- PRODUCT DETAILS

- RELATED PRODUCTS

PRODUCT DETAILS

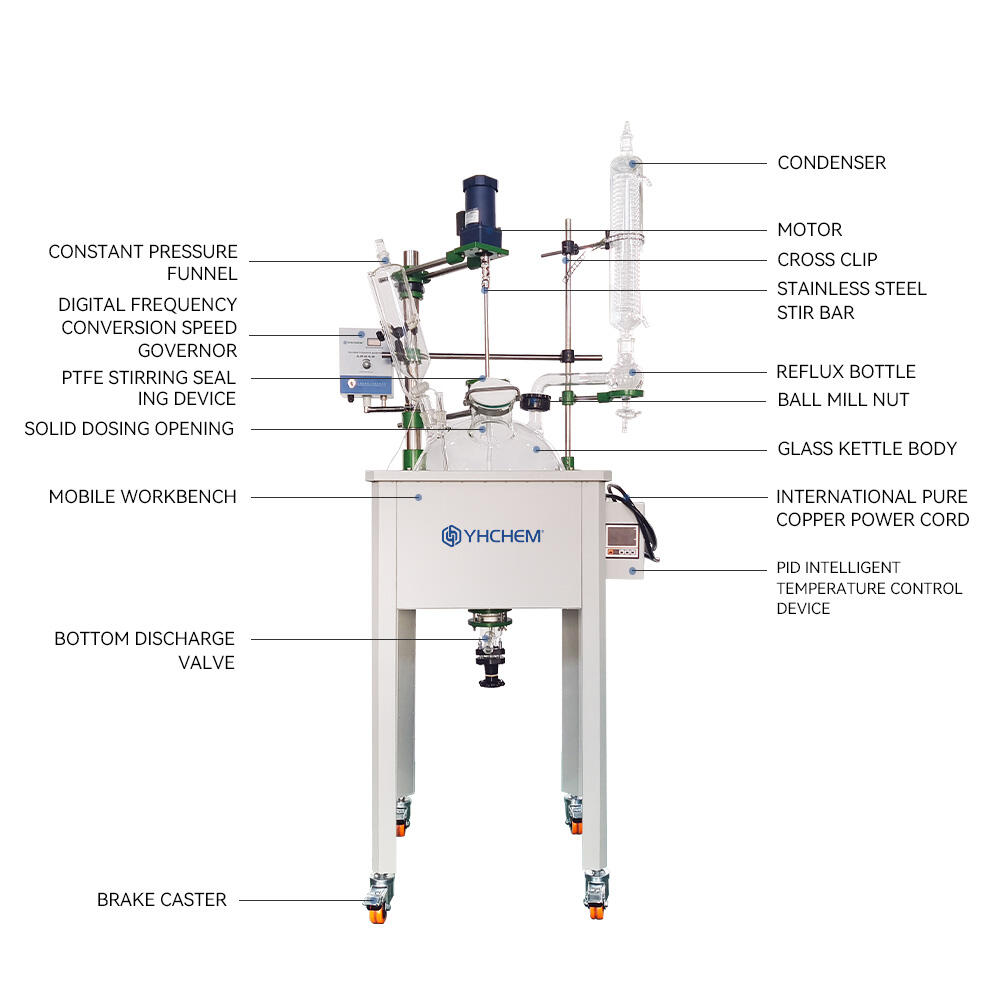

Overview

The single-layer glass reactor is the main equipment of the reaction device, and it is mainly a container that carries materials for chemical reactions. Through the structural design and parameter configuration of the container, the process requirements in the laboratory and industrial production are met. Glass single-layer reactors are widely used in petroleum, chemical, rubber, pesticide, dye, medicine and food and other fields.

Features

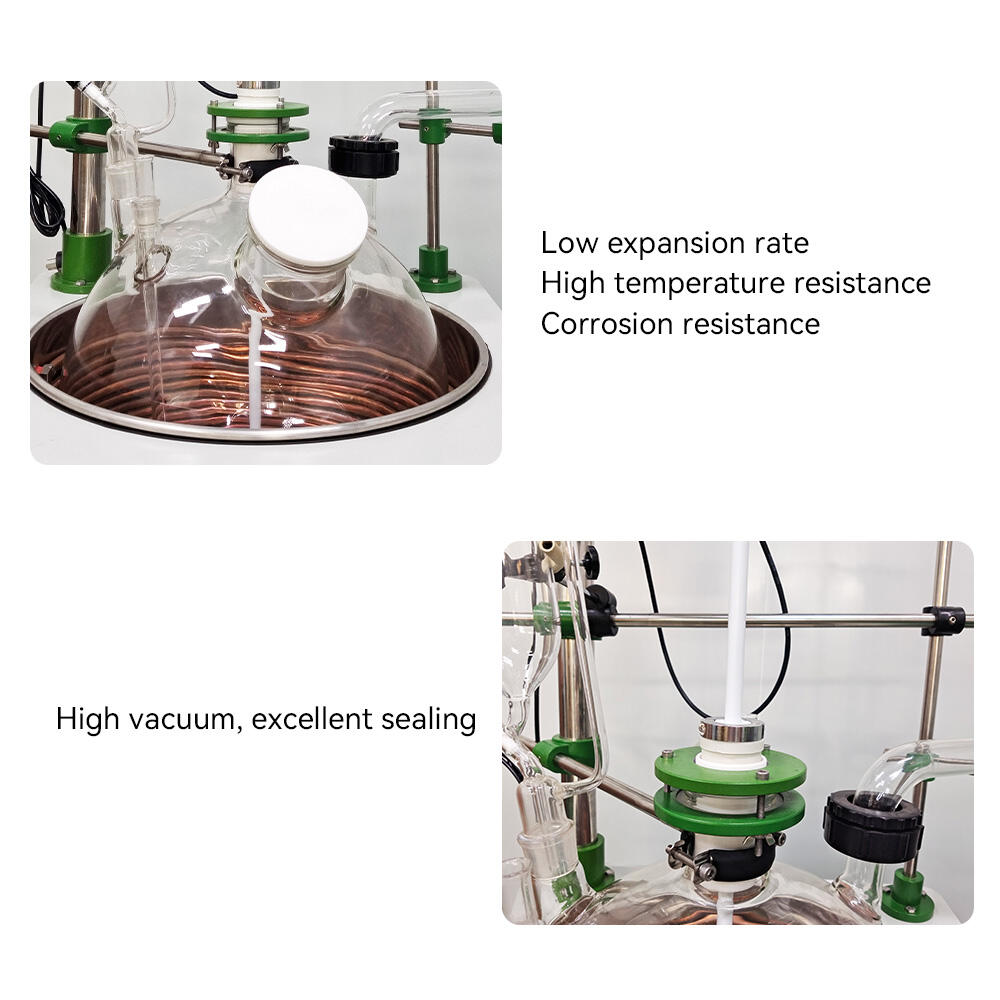

● High borosilicate glass 3.3

● Low expansion rate, high temperature resistance, corrosion resistance

● Fluorine rubber seal

● High vacuum, excellent sealing

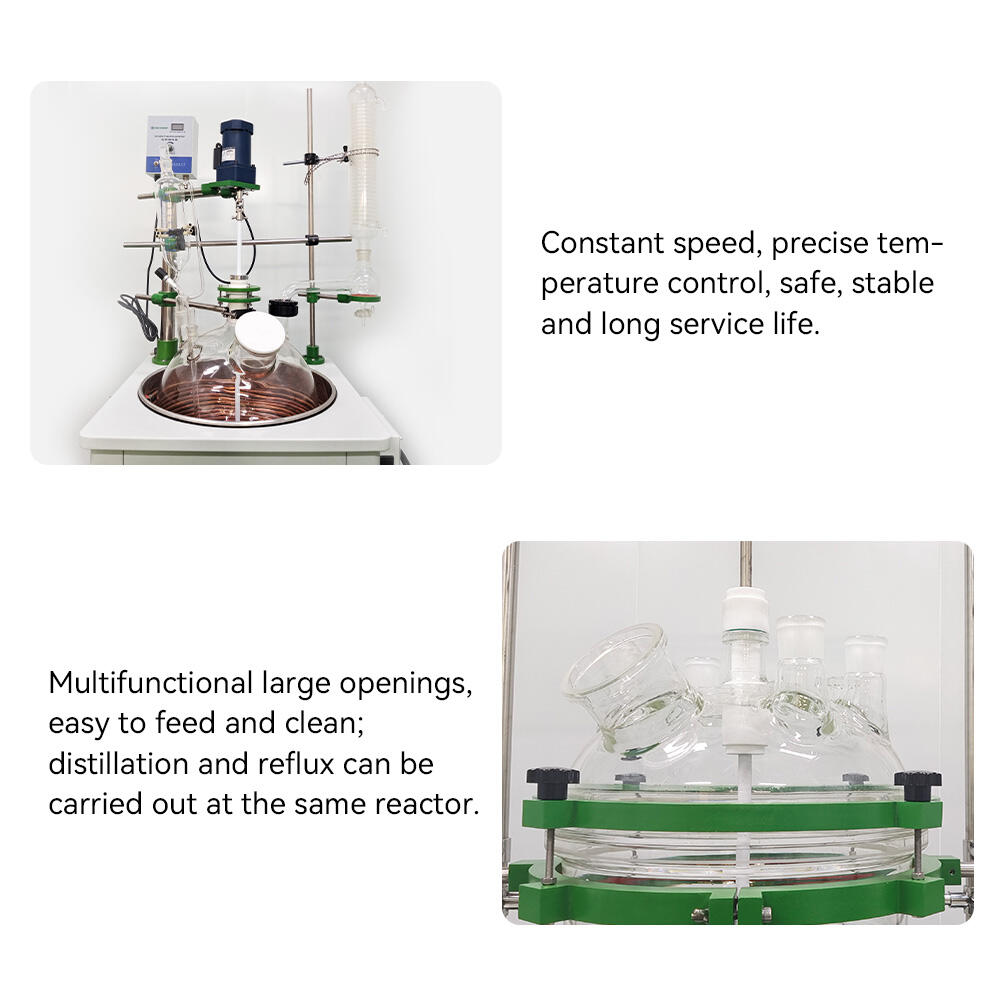

● Digital frequency conversion stepless speed control

● Constant speed, precise temperature control, safe, stable and long service life

● Convenient Operation

● Multifunctional large openings, easy to feed and clean; distillation and reflux can be carried out at the same reactor

● Low expansion rate, high temperature resistance, corrosion resistance

● Fluorine rubber seal

● High vacuum, excellent sealing

● Digital frequency conversion stepless speed control

● Constant speed, precise temperature control, safe, stable and long service life

● Convenient Operation

● Multifunctional large openings, easy to feed and clean; distillation and reflux can be carried out at the same reactor

Typical Applications

Petroleum, chemicals, rubber, pesticides, dyes, medicine and food

Product Parameter

| Model | SLR-10 | SLR-20 | SLR-30 | SLR-50 | SLR-100 | SLR-200 |

| Reactor Volume (L) | 10 | 20 | 30 | 50 | 100 | 200 |

| Condenser Heat Transfer Area (m²) | 0.3 | 0.4 | 0.6 | |||

| Dropping Funnel Volume (L) | 1 | 2 | ||||

| Receiving Flask Volume(L) | 0.5 | |||||

| Glass Material | high borosilicate 3.3 | |||||

| Frame Material | Cast iron | |||||

| Working Temperature Range (℃) | -80~200 | |||||

| Pressure In Kettle(Mpa) | -0.098 | |||||

| Motor Power (W) | 90 | 120 | 200 | 370 | ||

| Speed Control Mode | Frequency speed control | |||||

| Rotation Speed Range(rpm) | 0~1000 | 0~500 | ||||

| Heating Mode | Bath heating | |||||

| Power Supply | 220V/50Hz,1P | |||||

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

UK

UK

HU

HU

TH

TH

TR

TR

GA

GA

BE

BE

BN

BN