.4 | 15.9 | 18.8 | 21.2 | 24.3 |

| Internal surface area (m²) | 7.3 | 10.3 | 13.8 | 18.7 | 21.1 | 25.3 | 29 | 32 |

| Motor power(KW) | 4 | 4 | 5.5 | 7.5 | 11 | 11 | 15 | 15 |

| Weight (Kg) | 1670 | 2350 | 3470 | 4930 | 5620 | 7580 | 8530 | 9660 |

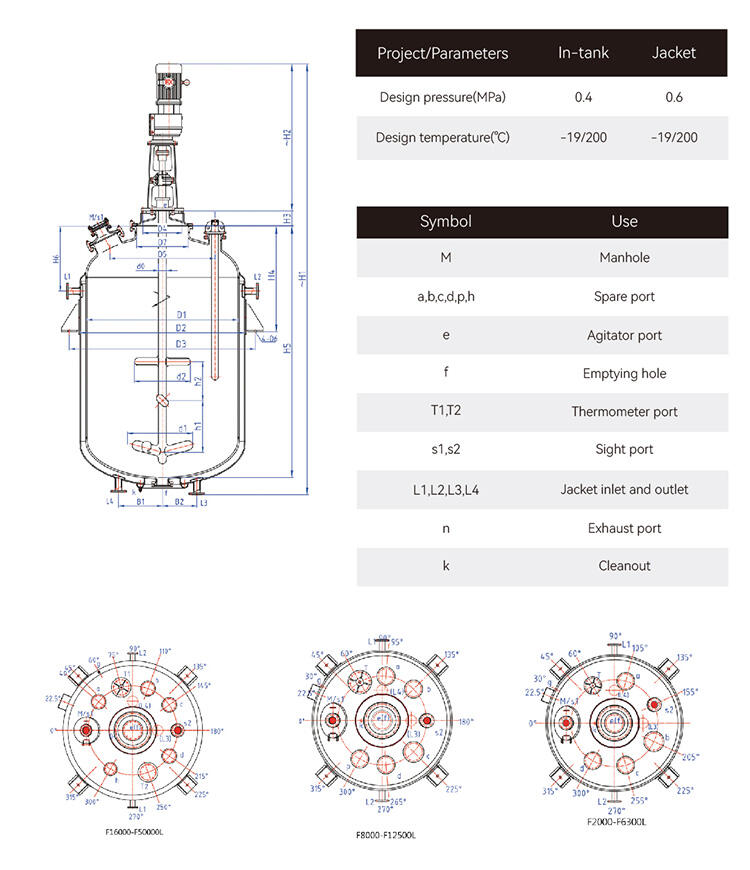

Open type glass-lined reactor (F type)

| Model | F2000 | F3000 | F5000 | F6300 | F8000 | F10000 | F12500 | F16000 | F20000 | F30000 | F50000 |

| Full volume (m³) | 2.4 | 3.85 | 6 | 6.82 | 9.04 | 11.65 | 13.6 | 17.28 | 21.7 | 34.3 | 56.6 |

| Jacket volume (m³) | 0.48 | 0.62 | 0.85 | 0.98 | 1.57 | 1.8 | 2.1 | 2.38 | 2.74 | 3.5 | 7.9 |

| Heat exchange area (m²) | 7.6 | 9.84 | 13.96 | 15.8 | 18.5 | 21.6 | 25.2 | 29.2 | 33.9 | 43.6 | 67.4 |

| Internal surface area (m²) | 9.75 | 12.95 | 17.76 | 20.05 | 24.16 | 27.66 | 31.6 | 35.66 | 41.58 | 56.48 | 79.5 |

| Motor power(KW) | 4 | 5.5 | 7.5 | 11 | 11 | 15 | 15 | 22 | 22 | 37 | 55 |

| Weight (Kg) | 2250 | 3220 | 4600 | 5130 | 7060 | 8040 | 9490 | 12570 | 14350 | 21980 | 35150 |

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

UK

UK

HU

HU

TH

TH

TR

TR

GA

GA

BE

BE

BN

BN