RE-530 Electric Rotary Evaporator Rotating Bottle Volume: 50L Temperature Range: RT~200℃

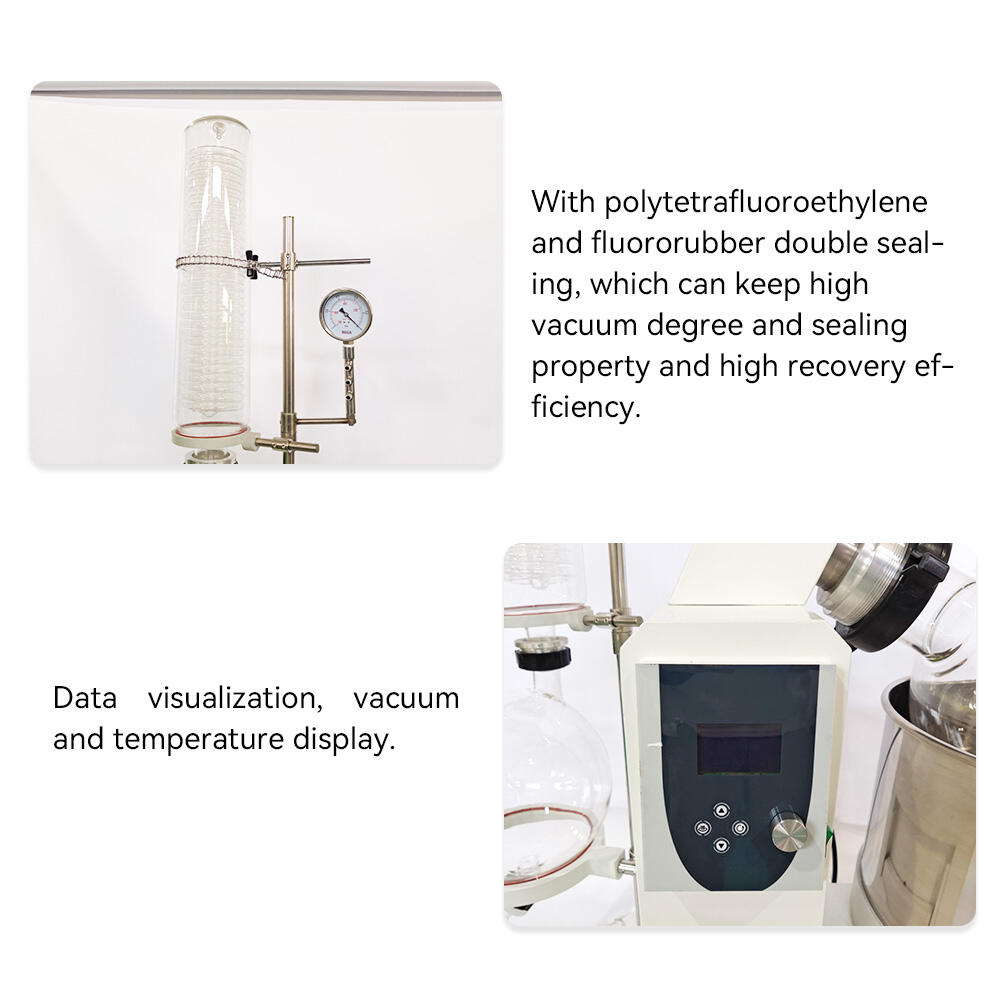

Large-area evaporation through rotary film formation under vacuum conditions. High borosilicate glass 3.3 is corrosion-resistant. PTFE+ fluororubber dual seal maintains high vacuum degree. PID precise temperature control RT-200℃. Automatic lifting operation is convenient. Complete specification series from 1 to 50L. Modular design for easy maintenance and upgrade. High-efficiency condenser ensures high recovery rate

- PRODUCT DETAILS

- RELATED PRODUCTS

PRODUCT DETAILS

Overview

The rotary evaporator is composed of a rotary motor, a distillation bottle, a heating pot, a condenser and other parts. It is also developed under the condition of vacuum negative pressure, constant temperature heating, and thin film evaporation. It is used for continuous distillation of volatile solvents under reduced pressure. Rotary evaporator is used in the scientific research and production process of medicine, chemical industry, biological products and other industries for evaporation, concentration, crystallization, drying, separation, solvent recovery and other equipment.

Features

● Rotary flash: Made of high borosilicate glass 3.3

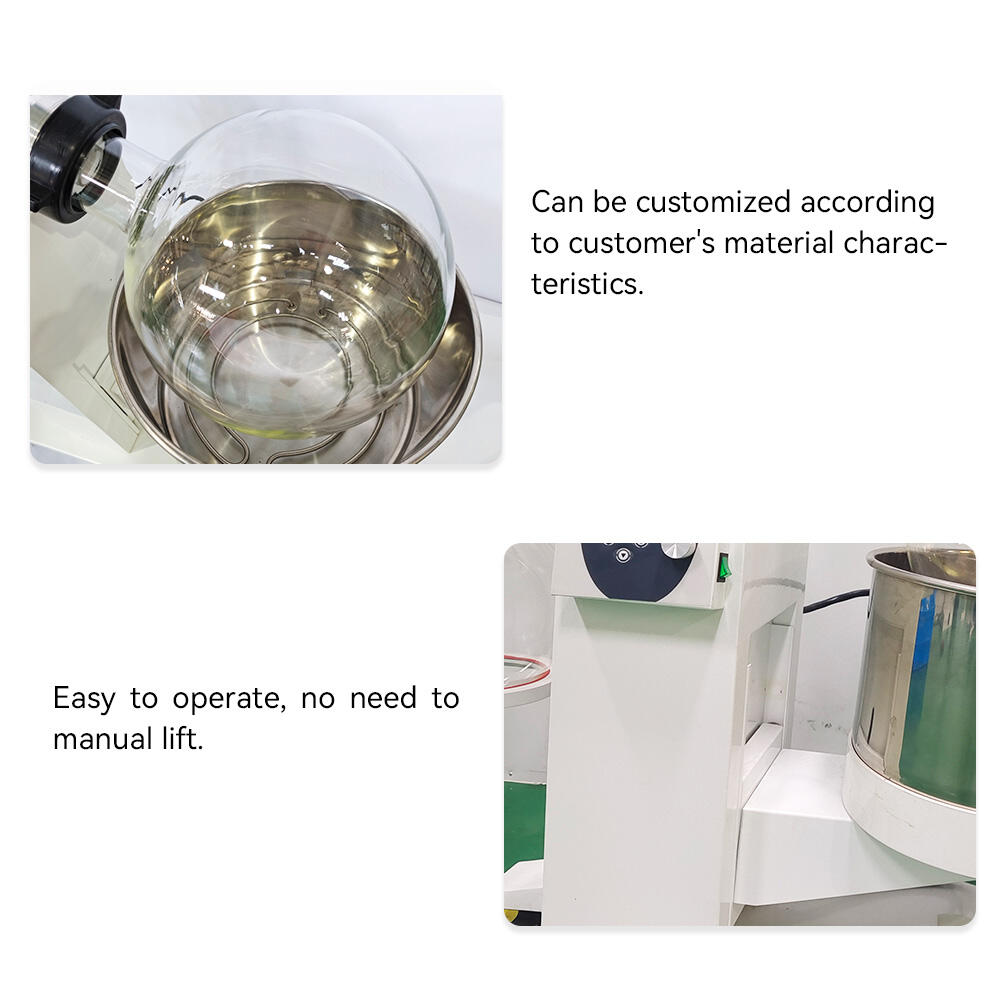

● Motor lift by one button: The heating bath can be lifted up and down electrically

● Two condensers design: Main condenser and vice condenser. Large condensation area and high recovery efficiency

● Digital controller: Data visualization, rotation speed and temperature display

● Optional upgrade to an explosion-proof version

● Motor lift by one button: The heating bath can be lifted up and down electrically

● Two condensers design: Main condenser and vice condenser. Large condensation area and high recovery efficiency

● Digital controller: Data visualization, rotation speed and temperature display

● Optional upgrade to an explosion-proof version

Typical Applications

Product Parameter

| Model | RE-501 | RE-502 | RE-505 | RE-510 | RE-520 | RE-530 | RE-550 |

| Evaporation Rate (Water L/h) | ≥1.2 | ≥1.2 | ≥2.2 | 0~3.2 | 0~5 | 0~7 | 0~9 |

| Rotary Bottle Volume (L) | 1 | 2 | 5 | 10 | 20 | 30 | 50 |

| Collection bottle volume (L) | 1 | 1 | 3 | 5 | 10 | 20 | 20 |

| Lifting stroke (mm) | 0-180 | ||||||

| Speed Range (rmp) | 20~120 rmp | ||||||

| Working temperature (°C) | RT-200 °C | ||||||

| Net weight of equipment (Kg) | 20 | 20 | 35 | 85 | 90 | 140 | 140 |

| Dimensions (cm) | 64*65*60 | 64*65*60 | 84*46*110 | 99*55*175 | 114*69*190 | 135*77*223 | 135*77*223 |

SUPPORTING EQUIPMENT

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

UK

UK

HU

HU

TH

TH

TR

TR

GA

GA

BE

BE

BN

BN