YFT-5 Galss Rectifying Column Condensing area:0.2 ㎡

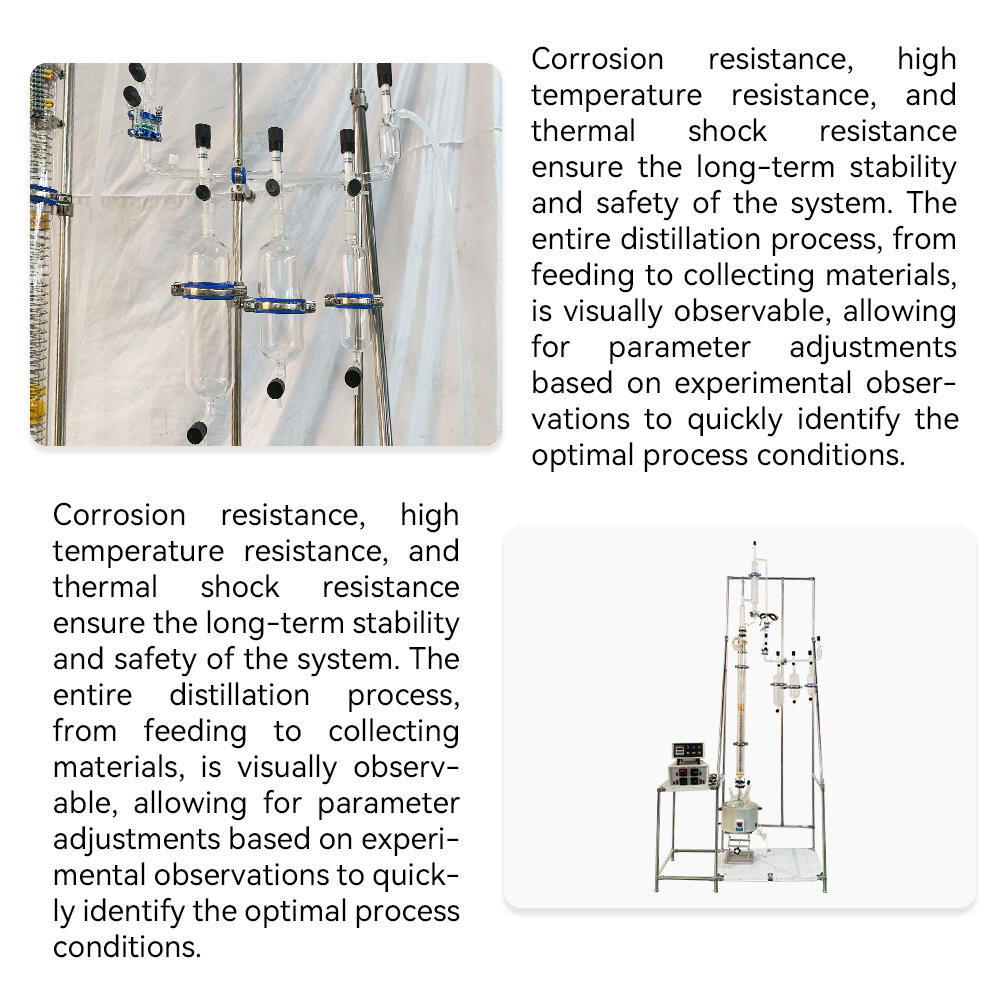

It is made of high borosilicate 3.3 glass corrosion-resistant material or 316L stainless steel material. The volume and tower height can be flexibly customized. It can withstand a maximum temperature of 300°C and an ultimate vacuum of ≤0.098Pa. It is widely used in laboratories and chemical production for efficient gas-liquid mass transfer separation. The equipment can be modularized and combined to meet the needs of multiple scenarios such as fine chemicals and pharmaceuticals.

- PRODUCT DETAILS

- RELATED PRODUCTS

PRODUCT DETAILS

Overview

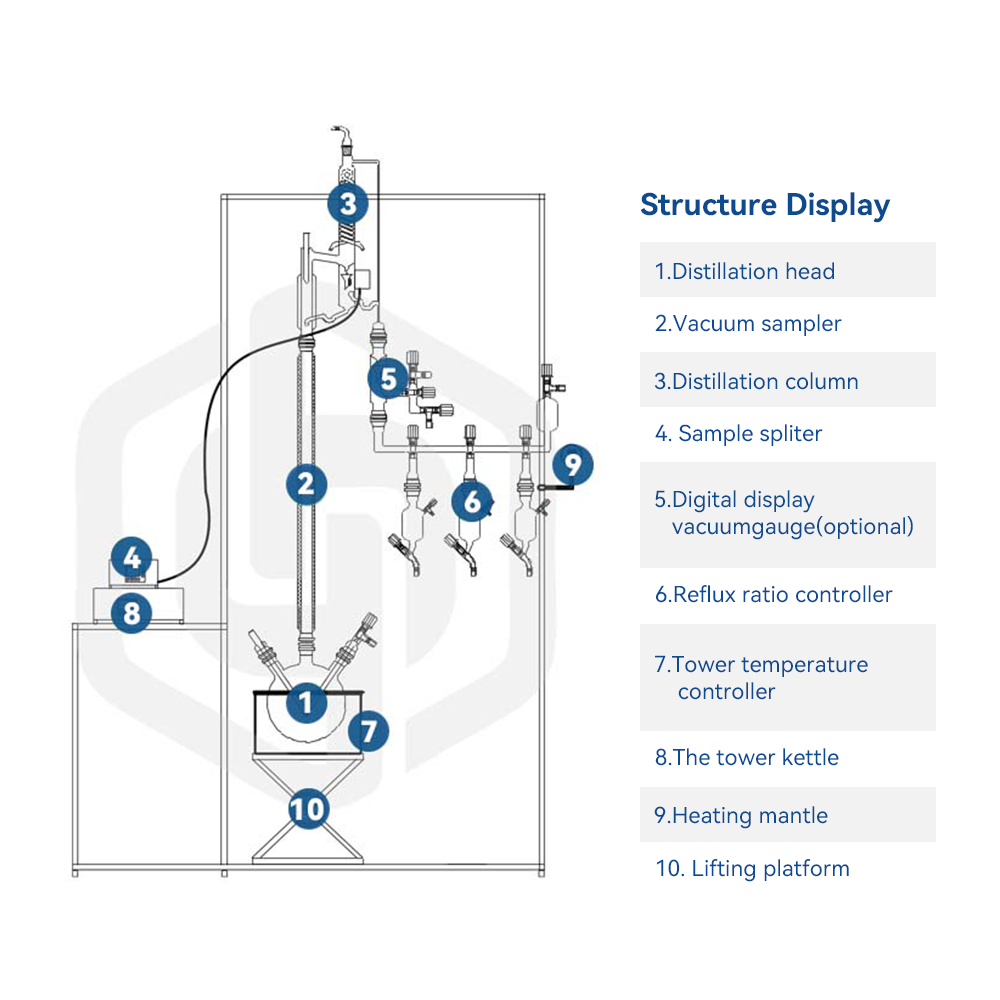

The glass rectifying column is a laboratory or small-scale production distillation equipment made of high-temperature-resistant glass material. It utilizes the

differences in the volatility of various components in a mixed liquid for separation and purification. Its transparent nature facilitates the observation of internal liquid and vapor flow conditions, suitable for research, teaching, and small-scale purification of fine chemicals. By precisely controlling the temperature and reflux ratio, it achieves efficient fractional distillation, especially suitable for materials sensitive to metal ions or requiring contamination avoidance.

differences in the volatility of various components in a mixed liquid for separation and purification. Its transparent nature facilitates the observation of internal liquid and vapor flow conditions, suitable for research, teaching, and small-scale purification of fine chemicals. By precisely controlling the temperature and reflux ratio, it achieves efficient fractional distillation, especially suitable for materials sensitive to metal ions or requiring contamination avoidance.

Features

● Material in contact with the substance: High borosilicate 3.3 glass

● Reboiler volume: 1-200L, customizable for other volumes

● Column height: 0.5-2m, customizable for other heights

● Maximum heating temperature: 300℃

● Minimum operating vacuum: ≤0.1 mbar

● Modular design, flexible replacement of configuration parts or upgrades

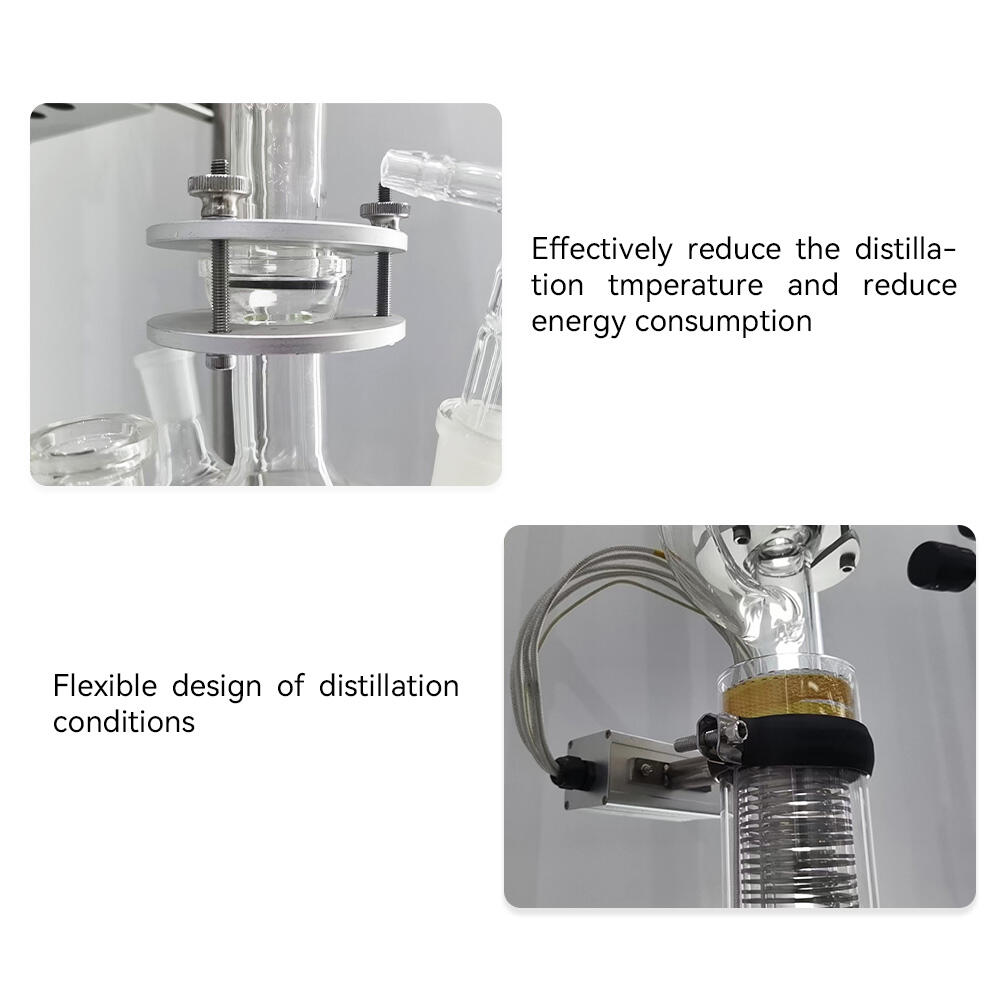

● The high vacuum sealing method can effectively reduce the distillation temperature and reduce energy consumption

● Compact structure and easy disassembly

● Multi-stage temperature control, flexible design of distillation conditions

● Reboiler volume: 1-200L, customizable for other volumes

● Column height: 0.5-2m, customizable for other heights

● Maximum heating temperature: 300℃

● Minimum operating vacuum: ≤0.1 mbar

● Modular design, flexible replacement of configuration parts or upgrades

● The high vacuum sealing method can effectively reduce the distillation temperature and reduce energy consumption

● Compact structure and easy disassembly

● Multi-stage temperature control, flexible design of distillation conditions

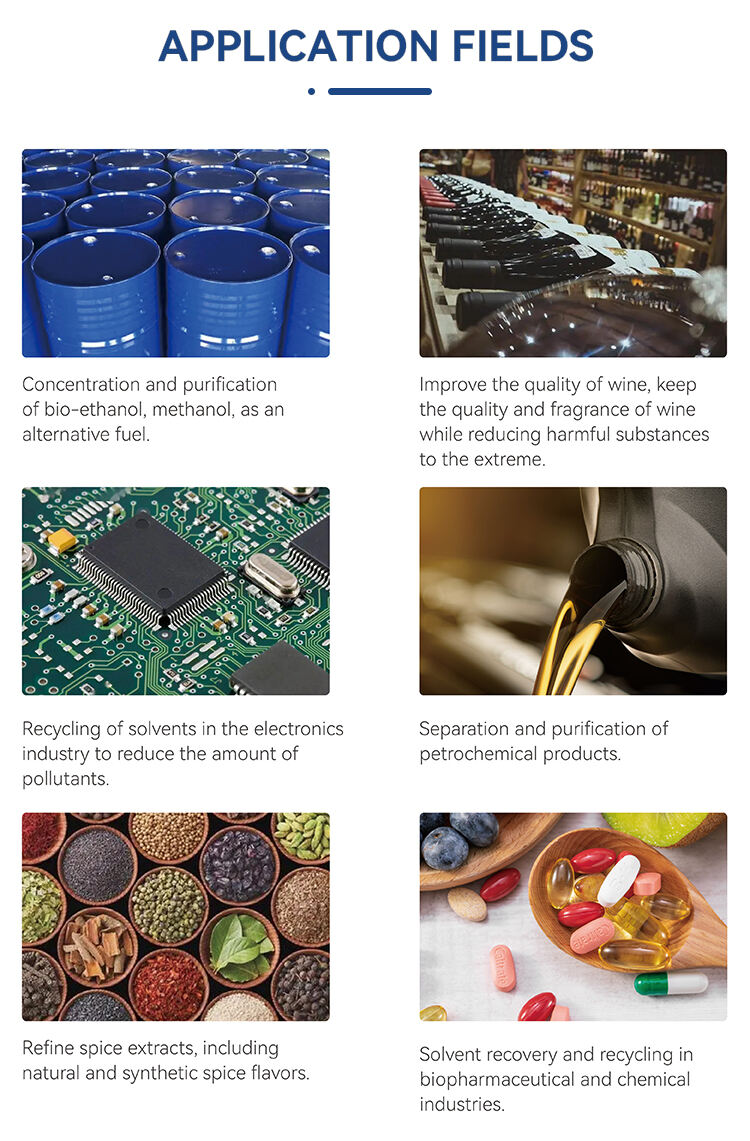

Typical Applications

Product Parameter

| Model | YFT-2 | YFT-5 | YFT-10 | YFT-20 | YFT-50 | YFT-100 |

| Tower kettle volume (L) | 2 | 5 | 10 | 20 | 50 | 100 |

| Tower height (m) | 1 | 1 | 2 | 2 | 2 | 2 |

| Condensing area (m²) | 0.2 | 0.2 | 0.5 | 0.5 | 0.8 | 0.8 |

| Empty vacuum degree(mbar) | ≤1 | |||||

| Working temperature range (℃) | -20-200℃ | |||||

| Reflux ratio control | YES | |||||

| Temp pressure display | YES | |||||

| Continuous sampling | YES | |||||

| Power supply | 220V/50Hz,1P | |||||

SUPPORTING EQUIPMENT

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

UK

UK

HU

HU

TH

TH

TR

TR

GA

GA

BE

BE

BN

BN