Customised Stainless Steel Rectifying Column

It is made of high borosilicate 3.3 glass corrosion-resistant material or 316L stainless steel material. The volume and tower height can be flexibly customized. It can withstand a maximum temperature of 300°C and an ultimate vacuum of ≤0.098Pa. It is widely used in laboratories and chemical production for efficient gas-liquid mass transfer separation. The equipment can be modularized and combined to meet the needs of multiple scenarios such as fine chemicals and pharmaceuticals.

- PRODUCT DETAILS

- RELATED PRODUCTS

PRODUCT DETAILS

Overview

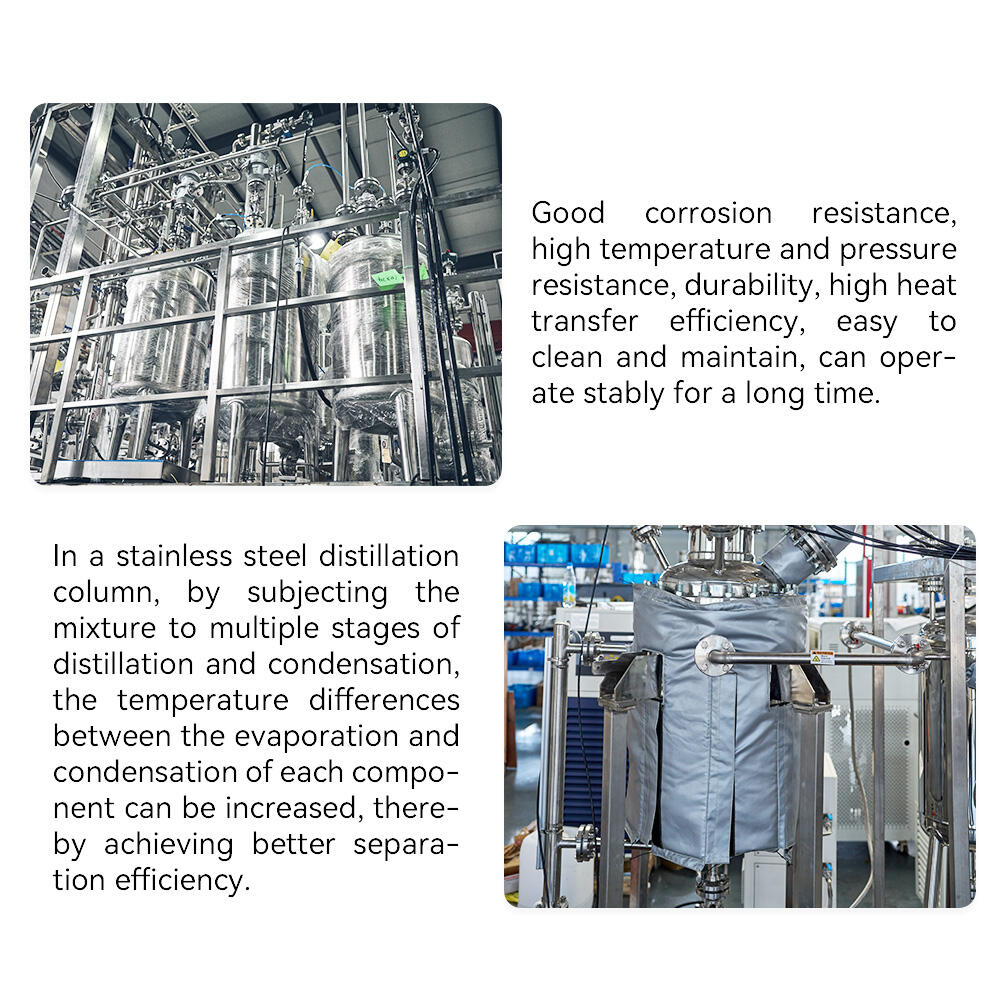

The small and medium-sized test equipment is made of stainless steel and can be designed for normal, reduced and pressurized use. The tower kettle can be designed with electric heating, thermal oil, steam and other heating methods. The specifications of the tower sections can be customized, and each tower section can be equipped with a feed port/temperature measurement port. In order to avoid heat loss during the operation of the tower, modern intelligent instruments are used to set the temperature of the tower to provide heat compensation, so that the experimental process can be closer to the ideal state to a greater extent and achieve better experimental results.

Features

● High separation efficiency and wide application range

● The structure of the tower is simplified, which is suitable for the separation of small and valuable materials

● Accurate control of reflux ratio, which is conducive to the exploration of experimental adjustment

● Precise temperature control, more conducive to the adjustment of experimental conditions

● Batch or continuous distillation

● During the development of the device, computer simulation was introduced to make the operation of the distillation experiment more intelligent

● The structure of the tower is simplified, which is suitable for the separation of small and valuable materials

● Accurate control of reflux ratio, which is conducive to the exploration of experimental adjustment

● Precise temperature control, more conducive to the adjustment of experimental conditions

● Batch or continuous distillation

● During the development of the device, computer simulation was introduced to make the operation of the distillation experiment more intelligent

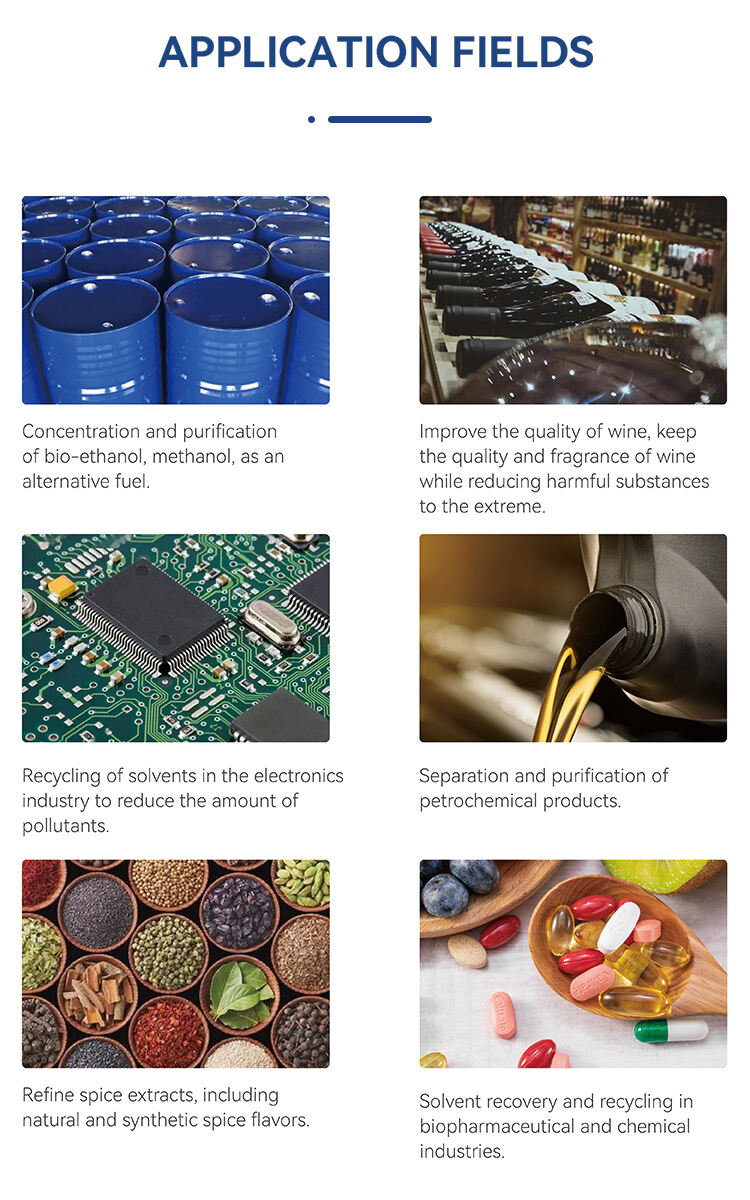

Typical Applications

Fine chemicals, biopharmaceuticals, food and agriculture, new materials, petrochemicals, fragrances and flavors, etc.

Product Parameter

| Model | YFT-5S | YFT-10S | YFT-20S | YFT-50S | YFT-100S |

| Tank volume (L) | 5 | 10 | 20 | 50 | 100 |

| Tower height (m) | 2 | 2 | 2 | 2 | 2 |

| Condensing area (m²) | 0.25 | 0.4 | 0.65 | 1.15 | 1.75 |

| Reflux ratio control | Yes | ||||

| Temp pressure display | Yes | ||||

| Continuous sampling | Yes | ||||

| Working temperature range (℃) | -20-200 ℃ | ||||

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

UK

UK

HU

HU

TH

TH

TR

TR

GA

GA

BE

BE

BN

BN