YHCHEM High-Purity Fish Oil Refining Solutions: Comprehensive Analysis of Processes, Case Studies, and Core Equipment

Deep-sea fish oil is a natural nutraceutical with exceptionally high nutritional value. It is rich in highly unsaturated fatty acids, most notably the omega-3 polyunsaturated fatty acids eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA). Modern medical research has confirmed that EPA and DHA provide a wide range of important physiological benefits, including lowering blood lipids and cholesterol, promoting the development of the brain and retina, exerting anti-epileptic and anti-arrhythmic effects, and preventing vascular fibrosis. As a result, they play an effective role in the prevention and management of diseases such as hypertension, cardiovascular disease, cancer, and diabetes.

At present, the most commonly used industrial fish oil extraction and purification methods are low-temperature crystallization and urea complexation. Although these techniques are mature and widely applied, they suffer from inherent limitations, including relatively low extraction efficiency and the risk of solvent residues. These drawbacks restrict their suitability for high-purity, high-safety fish oil products. In response to these challenges, YHCHEM offers advanced solutions based on distillation and rectification technologies, enabling fish oil purification across different purity levels while meeting stringent food and nutraceutical standards.

Recommended Fish Oil Production Process – Route 1

Crude fish oil is used as the feedstock and introduced into a customized molecular distillation system designed according to feed composition and processing capacity. Through multi-stage molecular distillation, light-phase impurity components are sequentially removed. As the number of molecular distillation stages increases, the EPA concentration in the light phase gradually increases, while DHA becomes enriched in the heavy phase.

Once the target concentration is achieved, the light-phase and heavy-phase products are collected separately. Throughout the production process, gas chromatography (GC) is applied for real-time analysis and monitoring of fish oil composition, ensuring precise process control and consistent product quality.

Recommended Fish Oil Production Process – Route 2

Crude fish oil is used as the feedstock and processed through a customized system based on feed composition and throughput requirements. A thin-film evaporation unit is first employed to remove light impurities with carbon chain lengths below C18. The resulting heavy phase is then fed into a first-stage rectification column, where low-content short-chain components are further separated.

The heavy fraction obtained from the first rectification stage is rich in EPA, DHA, and other unsaturated fatty acids. Its purity is continuously and accurately monitored using gas chromatography. Subsequently, this enriched fraction enters a second rectification column, where EPA and DHA can be selectively separated according to production requirements. GC analysis of both light and heavy outlet streams confirms whether the target purity has been reached, after which final product collection is completed.

Depending on the characteristics of the raw material, additional process routes can be precisely customized to achieve optimal separation efficiency and product performance.

Typical Case Study

In a representative industrial application, crude fish oil is accurately metered through a feed tank and processed using a multi-stage molecular distillation purification system. After multiple distillation steps, a combined DHA + EPA purity exceeding 90% is achieved.

In real-world production, YHCHEM molecular distillation equipment demonstrates excellent flexibility and adaptability to different material characteristics. When higher purity standards are required, a secondary purification process can be initiated based on the real-time condition of the material. Notably, this can be achieved without operating multiple units in parallel. A single system can perform repeated distillation cycles, balancing purification efficiency with process flexibility. This approach provides a highly efficient and adaptable solution for the production of high-purity fish oil.

Recommended Purification Equipment

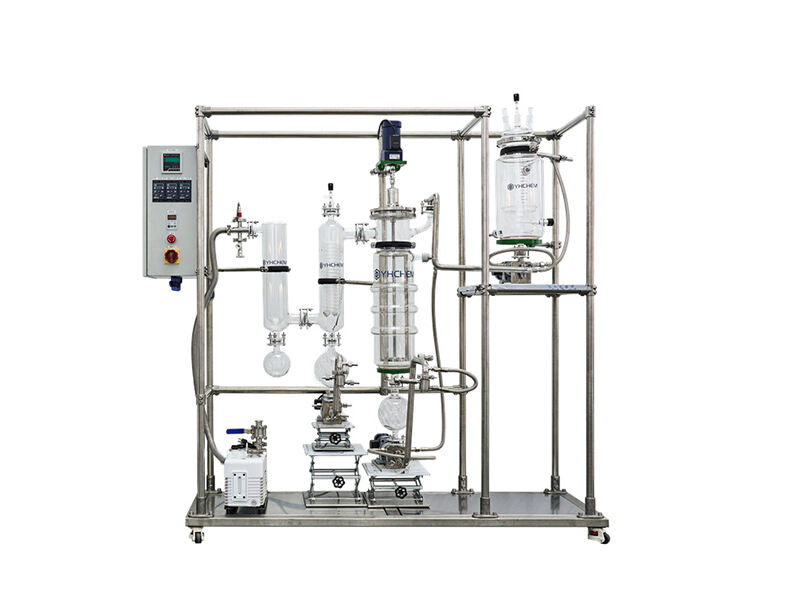

1. Short-Path Molecular Distillation System

Molecular distillation is the core and preferred technology for fish oil purification, as its technical characteristics align perfectly with the properties of fish oil. DHA and EPA are heat-sensitive components, and conventional high-temperature distillation can easily cause oxidation and degradation. Short-path molecular distillation operates under ultra-high vacuum conditions of approximately 10⁻³ Pa, enabling low-temperature separation that bypasses boiling points and effectively preserves bioactive components.

By utilizing differences in molecular mean free paths, the system can precisely retain DHA and EPA while efficiently removing impurities such as heavy metals and free fatty acids. Purity levels above 90% are readily achievable, with support for repeated distillation in a single unit or multi-unit integration to meet ultra-high purity requirements.

The entire process is based on physical separation without the addition of chemical reagents, eliminating the risk of residual contamination and fully complying with food and nutraceutical safety standards. YHCHEM molecular distillation systems feature optimized material flow paths and advanced vacuum control, allowing flexible process customization while balancing efficiency and cost. This makes them the core equipment for producing fish oil with high activity, high purity, and high safety.

2. Thin-Film Distillation System

Thin-film distillation systems use scraper or wiper technology to form a uniform thin film on the inner wall of the main evaporator. This design delivers extremely high heat and mass transfer efficiency, rapid separation, and excellent suitability for continuous industrial production.

The mild operating temperature prevents oxidation and thermal degradation of heat-sensitive components such as DHA and EPA, ensuring maximum retention of biological activity. At the same time, the system efficiently removes free fatty acids, odor-causing substances, and other impurities, significantly improving both purity and overall product quality.

3. Rectification Column System

Rectification column systems operate on the principle of repeated vapor–liquid equilibrium, enabling precise differentiation between DHA, EPA, and difficult-to-remove impurities such as heavy metals and polycyclic aromatic hydrocarbons based on boiling point differences. This allows deep purification and a steady increase in product purity.

These systems support large-scale continuous production with stable throughput, making them well suited for industrial manufacturing. Through vacuum rectification optimization, operating temperatures can be reduced, minimizing oxidation and degradation of heat-sensitive components while maintaining high separation efficiency.

Rectification columns can be used either as a pretreatment step before molecular distillation or as standalone units for preliminary concentration, solvent removal, or medium- to low-vacuum fractionation. Combined with short-path molecular distillation systems, they form a flexible and comprehensive process solution for high-quality fish oil purification.

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

UK

UK

HU

HU

TH

TH

TR

TR

GA

GA

BE

BE

BN

BN