- PRODUCT DETAILS

- RELATED PRODUCTS

PRODUCT DETAILS

Overview

The YUC High Temperature Circulator is a type of closed high-temperature circulator, which adopts electric heating method and outputs heat transfer fluid to heat the materials in the matching reaction vessel through the circulating pump. It is widely used in pharmaceutical and chemical industries and reactor assembly units requiring high-temperature conditions.

Features

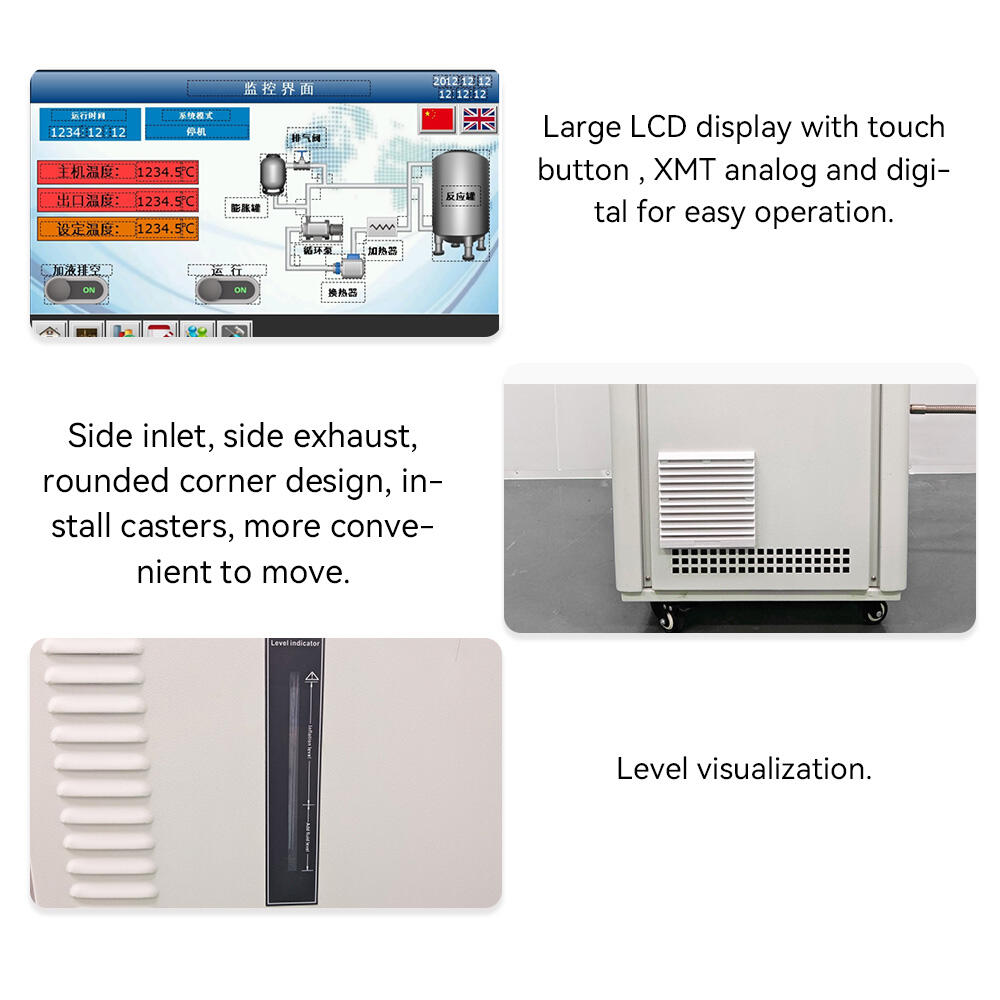

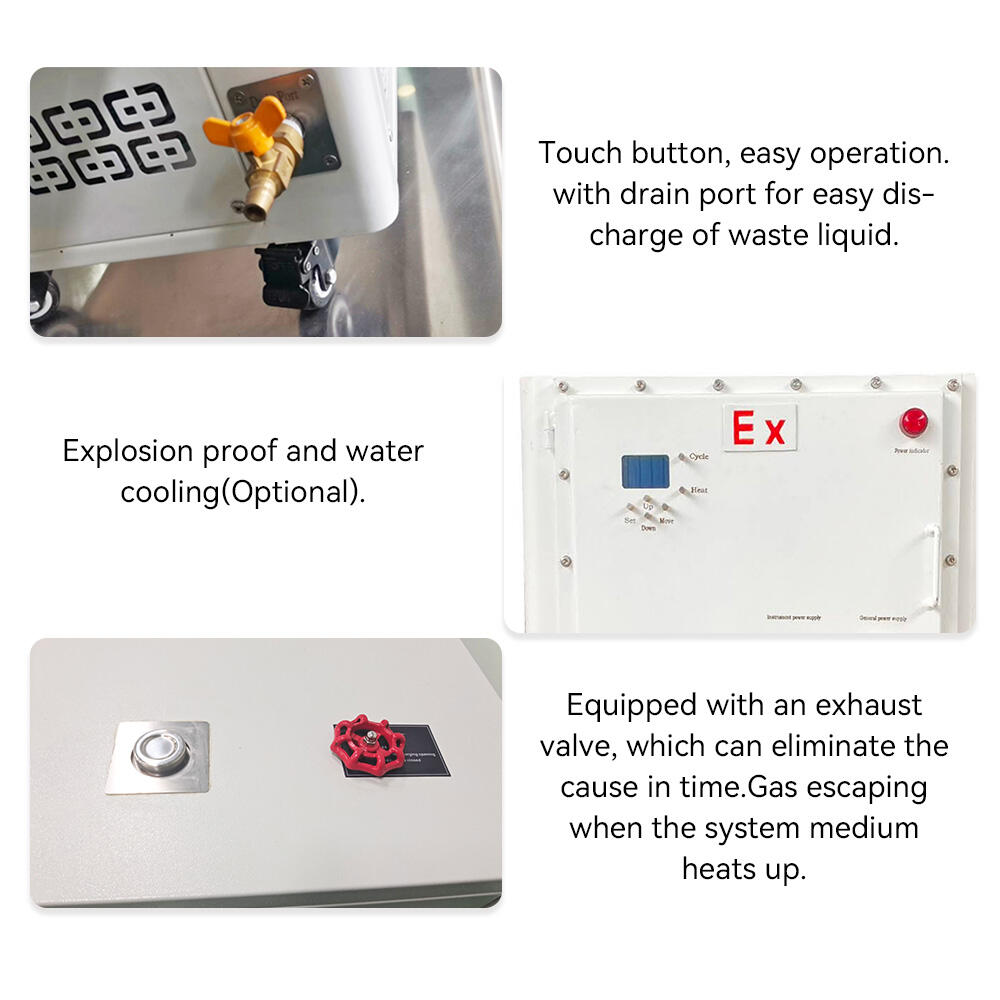

● Equipped with exhaust valve, which can immediately discharge the gas overflowed due to the rise in system medium temperature;

● Equipped with over-temperature alarm function, overload protection, and over-current protection function;

● Temperature control adopts PID method, with high temperature control accuracy;

● Adopting a fully closed-loop circulation system to extend the service life of the heat transfer fluid;

● For Class IIB explosive environments, the equipment can use explosion-proof products of EXdIIBT4/EXdII CT4 grade.

● Inject cooling water to adjust the temperature of the heat transfer fluid quickly to meet the requirements of the process conditions;

● The circulation system adopts stainless steel material, corrosion-resistant, pollution-resistant, and prolonged operating cycle;

● The system temperature control can be heated from room temperature to 300℃

● Certification: CE

● Equipped with over-temperature alarm function, overload protection, and over-current protection function;

● Temperature control adopts PID method, with high temperature control accuracy;

● Adopting a fully closed-loop circulation system to extend the service life of the heat transfer fluid;

● For Class IIB explosive environments, the equipment can use explosion-proof products of EXdIIBT4/EXdII CT4 grade.

● Inject cooling water to adjust the temperature of the heat transfer fluid quickly to meet the requirements of the process conditions;

● The circulation system adopts stainless steel material, corrosion-resistant, pollution-resistant, and prolonged operating cycle;

● The system temperature control can be heated from room temperature to 300℃

● Certification: CE

Typical Applications

High-temperature circulators are widely used in chemical synthesis, petrochemicals, life sciences, pharmaceutical manufacturing, and energy industries, for drug synthesis, distillation separation, emulsification, drying, constant temperature reaction, solution heating and insulation, and other operations. The high-temperature circulator can control the medium temperature with high precision, reliability, and sensitivity, adjust the heating power, separate and collect products to meet various experimental and production needs.

Product Parameter

| YUC-RT~200°C Series | YUC-3020 | YUC-5020 | YUC-10020 | YUC-15020 | YUC-25020 | YUC-38020 | YUC-60020 | |

| Temperature range (℃) | RT~200;±0.5 | RT~200;±1 | ||||||

| Total power(kW) | 3.2 | 5.2 | 10.4 | 15.4 | 25.5 | 39.5 | 62 | |

| Heating method | Electric heating | |||||||

| Voltage(V) | 220V, 50/60Hz, 1P | 380V, 50/60Hz, 3P (Optional 220V/480V) | ||||||

| Temperature Sensor | PT100 | |||||||

| Cooling method | Water cooling | |||||||

| Safety protection | Self-diagnosis; high pressure switch, overload relay, thermal protection device | |||||||

| Expansion tank volume(L) | 10 | 24 | 42 | 70 | 110 | |||

| Heating power(kW) | 3 | 5 | 10 | 15 | 25 | 38 | 60 | |

| Cooling Capacity(KW) 200°C | 3.5 | 5.5 | 10 | 15 | 25 | 38 | 60 | |

| Cooling Capacity(KW) 100°C | 2 | 4 | 8 | 12 | 20 | 30 | 48 | |

| Cooling Capacity(KW) 65°C | 0.6 | 1.8 | 3.4 | 5 | 8.5 | 12 | 19 | |

| Rated flow rate (L/min) | 20 | 42 | 125 | 200 | 315 | |||

| Weight | 68 | 78 | 88 | 100 | 130 | 170 | 285 | |

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

UK

UK

HU

HU

TH

TH

TR

TR

GA

GA

BE

BE

BN

BN