YWT-S Series Stainless Steel Thin Film Rectifying Column

The unique thin-film evaporator + distillation column coupling technology has completely solved the problem of high-temperature decomposition of heat-sensitive materials. Vacuum degree ≤0.1mbar, short residence time, one-step purification replacing multiple processes, high borosilicate glass/stainless steel dual material options, flexible customization from 1 to 200L, preferred equipment for biopharmaceuticals, food extraction, and fine chemicals

- PRODUCT DETAILS

- RELATED PRODUCTS

PRODUCT DETAILS

Overview

Thin film rectifying columnn is a device that couples a thin film evaporator with a rectifying column. During the distillation process, the thin film rectifying columnn can address the issue of thermal decomposition of heat-sensitive materials caused by excessive bottom temperatures and prolonged residence time in the reboiler. The excellent features of the thin film rectifying columnn, such as vacuum, film scraping, and distillation, can be widely applied in industries such as biopharmaceuticals, food, plant extraction, and chemicals.

The thin film rectifying columnn effectively prevents materials from undergoing degradation reactions such as decomposition, polymerization, and oxidation due to heat, thus protecting the properties of the product materials. Compared to traditional thin film evaporators, the film distillation column adds the function of distillation, which enhances the product's purity and reduces the number of purification steps required.

The thin film rectifying columnn effectively prevents materials from undergoing degradation reactions such as decomposition, polymerization, and oxidation due to heat, thus protecting the properties of the product materials. Compared to traditional thin film evaporators, the film distillation column adds the function of distillation, which enhances the product's purity and reduces the number of purification steps required.

Features

● Continuous and stable feeding method, compact equipment with a small footprint.

● High-boiling materials can achieve low-temperature evaporation under high vacuum.

● High evaporation efficiency and good separation performance.

● Prevents materials from undergoing decomposition, polymerization, oxidation, or other degradation reactions due to heat, effectively protecting the properties of the product.

● Added distillation function, which enhances product purity and reduces purification process steps.

● High-boiling materials can achieve low-temperature evaporation under high vacuum.

● High evaporation efficiency and good separation performance.

● Prevents materials from undergoing decomposition, polymerization, oxidation, or other degradation reactions due to heat, effectively protecting the properties of the product.

● Added distillation function, which enhances product purity and reduces purification process steps.

Typical Applications

Fine Chemicals, Biopharmaceuticals, Food and Agriculture, New Materials, Petrochemicals, Fragrances and Flavors.

Product Parameter

| Model | YWT-1S | YWT-2S | YWT-3S | YWT-5S | YWT-10S | YWT-20S |

| Raw material tank volume(L) | 15 | 15 | 15 | 30 | 100 | 100 |

| Evaporation area(m²) | 0.1 | 0.2 | 0.3 | 0.5 | 1 | 2 |

| Cold trap(㎡) | 0.4 | 0.4 | 0.5 | 1.3 | 1.3 | 1.3 |

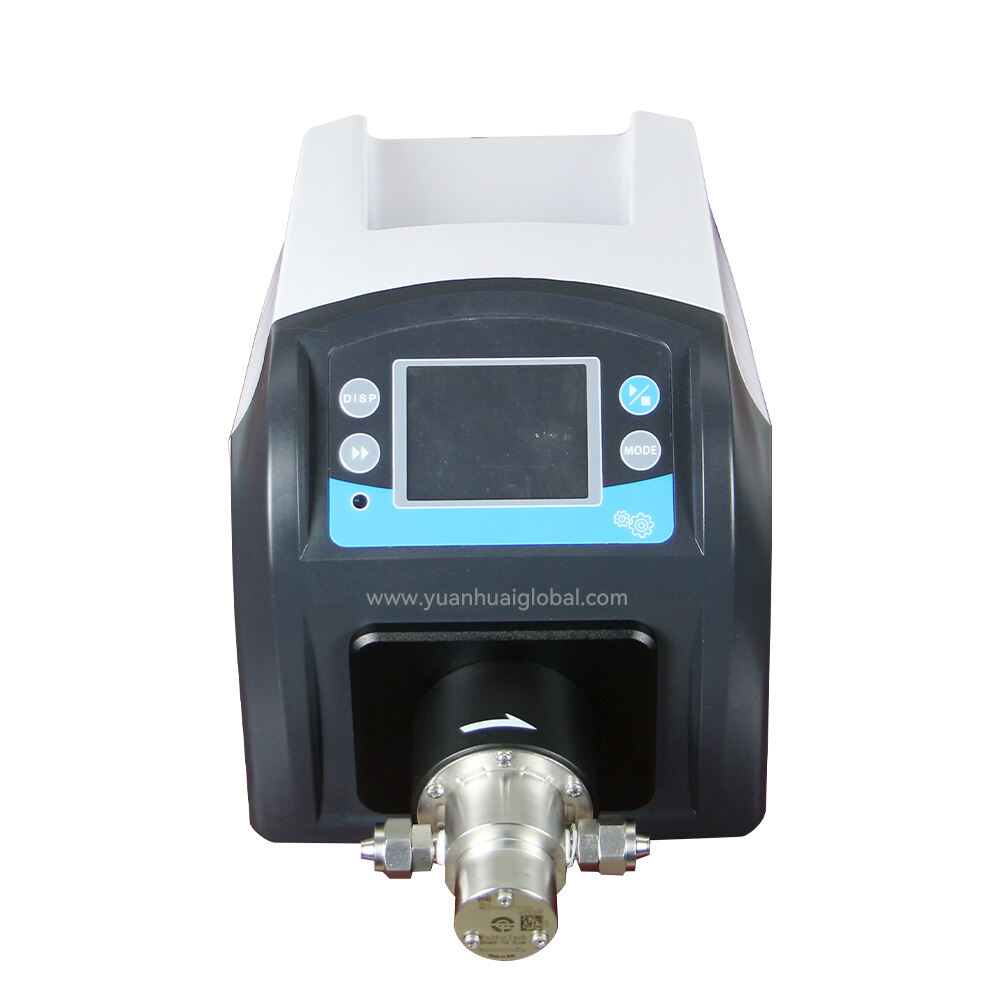

| Feed gear pump flow rate(L/h) | 1.5~6 | 1.5~6 | 1.5~6 | 3~15 | 10~50 | 20~100 |

| Heavy discharge gear pump flow rate(L/h) | 1.5~6 | 1.5~6 | 1.5~6 | 3~15 | 10~50 | 20~100 |

| Light discharge gear pump flow rate(L/h) | 1.5~6 | 1.5~6 | 1.5~6 | 3~15 | 10~50 | 20~100 |

| Light discharge gear pump motor power(W) | 200W,Frequency converter | 550W,Frequency converter | ||||

| Heavy discharge gear pump motor power(W) | 200W,Frequency converter | 550W,Frequency converter | ||||

| Material pipeline | Jacket insulation, inner layer 316L, jacket 304 | |||||

| Film formation method | Scraper | |||||

| Material | 316L | |||||

| Sealing method | Machinery seal | |||||

| Bracket and assembly | 304 stainless steel pipe | |||||

| Distillation column | L1=600,L2=400; | L1=800,L2=400; | L1=1000,L2=500; | |||

| Reflow ratio controller | Magnetic reflux ratio controller | |||||

| Gear pump motor power(W) | 120 motor,Electronic speed regulation | 200 motor | 550 motor | |||

| Motor power(W) | 370 | 750 | 750 | 1500 | 1500 | 3000 |

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

UK

UK

HU

HU

TH

TH

TR

TR

GA

GA

BE

BE

BN

BN