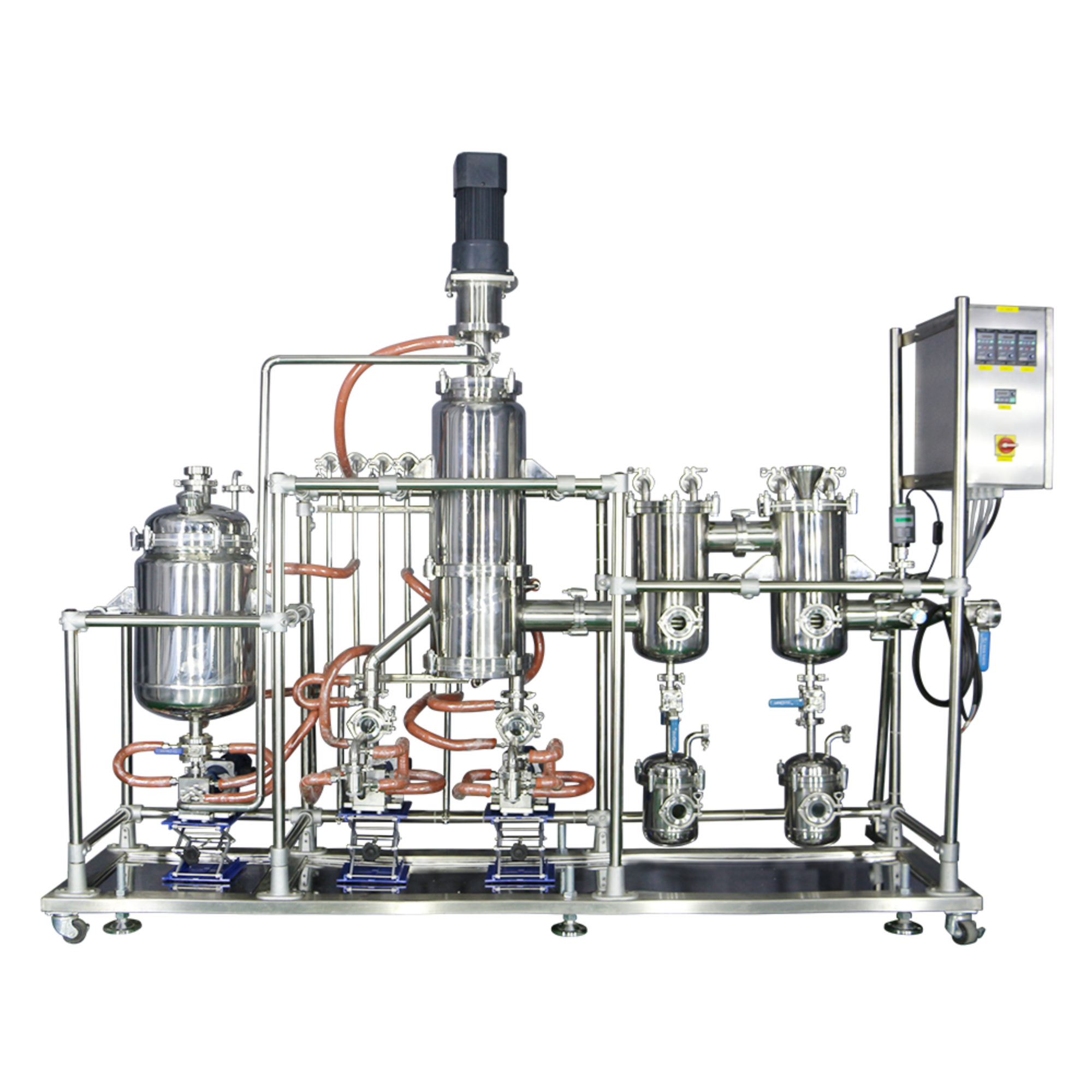

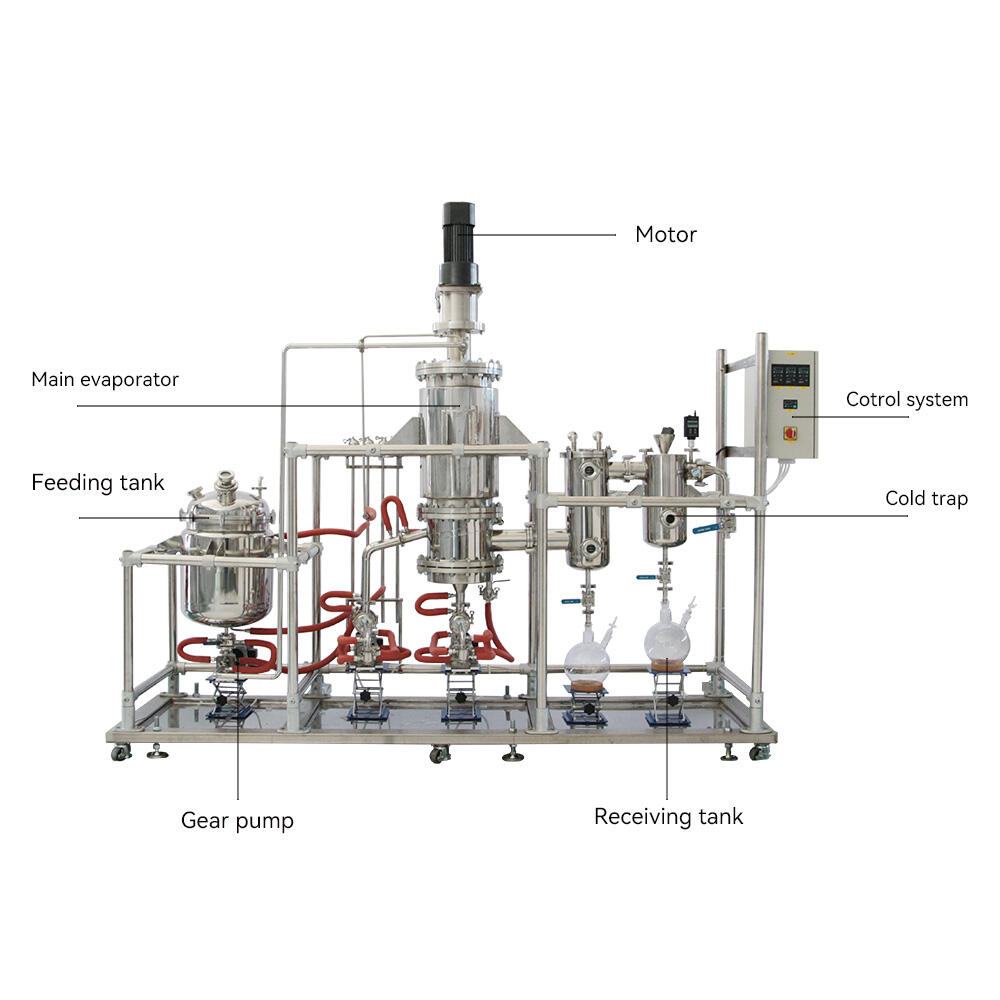

YMD-3S Stainless Steel Molecular Distillation Evaporated area: 0.3㎡ Treatment capacity: 2~30L/h

Low-temperature separation under high vacuum protects heat-sensitive materials, with a purity of up to 99.99%

- PRODUCT DETAILS

- RELATED PRODUCTS

PRODUCT DETAILS

Overview

YMD-S series Wipe Film Molecular Distillation System(Stainless Steel) is a type of molecular distillation equipment made of stainless steel, featuring high corrosion resistance and high temperature resistance. This system adopts the short path molecular distillation principle, heating the mixture to a high temperature to make each component evaporate separately and then re-condense at a certain temperature, thus achieving the separation and purification of the mixture. The stainless steel short path molecular distillation system has higher integration and better heat transfer efficiency, and can greatly increase productivity through the high-precision automatic feeding and discharge pump. It is an ideal choice for pilot and industrial production equipment.

Features

● Unique full jacket and full insulation design

1. Jacket design of feed tank, transfer heating oil preheating and heating preservation function.

2. The outlet jacket design for light and heavy components makes the material flow smoothly.

3. Jacket design of automatic feeding and discharging pump head to prevent material blocking from happening.

4. The thermal insulation design of the full jacket pipe reach the using area of different materials and accelerates the material processing rate.

● Modular design, flexible selection

1.High-precision automatic feeding and discharging pump, with high degree of automation, to save labor manpower and working time.

2.The independent magnetic coupling sealing structure does not affect the vacuum system of the module, ensuring an excellent vacuum effect.

3.Standard interface connection can be matched with different external condenser requirements according to process requirements.

4.Standard port connection for supporting heating and refrigeration equipment, easy to match.

5. According to the requirements of vacuum degree, it can be matched with different vacuum units to realize two-stage or multi-stage pump connection.

● Strict processing and process design to meet the use of different fields

1 . High-precision polishing treatment of the inner wall of the barrel, smooth and clean, not easy to stick and scale.

2. The material in contact with the material is made of stainless steel 316L+PTFE, with high heat transfer efficiency and excellent corrosion resistance.

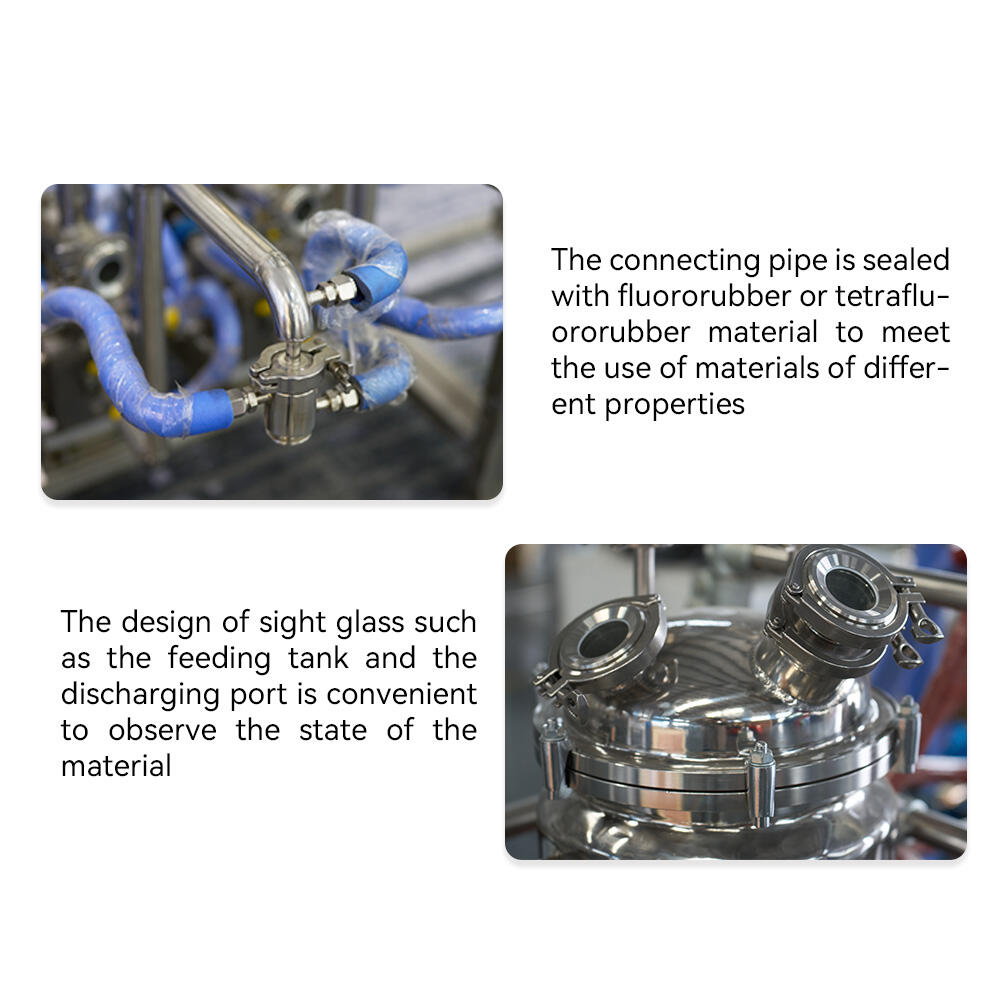

3. The connecting pipe is sealed with fluororubber or tetrafluororubber material to meet the use of materials of different properties.

4. The design of sight glass such as the feeding tank and the discharging port is convenient to observe the state of the material.

5. Brand gear motor with frequency conversion, safe and reliable operation, can work continuously for a long time.

6.The explosion-proof configuration of the whole system for optional.

● Authoritative release of equipment, the whole system meets UL/CE certification.

1. Jacket design of feed tank, transfer heating oil preheating and heating preservation function.

2. The outlet jacket design for light and heavy components makes the material flow smoothly.

3. Jacket design of automatic feeding and discharging pump head to prevent material blocking from happening.

4. The thermal insulation design of the full jacket pipe reach the using area of different materials and accelerates the material processing rate.

● Modular design, flexible selection

1.High-precision automatic feeding and discharging pump, with high degree of automation, to save labor manpower and working time.

2.The independent magnetic coupling sealing structure does not affect the vacuum system of the module, ensuring an excellent vacuum effect.

3.Standard interface connection can be matched with different external condenser requirements according to process requirements.

4.Standard port connection for supporting heating and refrigeration equipment, easy to match.

5. According to the requirements of vacuum degree, it can be matched with different vacuum units to realize two-stage or multi-stage pump connection.

● Strict processing and process design to meet the use of different fields

1 . High-precision polishing treatment of the inner wall of the barrel, smooth and clean, not easy to stick and scale.

2. The material in contact with the material is made of stainless steel 316L+PTFE, with high heat transfer efficiency and excellent corrosion resistance.

3. The connecting pipe is sealed with fluororubber or tetrafluororubber material to meet the use of materials of different properties.

4. The design of sight glass such as the feeding tank and the discharging port is convenient to observe the state of the material.

5. Brand gear motor with frequency conversion, safe and reliable operation, can work continuously for a long time.

6.The explosion-proof configuration of the whole system for optional.

● Authoritative release of equipment, the whole system meets UL/CE certification.

Typical Applications

| Biopharmaceuticals | Fine Chemicals | Food and Agriculture | Daily Chemicals | Fragrances and Flavors | Petrochemical Industry |

| (Deep-Sea and Fermented) Fish Oil | (Bisphenol A and F type) Epoxy Resin | Elaeagnus Mollis Oil | Polyethylene Glycol Ester | 3-Methylindole | B12042 |

| Docosahexaenoic Acid (DHA) | Triethylene Glycol | Polyethylene Glycol Ester | L-Lactic Acid | Cedarwood Oil | Waste Oil Regeneration |

| Eicosapentaenoic Acid (EPA) | 3-Hydroxypropionitrile (HPN) | Cholesterol-Removed (Beef Tallow and Lard) | Amino Acid Ester | Methyl Propionate | Glycerol Wastewater Recovery |

| Polyether | Triethylene Glycol | Tocopherol (Natural and Synthetic) | Menthyl Ester | Angelica Extract | Saline Wastewater |

| Methyl Salicylate | Alkylphenol | Sage Antioxidant | Lanolin Alcohol | Patchouli Oil (Patchoulol, Patchoulone) | Sulfonated Kerosene |

| Glycolipid | Microcrystalline Wax | Alkyl Glycoside | Tea Tree Oil | Methyl Heptenone | Polyglycerol Ester |

| Vitamin A | Polyolefin | Nicotine Purification | Lanolin | m-Toluic Acid | Polyether |

| Vitamin E Acetate | Tributyl Phosphate | Glyoxylic Acid | Jasmine Essential Oil | Citral | Polyether Polyol |

| Vitamin K Purification | Triethyl Phosphate | Organosilane Resin | Cane Wax | Cinnamaldehyde (Cinnamon Oil) | Mineral Oil Sludge Dewaxing |

| Laurocapram | Neopentyl Glycol Dicaprylate | Sterol Ester | Litsea Cubeba Oil | Litsea Cubeba Oil | Asphalt Dewaxing |

| Psoralea Corylifolia | Silicone Oil | Phytosterol | Peach Aldehyde | Methyl Salicylate | Coal Tar |

| Ibuprofen Pivalate | Plasticizer | Perilla Seed Oil | Cetyl Alcohol | Sandalwood | Nano Pigment Removal of Toluene |

| Tea Tree Oil | Polyhydric Alcohol | Palm Oil | Polydimethylsiloxane | Peach Aldehyde | Biodiesel (Fatty Acid Methyl Ester or Ethyl Ester) |

| Bupleurum Volatile Oil | Dimer Acid | Monoglyceride (Monostearin, Monolaurin, etc.) | Vetiver Oil | Vetiver Oil | Graphite Acid Dehydration |

| Agarwood | Silicone Oil (Polysiloxane or Polysilicone Ether) | Polysaccharide Ester | Polyglycerol Ester | Geraniol | Petroleum Residual Oil |

| Garlic Oil | Aromatic Isocyanate | Lycopene | Polyether Silicone | Synthetic Jasmine Aldehyde | Hydrocarbon Compound |

| Monoglyceride | Fluorinated Oil (Perfluorocarbon, Fluorochlorocarbon Oil, Perfluoropolyether) | Conjugated Linoleic Acid | Polyolefin | Long-Chain Dicarboxylic Acid (C9-C18) | Glutaraldehyde |

| Polyunsaturated Fatty Acids | Glycerol | Silicone Oil (Dimethylpolysiloxane) | Polyethylene Glycol (Ester) | Ionone | Liquefied Coal |

| Peptide | Curing Agent (Removing TDI, MDI, HDI, etc.) | Walnut Oil | Capsaicin | Vacuum Pump Oil | |

| Entecavir Intermediate 7 | Silane Coupling Agent | Squalene | Rose Oil | Brake Fluid |

Product Parameter

| Model | YMD-06S | YMD-1S | YMD-2S | YMD-3S | YMD-5S | YMD-10S | YMD-20S | YMD-50S |

| Feeding rate (L/h) | 1~5 | 1.5~6 | 5~20 | 5~25 | 5~25 | 20~100 | 20~100 | 100~300 |

| Effective evaporation area(m²) | 0.06 | 0.1 | 0.2 | 0.3 | 0.5 | 1 | 2 | 5 |

| Feeding flask volume(L) | 10 | 15 | 30 | 50 | 100 | 100 | 200 | |

| Vaccum Level (mbar) | ≤0.01 mbar | |||||||

| Operation temperature (℃) | ≤350 °C | |||||||

| Power supply | 220V,50/60Hz; 1P | |||||||

| Equipment height(cm) | 180 | 200 | 235 | 265 | 330 | 445 | 500 | 750 |

SUPPORTING EQUIPMENT

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

UK

UK

HU

HU

TH

TH

TR

TR

GA

GA

BE

BE

BN

BN