Thin film distillation is a unique process used to produce extremely pure oils and chemicals. It is sold in a specialized machine that heats the liquid and turns it into a vapor. The vapor then cools and condenses back into a liquid. In doing so, it leaves dust and other yucky stuff behind, and leaves the liquid clean and pure. Here’s a deeper dive into how Glass Thin Film evaporator works, and why it matters.

In thin film distillation, the liquid is spread out in a thin film along the inside of a rotating tube. This tube heats up and the liquid begins to evaporate. The vapor chills and transforms back into a liquid as it snakes through the tube. The mud is left, only the pure liquid flows through at the end. This technology is neat because it can borough things super pure in a single swoop.

The distillation of thin films of liquid works because different things boil at different temperatures. As that liquid heats, the components that vaporize at lower temperatures vaporize first. This steam is then condensed and cooled to obtain the pure liquid. With this technique, thin film evaporation can be used to divide mixtures of substances and distill them so purely.

Advantages of Thin Film Distillation Transfer of the volatile substances takes place in single stage Low holdup of the heated membranes Low residence time Small heating surface necessary Compact design Simple system design Easy to clean Competitive process economics Medium vacuum operation requires little energy.

It is the widely used across various industries for Stainless Steel Thin Film evaporator as it offers numerous benefits. It can also purify oils, chemicals and other ingredients used to produce medicines, foods and every day products. Thin film distillation removes impurities and contaminants to ensure raw and unfinished products are cleaner and safe for all users. It is also an effective way of reducing time and cost of purification.

Thin film distillation for the separation of various chemicals from mixtures and the like. This is extremely important because there are chemicals that are dangerous if they are not pure. Thin film distillation lets companies ensure that their products are pure and safe. With equipment and high-quality work gloves, they can also conserve materials and reuse precious chemicals.

Thin film distillation is a game changer, because it can make things purer, faster. With the help of a thin layer of liquid and a spinning tube, it can isolate substances better than the prior approach. That means companies could make purer products in less time, saving energy and resources.

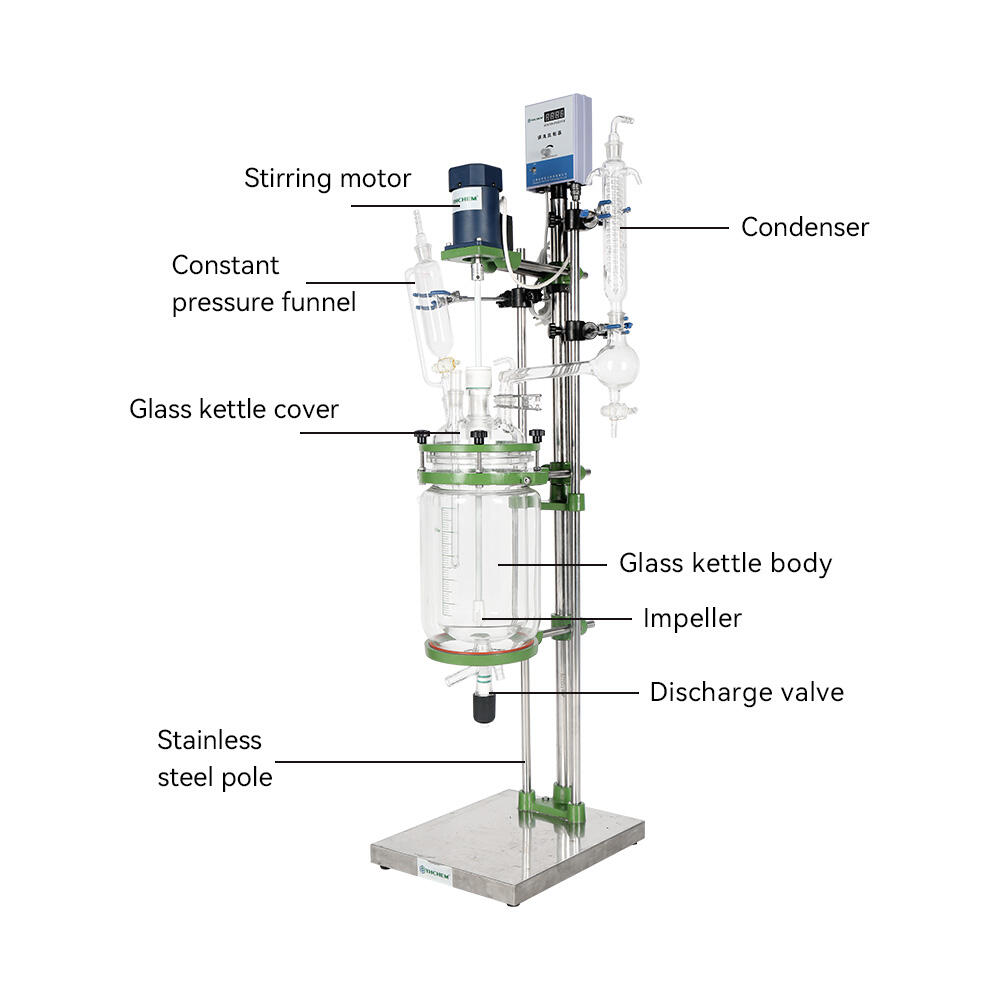

We provide a range of products include glassware, thin film distillation control, distillation reaction instruments. Our product line is specifically designed to meet the needs different industries. With a variety of service supply stations, we offer customers scientific all-in-one products services that provide prompt technical support as well after-sales services throughout their use.

We have strong financial foundation a long-lasting capacity for development a publicly traded company. We will continue to adhere market demand-oriented principles, driving continuous thin film distillation innovation technological advances to create more value and opportunities for customers, investors and employees.

We are a global leader technological innovation, R and D and technology upgrades. We constantly introducing new technologies from around world while developing independent innovations and technological advancements. We have set up joint laboratories in conjunction with research institutes such as Shanghai Chemical Industry Research Institute East China University of Science and Technology. These labs have been established provide thin film distillation with the most competitive solutions and products.

Our products have assisted thousands of well-known businesses in more than 100 countries as well as regions throughout the world, gaining thin film distillation recognition and trust. We are committed to enhancing our products and services according to the feedback of our customers.