An azeotropic distillation column is a big thing that we use to make stuff. It’s a giant donjon that splits liquids into components. This process is known as distillation. Azeotropic distillation columns are very important in the production of, say, medicines, perfumes and … medicines, and even some foods.

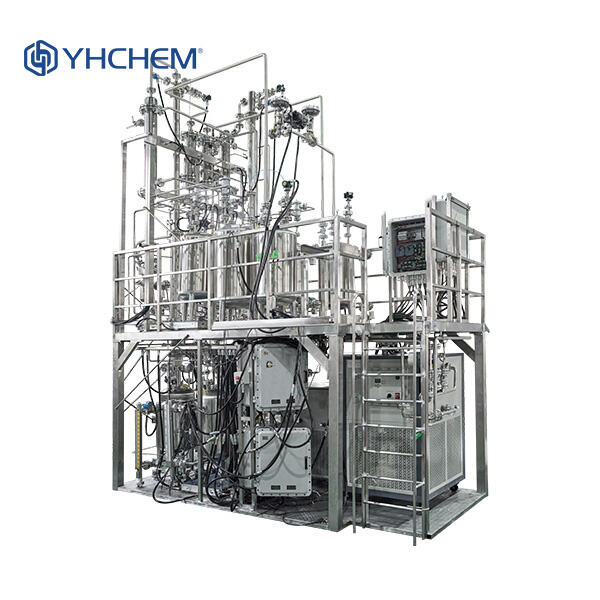

An azeotropic distillation column is the name of a special machine that allows us to separate liquids. It’s like a tall building with many floors inside. And when we feed a combination of liquids into the column and heat, the liquids begin to separate. That’s because every liquid has a unique boiling point. The NOx remains behind the liquid with the greatest boiling point (and goes up the column last). So that is how we can separate the liquids and obtain what we want.

It's all about boiling points for azeotropic distillation. Each liquid’s boiling point is different. When we heat a liquid mixture in our distillation column, the liquid with the lowest boiling point will become a vapor first. This vapor flows to the top of the column and cools, becoming liquid again. This goes on and on, until we've separated all of the liquids in the mix.

The technique may be utilized in any industry in which azeotropic distillation columns are used to produce various products. In the pharmaceutical industry, these columns are used to separate medicines into the pure form. In the perfume industry, they blend various odors. And in the food sector as well: azeotropic distillation columns are employed to extract flavors and fragrances from natural sources. “These columns are very important because they help us to isolate pure substances that we use in the construction of products.

In some cases, azeotropic distillation columns may not perform effectively. There are various reasons for this. One frequent problem is that the column is too warm. If it’s too warm or too cool the liquids may not separate properly. It would be another problem if the column is clogged with impurities. That can have an impact on how well the liquids split. To correct these issues, we must constantly monitor the temperature and column cleanliness.

To help to smoothen the operations of the azeotropic distillation, it is important to take care of the column and follow the proper steps. The rear column is open to the outside and periodic cleaning of this passage can avoid clogging and keep everything humming along smoothly. You can also check and adjust temperature if necessary. To that end, it’s important to use good materials and follow safety rules to make sure distillation does its job and gives us the results we want.