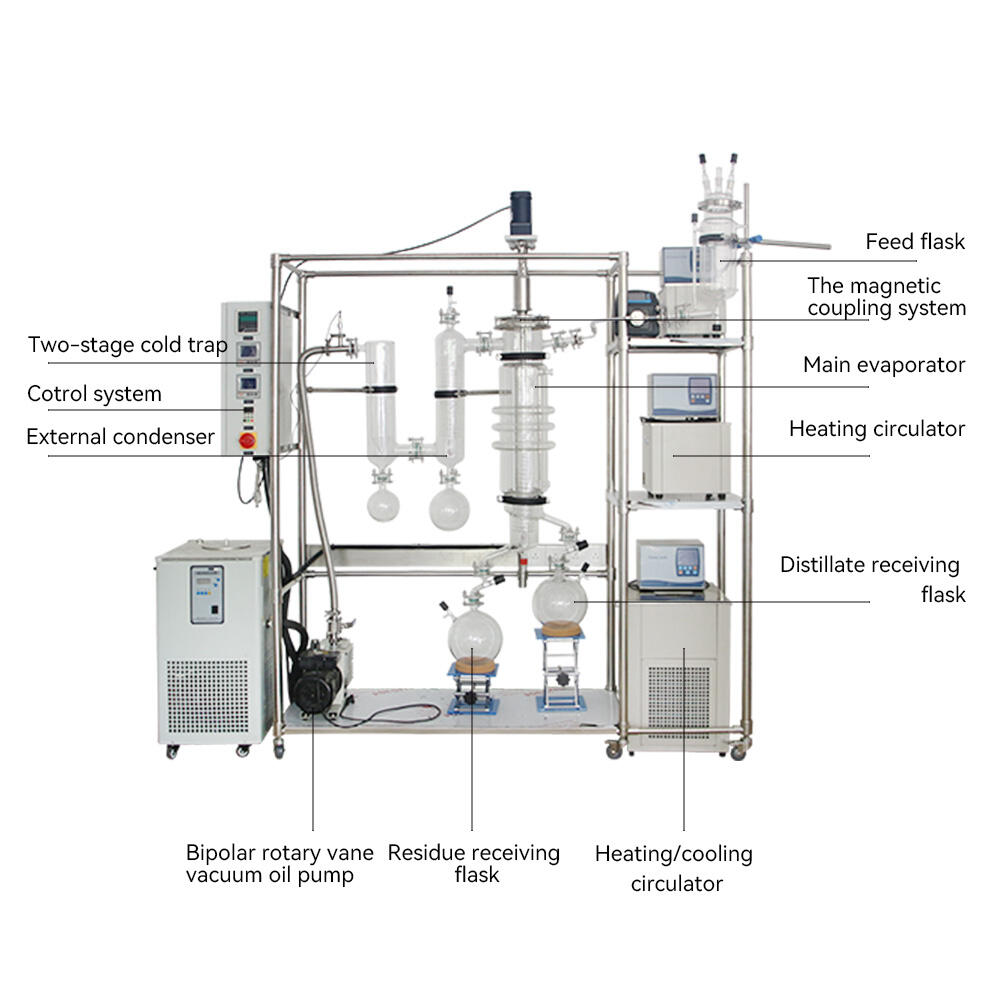

YMD-100 Glass Molecular Distillation Evaporated area: 0.15 ㎡ Treatment capacity: 0.1~5L/h

Low-temperature separation under high vacuum protects heat-sensitive materials, with a purity of up to 99.99%

- PRODUCT DETAILS

- RELATED PRODUCTS

PRODUCT DETAILS

Overview

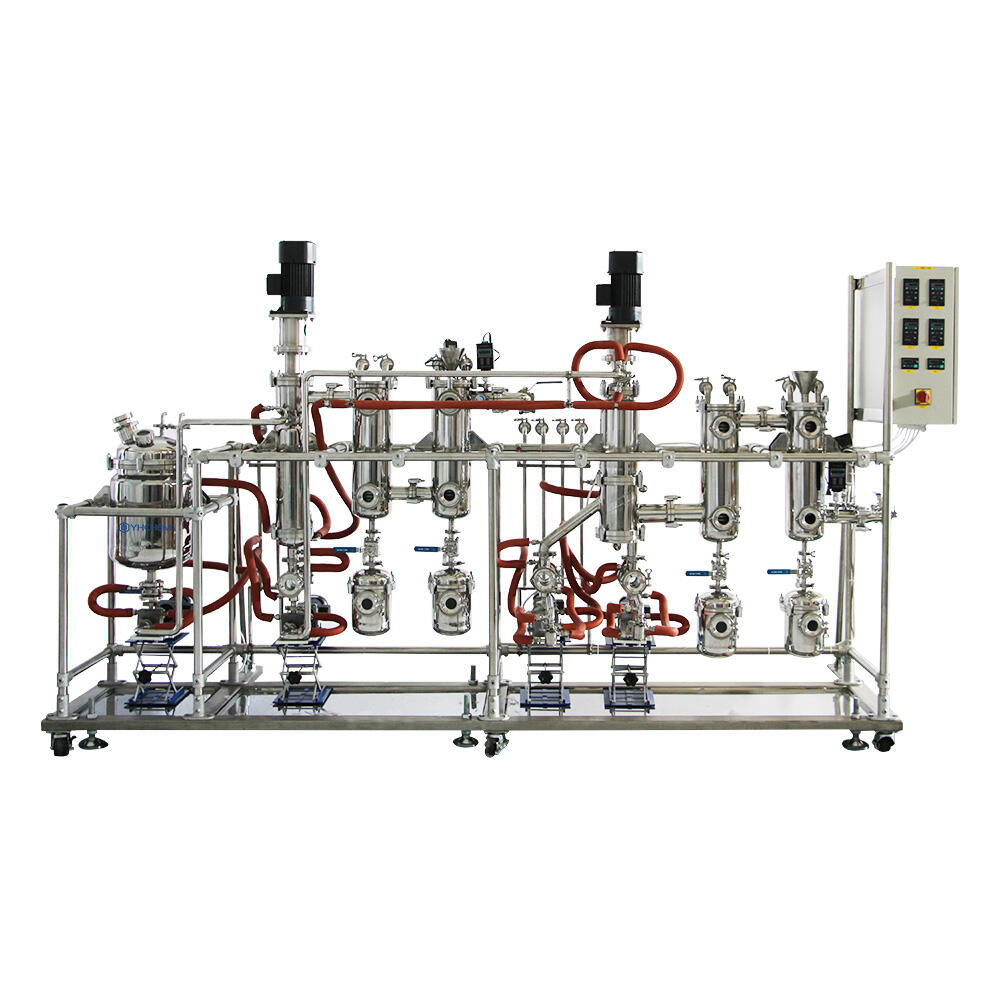

YMD series Wipe Film Molecular Distillation System (Borosilicate Glass) is a type of molecular distillation equipment made of high-boron-silicate 3.3 material. It is mainly used to efficiently and precisely separate and purify components in liquid mixtures. The system uses the short-path molecular distillation principle, where various components in the mixture are evaporated and recondensed at a certain temperature through high-temperature heating, thus achieving the separation and purification of the mixture. Its advantages include easy operation, easy cleaning, wide applicability, efficient purification, high vacuum degree, intuitive visualization of the distillation process, corrosion resistance, etc., making it an ideal choice for experimental research or small-scale production.

Features

● The glass parts are made of high borosilicate 3.3 material, with excellent visibility.

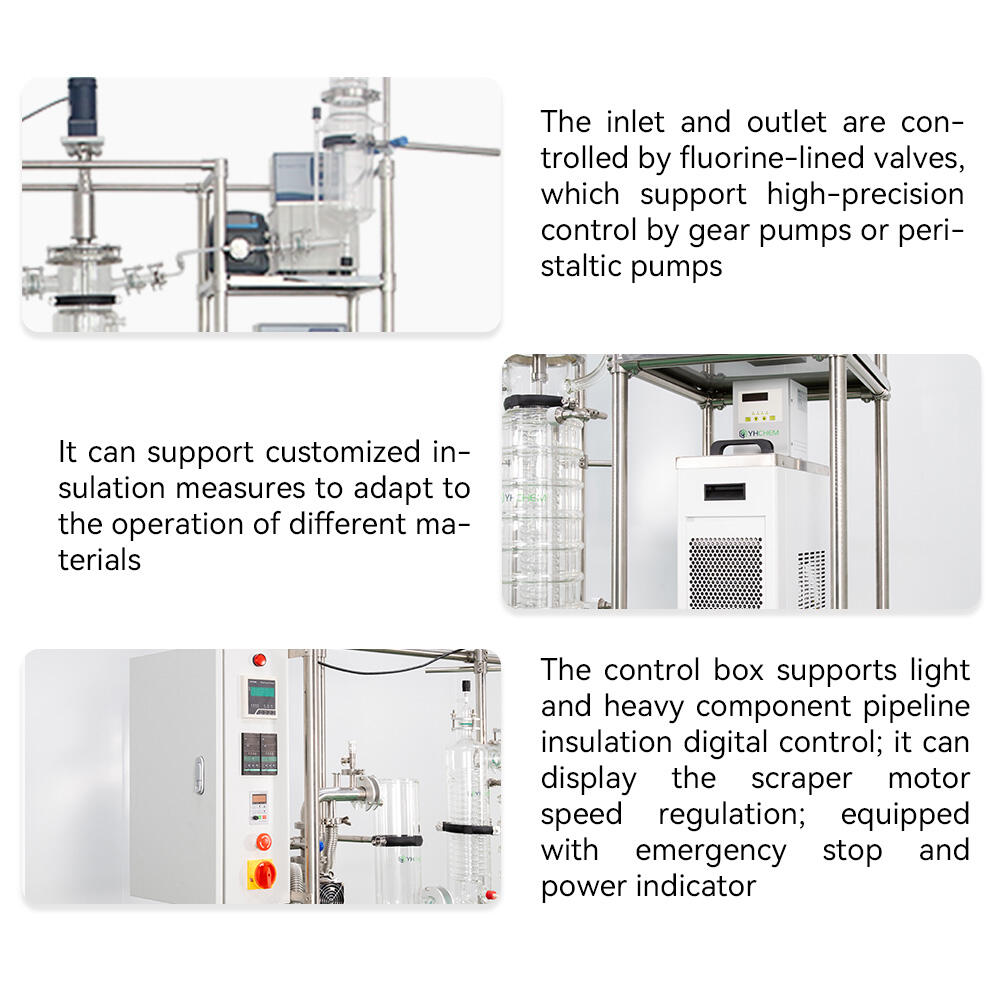

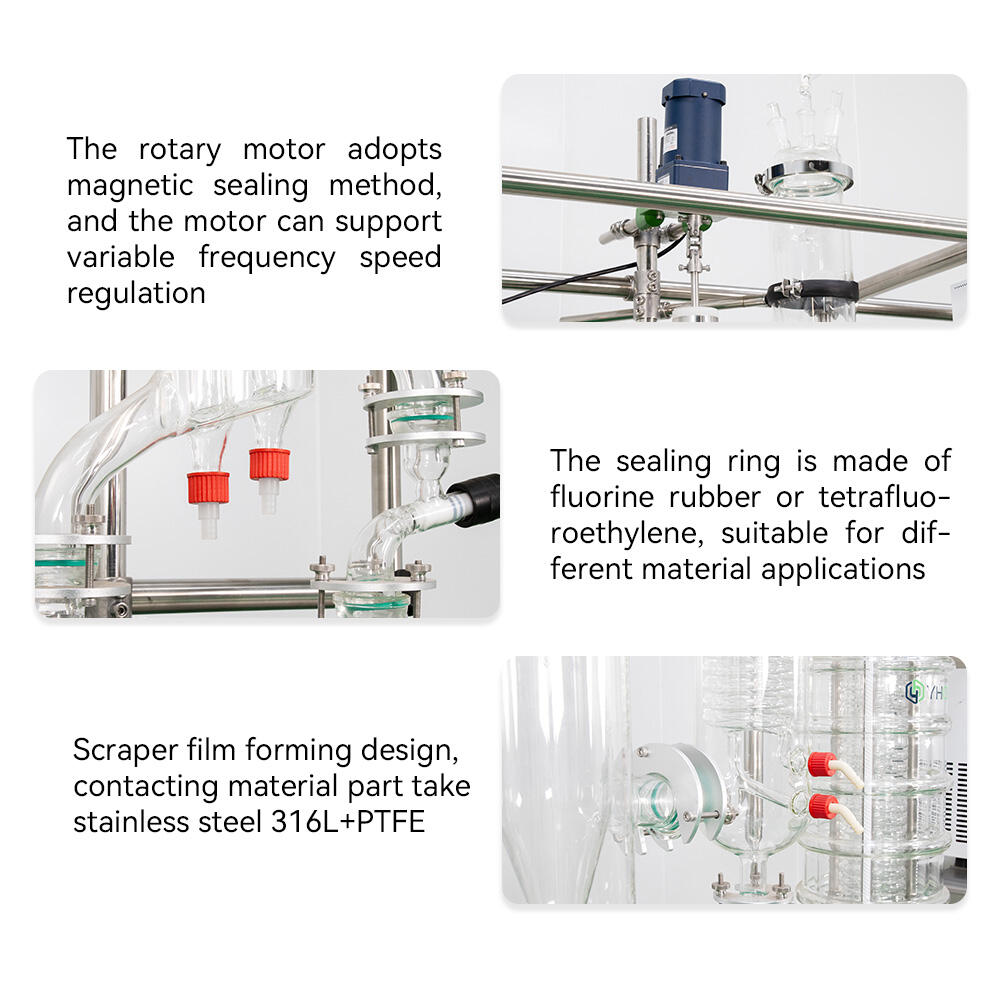

● The magnetic coupling seal can maintain a higher vacuum degree to ensure the evaporation effect.

● Scraper film forming design, contacting material part take stainless steel 316L+PTFE.

● The sealing ring is made of fluorine rubber or tetrafluoroethylene, suitable for different material applications.

● The main evaporator have been designed with full jacket and full insulation to ensure material fluidity.

● Digital display pirani vacuum gauge, display high vacuum number.

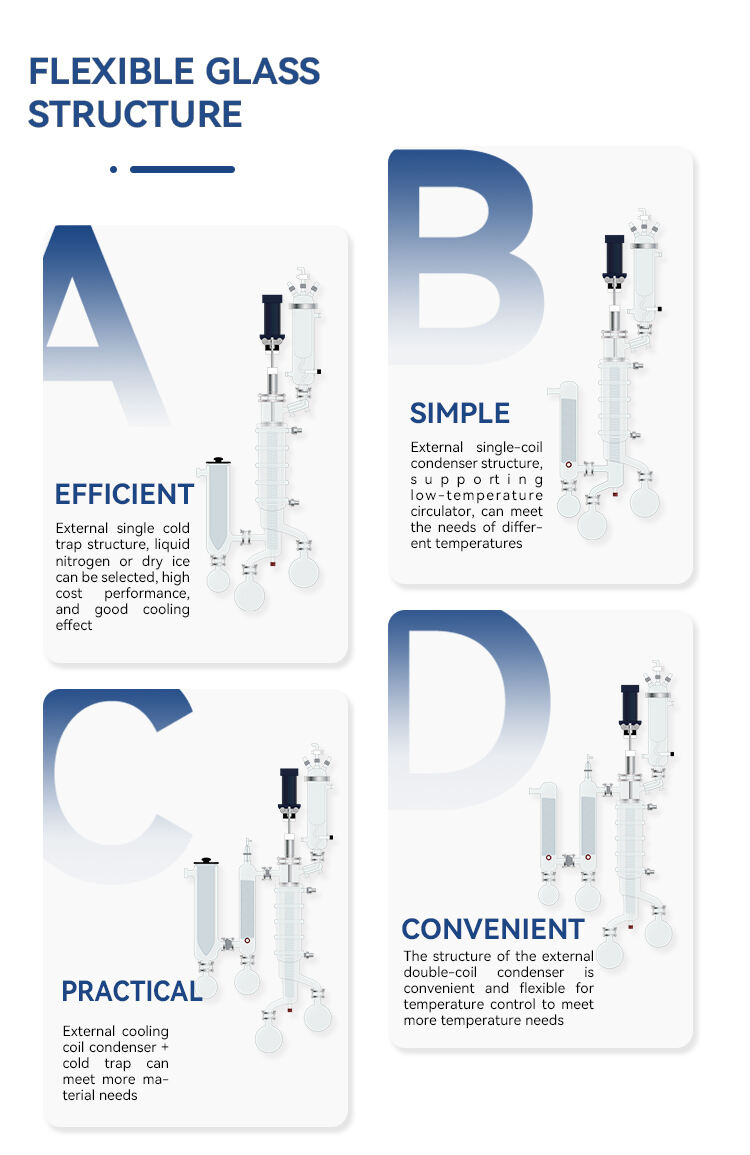

● Multi-plan structure configuration to guarantee different material and different process requirements.

● Certification:UL、CE.

● The magnetic coupling seal can maintain a higher vacuum degree to ensure the evaporation effect.

● Scraper film forming design, contacting material part take stainless steel 316L+PTFE.

● The sealing ring is made of fluorine rubber or tetrafluoroethylene, suitable for different material applications.

● The main evaporator have been designed with full jacket and full insulation to ensure material fluidity.

● Digital display pirani vacuum gauge, display high vacuum number.

● Multi-plan structure configuration to guarantee different material and different process requirements.

● Certification:UL、CE.

Typical Applications

| Biopharmaceuticals | Fine Chemicals | Food and Agriculture | Daily Chemicals | Fragrances and Flavors | Petrochemical Industry |

| (Deep-Sea and Fermented) Fish Oil | (Bisphenol A and F type) Epoxy Resin | Elaeagnus Mollis Oil | Polyethylene Glycol Ester | 3-Methylindole | B12042 |

| Docosahexaenoic Acid (DHA) | Triethylene Glycol | Polyethylene Glycol Ester | L-Lactic Acid | Cedarwood Oil | Waste Oil Regeneration |

| Eicosapentaenoic Acid (EPA) | 3-Hydroxypropionitrile (HPN) | Cholesterol-Removed (Beef Tallow and Lard) | Amino Acid Ester | Methyl Propionate | Glycerol Wastewater Recovery |

| Polyether | Triethylene Glycol | Tocopherol (Natural and Synthetic) | Menthyl Ester | Angelica Extract | Saline Wastewater |

| Methyl Salicylate | Alkylphenol | Sage Antioxidant | Lanolin Alcohol | Patchouli Oil (Patchoulol, Patchoulone) | Sulfonated Kerosene |

| Glycolipid | Microcrystalline Wax | Alkyl Glycoside | Tea Tree Oil | Methyl Heptenone | Polyglycerol Ester |

| Vitamin A | Polyolefin | Nicotine Purification | Lanolin | m-Toluic Acid | Polyether |

| Vitamin E Acetate | Tributyl Phosphate | Glyoxylic Acid | Jasmine Essential Oil | Citral | Polyether Polyol |

| Vitamin K Purification | Triethyl Phosphate | Organosilane Resin | Cane Wax | Cinnamaldehyde (Cinnamon Oil) | Mineral Oil Sludge Dewaxing |

| Laurocapram | Neopentyl Glycol Dicaprylate | Sterol Ester | Litsea Cubeba Oil | Litsea Cubeba Oil | Asphalt Dewaxing |

| Psoralea Corylifolia | Silicone Oil | Phytosterol | Peach Aldehyde | Methyl Salicylate | Coal Tar |

| Ibuprofen Pivalate | Plasticizer | Perilla Seed Oil | Cetyl Alcohol | Sandalwood | Nano Pigment Removal of Toluene |

| Tea Tree Oil | Polyhydric Alcohol | Palm Oil | Polydimethylsiloxane | Peach Aldehyde | Biodiesel (Fatty Acid Methyl Ester or Ethyl Ester) |

| Bupleurum Volatile Oil | Dimer Acid | Monoglyceride (Monostearin, Monolaurin, etc.) | Vetiver Oil | Vetiver Oil | Graphite Acid Dehydration |

| Agarwood | Silicone Oil (Polysiloxane or Polysilicone Ether) | Polysaccharide Ester | Polyglycerol Ester | Geraniol | Petroleum Residual Oil |

| Garlic Oil | Aromatic Isocyanate | Lycopene | Polyether Silicone | Synthetic Jasmine Aldehyde | Hydrocarbon Compound |

| Monoglyceride | Fluorinated Oil (Perfluorocarbon, Fluorochlorocarbon Oil, Perfluoropolyether) | Conjugated Linoleic Acid | Polyolefin | Long-Chain Dicarboxylic Acid (C9-C18) | Glutaraldehyde |

| Polyunsaturated Fatty Acids | Glycerol | Silicone Oil (Dimethylpolysiloxane) | Polyethylene Glycol (Ester) | Ionone | Liquefied Coal |

| Peptide | Curing Agent (Removing TDI, MDI, HDI, etc.) | Walnut Oil | Capsaicin | Vacuum Pump Oil | |

| Entecavir Intermediate 7 | Silane Coupling Agent | Squalene | Rose Oil | Brake Fluid |

Product Parameter

| Model | YMD-60 | YMD-80 | YMD-100 | YMD-150 | YMD-200 |

| Feeding rate (L/h) | 0.05~2 | 0.05~3 | 0.1~5 | 0.2~10 | 0.5~15 |

| Effective evaporation area (m²) | 0.07 | 0.1 | 0.15 | 0.25 | 0.35 |

| Cooling area of internal condenser (m²) | 0.15 | 0.2 | 0.3 | 0.53 | 0.73 |

| Feeding flask volume (L) | 0.5 | 1 | 1 | 2 | 3 |

| Residue receiving flask (L) | 0.5 | 1 | 2 | 5 | |

| Distillate receiving flask (L) | 0.5 | 1 | 2 | 5 | |

| Rotation speed (rpm) | 50~300 | 50~500 | |||

| Vaccum Level (mbar) | ≤0.01 | ||||

| Operation temperature (℃) | ≤300 | ||||

| Power supply | 220V,50/60Hz; 1P | ||||

SUPPORTING EQUIPMENT

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

UK

UK

HU

HU

TH

TH

TR

TR

GA

GA

BE

BE

BN

BN