- PRODUCT DETAILS

- RELATED PRODUCTS

PRODUCT DETAILS

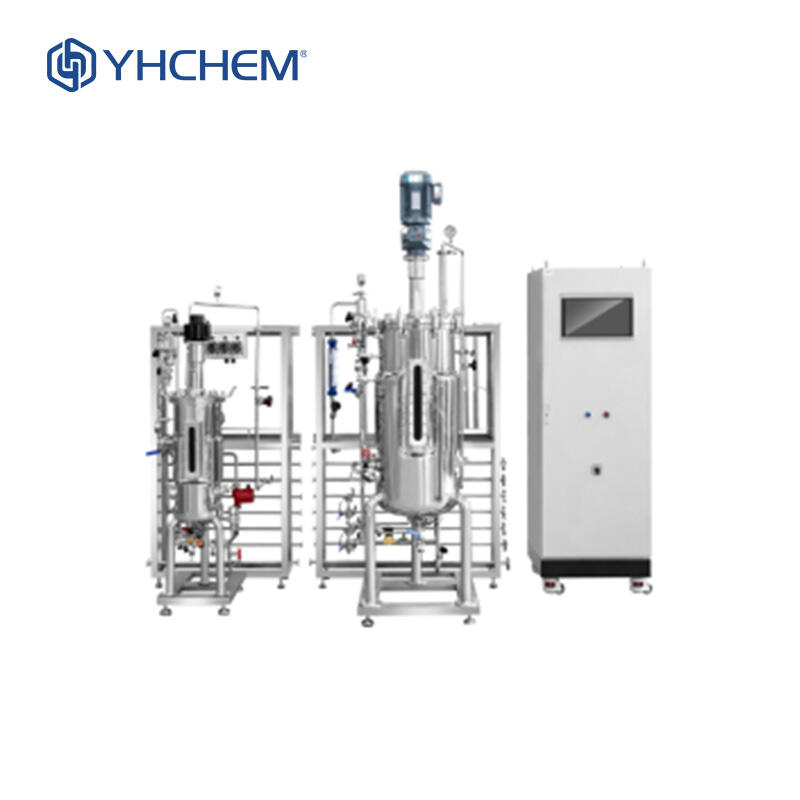

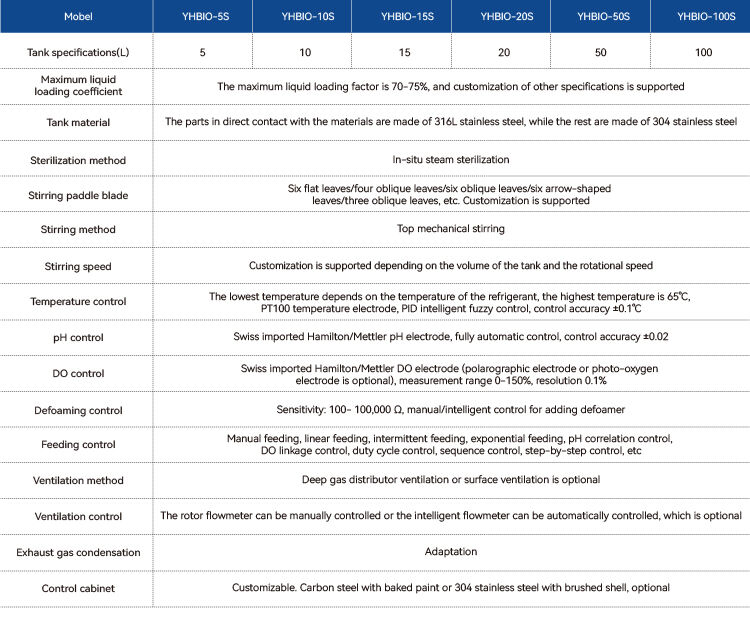

Overview

It is mainly made of SUS304/316L stainless steel, featuring high strength and resistance to high-pressure sterilization. The capacity ranges from 50L to several cubic meters.It is suitable for the expansion and cultivation of microbial strains, pharmaceutical intermediates, food additives, enzyme preparations, raw materials, etc. Compared with glass products, it is more suitable for large-scale fermentation (such as antibiotic and vaccine production) and high-density cultivation. It can be made into a larger volume, has better pressure and temperature resistance, is universal for water, electricity and gas pipelines, and can be expanded with more functions. It can meet cGMP standards.

Advantages

● High strength and industrial grade design

Made of SUS304/316L stainless steel, it is resistant to high-pressure sterilization (SIP) and strong acid and strong alkali environments, meeting GMP production standards.

The tank body is mirror-polished and equipped with an integrated CIP online cleaning system to reduce the risk of contamination.

● Support multi-link parallel design

Multiple sets of parameter comparison tests can be conducted simultaneously, shortening the process development cycle

● Various types of stirring paddles

Microbial or cell cultures adapted to different shear force requirements

● The mechanical stirring (top-mounted /) is suitable for a wide speed range of 20-1000rpm, and the shearing force is controllable.

The data management system stores over 1,000 batches of fermentation parameters and supports process traceability and optimization analysis.

● A variety of customized services

multi-parameter online monitoring, feed weighing, glucose/lactic acid online analyzer, Biomass online prediction, exhaust gas O2/CO2 online detection, (ethyl) alcohol content online detection, buglab cell concentration monitor, biomass module, etc

● Integrate temperature, pH, dissolved oxygen sensors and PID algorithm

The dissolved oxygen regulation range is 0-200%

● Support strategies such as pH-DO joint control feeding and index feeding

Optimize the efficiency of metabolite synthesis

● Parallelism software design

Before the Experiment: DOE (Design of Experiment)

In the experiment: Parallel control of the main software and remote monitoring software

After the experiment: Data management and processing software (QBD-oriented)

Application field

Dairy products, beverages, bioengineering, pharmaceuticals, fine chemicals, scientific research and educational institutions

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

UK

UK

HU

HU

TH

TH

TR

TR

GA

GA

BE

BE

BN

BN