Safe and Efficient Chemical Production Though Innovation

Ammonia is a key ingredient when producing fertilisers, medicines and other industrial products. But the ways ammonia is made can be costly and hazardous to both get it out of the Earth, as well in how they liberate it. Enter the ammonia reactor, a modern-day innovation designed to produce ammonia in an effective and safe manner. Today I am going to tell you about the advantages and some of the uses for an ammonia reactor as well a few main norms that it should meet when considering buying one.

Ammonia reactors are specially designed to facilitate the process of ammonia synthesis, involved in the combination of nitrogen and hydrogen under high pressure and temperature. Ammonia Reactor - Benefits The key benefits of an ammonia reactor are :

Higher production time and lesser cost - this is also one of the benefits when you use an ammonia reactor as it can help generate massive amounts of ammonia in a much faster speed.

Safety - The conventional methods of ammonia production employ toxic and flammable chemicals that endanger workers in the lab, as well as pose risks to environmental protection. Ammonia reactors differ from the HTC unit in another sense as well-the catalysts and materials are much safer, less toxic.

Environmental benefits - Compared to traditional manufacturing, the environmental footprint of ammonia reactors is smaller: they require less energy and release fewer contaminants into the atmosphere.

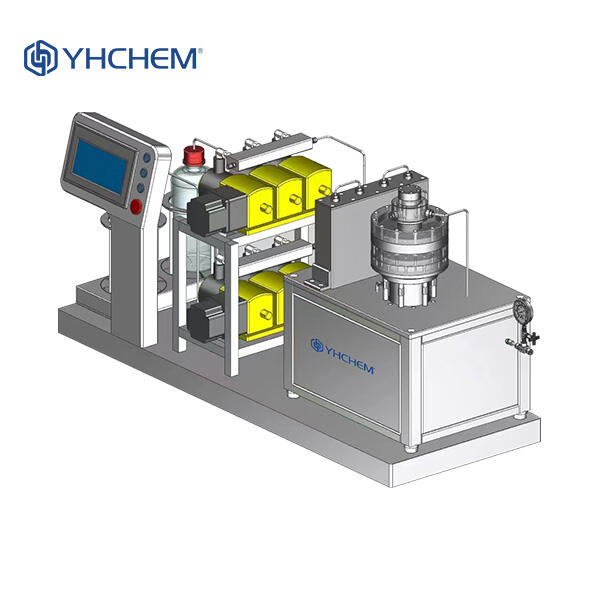

The appearance of ammonia reactors is a breakthrough in the field of chemical production. Until now, ammonia synthesis required a high-powered reactor vessel that was prone to corrosion and breakdowns. By contrast, the solid-state catalysts and construction materials of ammonia reactors to be safer as well as far more durable and efficient.

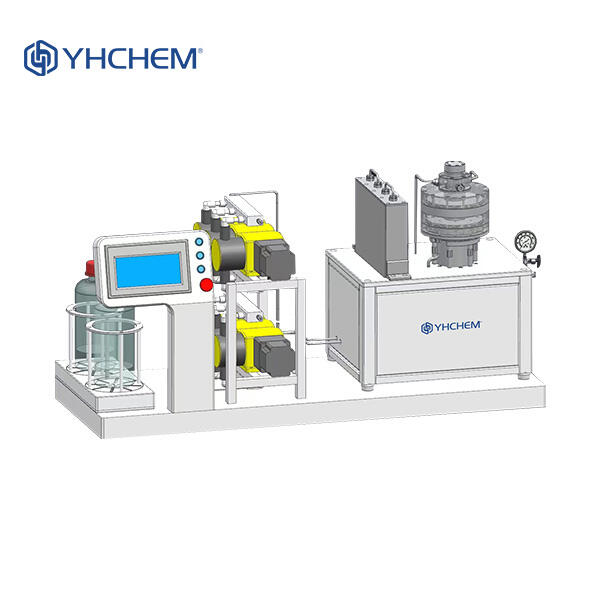

One of these innovations includes the use of automation and control systems in ammonia reactors, which allow data on the production process to be tracked immediately and controlled when needed. Thus enforcing uniform quality and reducing chances of errors or accidents.

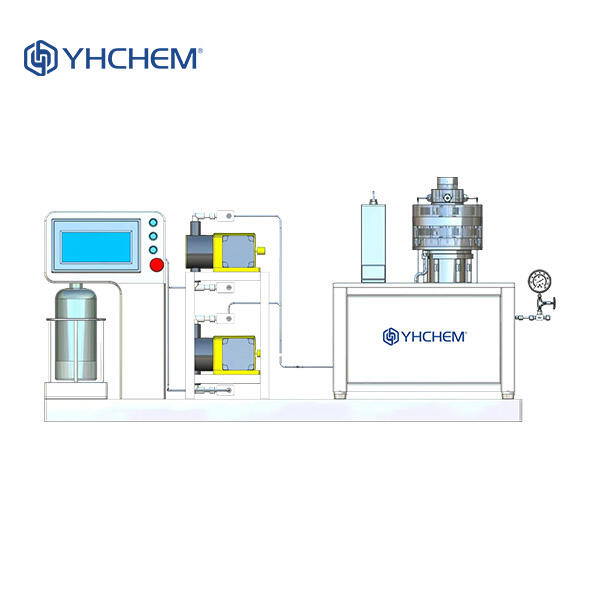

Safety is one of the most important aspect when handling dangerous chemicals; hence, ammonia reactors are intricately designed. An ammonia reactor should be fitted with safety devices like pressure relief valves and automatic shutdown in case of an emergency to ensure safe operation. In addition, operators will need to wear appropriate personal protective equipment as well as being trained in reactor handling.

The steps to perform before running an ammonia reactor include - catalyst loading, system purge and reaction initiation. It is important to follow the manufacturer's instructions and safety protocols faithfully, so as not to cause accidents or affect performance.

Buying an ammonia reactor is no small thing which means that the product needs to be perfect for you in every way possible. It is essential for the buyers to look out if they are following industry standards such as ISO 9001, and in case of UK -ISO 14001 which assures Quality Management & Environmental Responsibility.

In addition, manufacturers must provide full service and support, including installation, training/maintenance, troubleshooting. A good manufacturer will also offer you guarantees and technical assistance, as so your ammonia reactor is working correctly under the best conditions.

We are a world pioneer technological innovation, R and D and technology upgrades. We continuously introduce international advanced technologies while continuously conducting independent innovations technological improvements. We have established joint labs in conjunction with research institutes like Shanghai Chemical Industry Ammonia reactor Institute and East China University Science and Technology. These laboratories are committed providing customers most competitive solutions and products.

As a company has been listed successfully have a stable financial support Ammonia reactor development capability. We will adhere the market-driven philosophy and continue push product innovation to create worth for our customers and employees.

We Ammonia reactor range of products that include glassware well as temperature control, reactions and distillation equipment. Our product line made to meet the demands of various industries. With number of services stations, We offer our customers scientific single-stop services and products that provide prompt technical support after-sales throughout the entire usage process.

Our products assisted Ammonia reactor well-known corporations across more than 100 countries regions across globe, earning wide recognition and trust. We committed to enhancing our products and services in response to feedback from customers.

Ammonium Reactor The application areas of the ammonium reactor are diverse and include:

Fertilizer production - ammonia is important for nitrogen fertilizer, and using ammonia reactors aid in the processing of its manufacture to save time and money.

Pharmaceutical production - Ammonia is used in the industry for manufacturing of a number of pharmaceuticals as ammonia reactors operate under high oxidation states ensuring good quality with minimal impurity levels and chances on contaminations.

Industrial processes: Ammonia is used in various industrial plant operation such as refrigeration, water treatment and metallurgy. Ammonia reactors can be implemented to improve efficiency, and lower some costs involved in these processes.