Making Solvents Safer with a Solvent Recovery System

Solvents - Solvents are in dustry mateials that the business uses as cleaning agents and other applications which may be hazardous. One solution to this problem is equipment that has been specifically engineered for the process, solvent distillation units saved_issue1. These systems are clearly a significant progress as we strive to safely and efficiently utilize solvents. Why this gear is so helpful and why you should care.

One of the main benefits to using solvent distillation units is how much better they clean than standard process in place (CIP) tanks. In addition to improving the cleanup process, these units provide environmentally-friendly solutions as well as time-saving features and the ability to capture up to 98% of solvents. With less waste produced, the minimal water input results in substantial cost savings; truly creating a win/win scenario for businesses considering capital expenditure.

Advantages of Using Solvent Distillation Machines

Solvent distillation units are another way to decontaminate solvents and reduce waste by recycling as much as 98% of spun-out chemicals. This way, the reduced ecological footprint also saves businesses substantial money. Companies that reuse solvents smartly will help reduce disposal costs and associated environmental woes, while creating a better work environment by applying green practices.

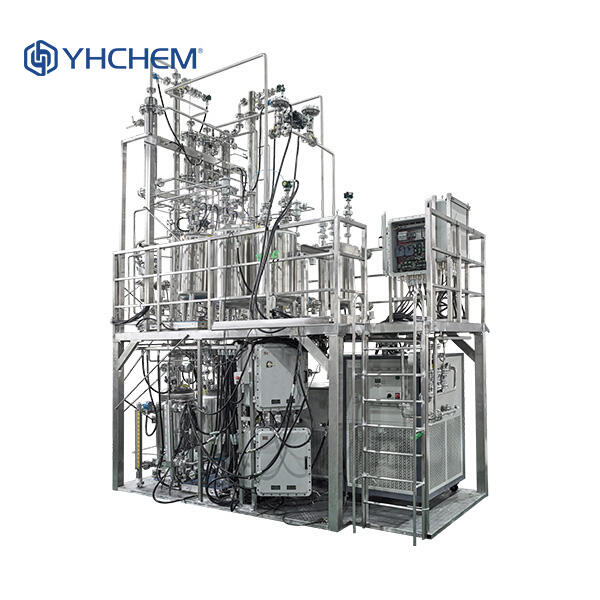

The solvent distillation equipment incorporates the finest engineering when it comes to regular & safe modes of operation in solvents recovery processes. These units will also make use of advanced technology inoperating smartly and thus consuming less energy which can be good for the environment too. This equipment has evolved allowing for increasingly better solvent recovery rates, higher than traditional methods and incorporating new technology to achieve the best results. Moreover, using energyefficient cooling protocols furthers the advantages of this equipment and encourages responsible consumption leading to savings in cost as well as environment conservation.

Security regulations syndicated in Solvent Distillation

Worker safety must be taken as a prime concern while dealing with solvent distillation equipment. However, with these units, the bulk of safety risks that traditional solvents may entail such as irritation or nausea can be mitigated. The risk of fires or explosions is greatly minimized by the use of controlled distillation processes where solvents are not allowed to rise above flash point temperatures. This is part having a pro-active attitude which benefits people's health, but also from creating safe working environments so that employees feel confident.

Solvent distillation equipment can be operated with ease and does not need special training. To keep these machines functioning as well and safely like they should the time required for regular cleaning going by safety measures is important too. If users follow the manufacturer instructions properly there is no need to guarantee them personally, and they can get devices working efficiently without any hassle.

The same is true for solvent distillation equipment, with the manufacturers providing ongoing customer service for repair and maintenance as well as a comprehensive list of available services like solvent recovery. This type of support enables businesses to tackle any issues right away and holds the equipment's full potential. Certain suppliers will even service these solvents, collecting used solvent for re-use at a cost. This service improves not only operational efficiency but also helps in cost saving and gives environmental benefits too.

Quality and Longevity Is..." -.

Precision engineering in solvent distillation equipment provides unbeatable quality and longevity - a sound investment. These units are precision engineered with a sturdy design that is constructed not only to be used repetitively within vigorous industrial environments, but also for high-end performance throughout. Every component is designed for smooth operation to radiate towards optimal performance and long lifetime required by the businesses who demands trouble-free solvent recovery solutions.

We've provided Solvent distillation equipment thousands well-known companies in than 100 countries, earning wide acceptance trust. Based on the needs of our customers' demands, we continually improve our products services. We're committed to increasing value and returns for our clients.

As a company has been listed Solvent distillation equipment have a stable financial stability and sustainable development capabilities. will continue to adhere to principles that are based market demand, driving continuous product innovation technological advances to create more value and opportunities for investors, customers, and employees.

We offer a wide range products, including Solvent distillation equipment, temperature control, distillation reaction instruments. Our product range is made to meet the demands different industries. We provide our customers an all-in-one service that includes multiple service supply centers, providing customers prompt technical support well as after-sales support products.

We are a global leader technological innovation, R and D and technology upgrades. We constantly introducing new technologies from around world while developing independent innovations and technological advancements. We have set up joint laboratories in conjunction with research institutes such as Shanghai Chemical Industry Research Institute East China University of Science and Technology. These labs have been established provide Solvent distillation equipment with the most competitive solutions and products.

Solvent distillation equipment includes many features for different industries with respect to saving money, recycling solvents and environmental friendly. Especially in solvent-intensive industries like, pharmaceuticals companies(Automotive / Coating etc) where this equipment can make processes faster and efficient that leads to cost reduction as well promotes green movement. Businesses can expect to transform their solvent management practices and achieve environmental stewardship success by adding solvent distillation equipment.