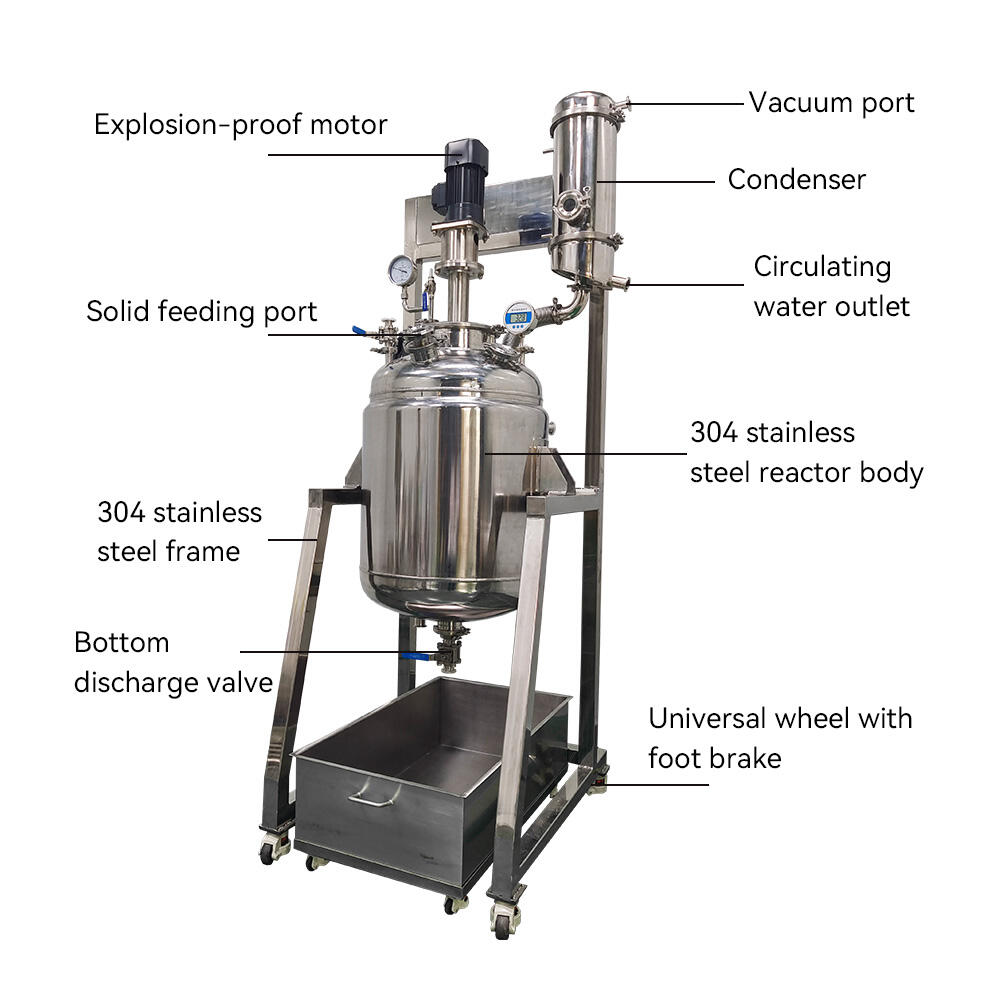

Single-Layer Stainless Steel Reactor Reactor Pressure: -0.1~0.1MPa

The core carrier of chemical reactions, ranging from 500mL laboratory models to 300L industrial models, multi-functional in one reactor, precise control. Compliant with GMP standards, efficiency is increased by 30%.

- PRODUCT DETAILS

- RELATED PRODUCTS

PRODUCT DETAILS

Overview

Stainless steel reactor is a chemical reaction vessel of stainless steel.It is composed of four parts:the inner vessel, jacket,stirring device,and supporting frame,participate in the completion of vulcanization,nitrification,hydrogenation,alkylation,polymerization,condensation and other processes,in order to participate in the intensive mixing of reactive substances as the premise,for heating,cooling,and liquid extraction and gas absorption and other physical changes using stirring device to achieve good results.It has the characteristics of rapid heating,high temperature resistance,corrosion resistance,health and easy to use.

We provide stainless steel reactors of various specifications, suitable for everything from laboratory experiments to industrial production. The product can be used with high and low temperature integrated machines, low temperature cooling circulation pumps, vacuum pumps, etc.

We provide stainless steel reactors of various specifications, suitable for everything from laboratory experiments to industrial production. The product can be used with high and low temperature integrated machines, low temperature cooling circulation pumps, vacuum pumps, etc.

Features

● SUS304 Fabrication

Corrosion Resistance, Wear Resistance, high temperature and high pressure resistance

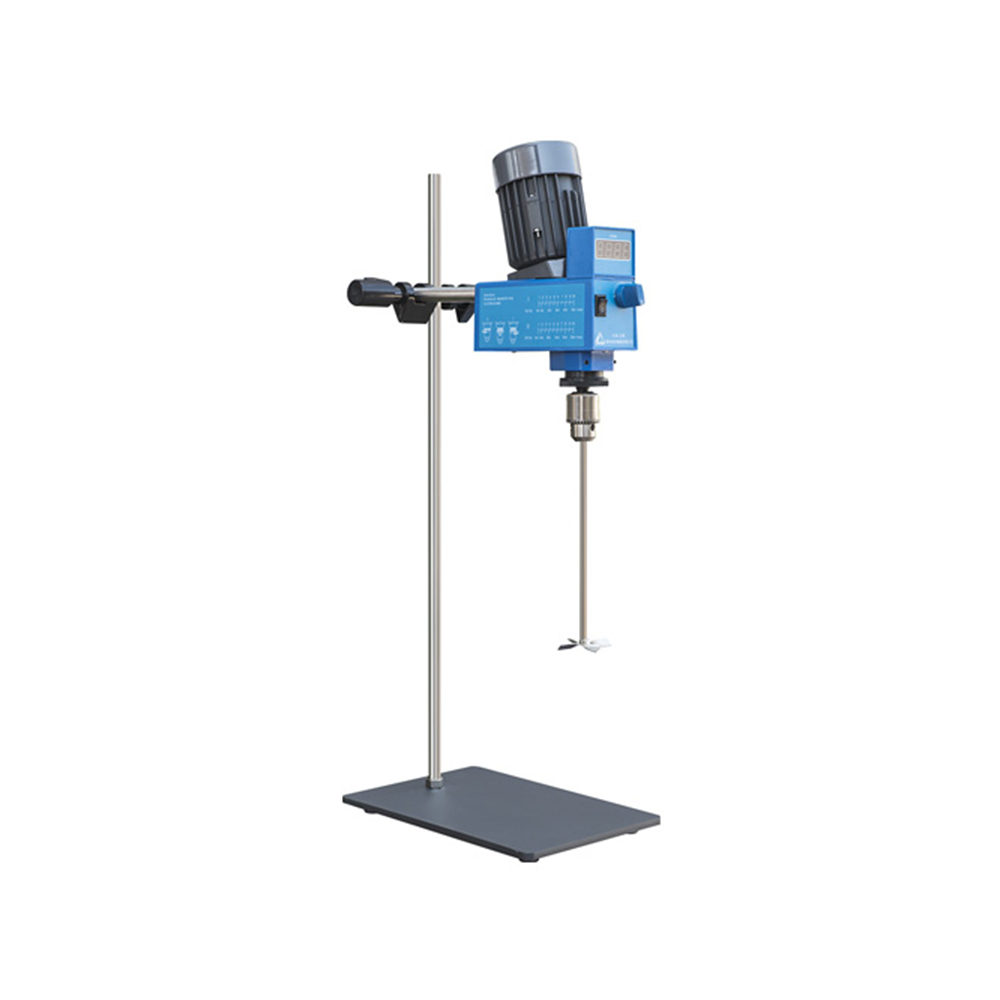

● Variable Frequency Speed Adjustment

● Variable Frequency Speed Adjustment

The stirring motor has the function of frequency conversion speed regulation, meeting the high and low speed requirement.

● Digital Display Speed Controller

● Digital Display Speed Controller

Automatic temperature control, Display speed, Stepless speed regulation

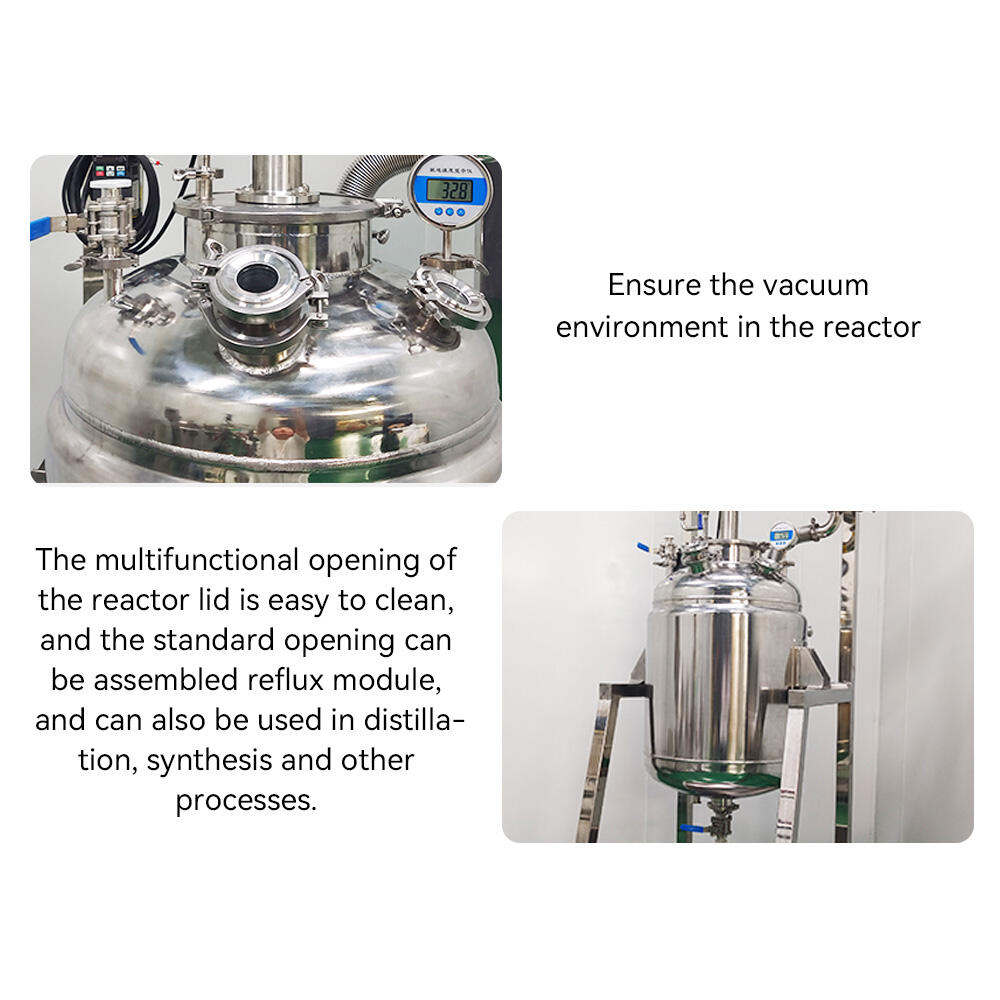

● Mechanical Seal

● Mechanical Seal

Ensure the vacuum environment in the reactor

● Convenient Function

● Convenient Function

The multifunctional opening of the reactor lid is easy to clean, and the standard opening can be assembled reflux module, and can also be used in distillation, synthesis and other processes.

Typical Applications

Petroleum, chemical industry, rubber, pesticide, dye, medicine, food

Product Parameter

| Model | JSR-10 | JSR-20 | JSR-30 | JSR-50 | JSR-100 | JSR-200 | JSR-300 |

| Net Volume(L) | 10 | 20 | 30 | 50 | 100 | 200 | 300 |

| Reflux Condenser-Heat Exchange Area (m²) | 0.2 | 0.3 | 0.5 | 1.0 | |||

| Material | S30408 | ||||||

| Sealing Form | Mechanical sealing | ||||||

| Stirring Motor (W) | 200 | 370 | 750 | ||||

| Speed range | 80~460 | 200~1000 | |||||

| Temperature In Kettle (℃) | -20~200 | ||||||

| Frame | SUS304 tube | ||||||

| Reactor Working Pressure (MPa) | -0.1~0.1 | ||||||

| Reflux Condenser-Material | S30408 | ||||||

| Power Supply | 220V1P | ||||||

| Weight(Kg) | 100 | 120 | 160 | 200 | 300 | 350 | 400 |

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

UK

UK

HU

HU

TH

TH

TR

TR

GA

GA

BE

BE

BN

BN