Chapter 1: Background and Requirements 1.1 Introduction to Phenolic Resin Phenolic Resin, scientifically known as phenol-formaldehyde resin, is one of the earliest industrialized synthetic resins in the world, formed by polycondensation of phenolic c...

Share

1.1 Introduction to Phenolic Resin

Phenolic Resin, scientifically known as phenol-formaldehyde resin, is one of the earliest industrialized synthetic resins in the world, formed by polycondensation of phenolic compounds and formaldehyde under catalyst action. Due to its excellent heat resistance, flame retardancy, mechanical strength and electrical insulation, it is widely used in:

• Electronic materials:Photoresist Resin、PCB Substrate、Semiconductor Encapsulation

• Composite Materials: Glass fiber reinforced materials, friction materials (brake pads)

• Coatings and Adhesives: High-temperature resistant coatings, wood adhesives

• Refractory Materials: Fire bricks, insulation materials

• Engineering Plastics: Electrical switches, automotive components

1.2 Market Demand for High-Purity Phenolic Resin

With the rapid development of the electronic information industry and new energy materials, higher purity requirements have been placed on phenolic resins:

|

Application Field |

Purity Requirement |

Key Impurity Limits |

Market Price (10k CNY/ton) |

|

Photoresist Resin |

≥99.5% |

Free Phenol<500ppm |

6-12 |

|

Semiconductor Encapsulation |

≥99.0% |

Metal Ions<10ppm |

4-8 |

|

PCB Substrate |

≥98.5% |

Free Phenol<1000ppm |

2-5 |

|

General Industrial Grade |

≥95% |

Free Phenol<3000ppm |

1-2 |

1.3 Domestic Production Opportunities

Currently, the import dependence of high-end phenolic resins (photoresist grade, semiconductor grade) reaches 60-80%, with huge domestic substitution space. Domestic production has the following advantages:

• Cost Advantage: Local production costs 30-50% lower than imports

• Delivery Advantage: No need for long-term international logistics, delivery within 1 week

• Service Advantage: Localized technical support, rapid response to customer needs

• Supply Chain Security: Avoid supply disruption risks from international trade friction

2.1 Core Quality Indicators

High-purity phenolic resin needs to meet the following key indicators:

|

Item |

Photoresist Grade |

Semiconductor packaging level |

PCB Grade |

|

Molecular weight(Mw) |

3,000-8,000 |

5,000-12,000 |

8,000-20,000 |

|

PolydispersityPDI |

1.3-1.8 |

1.5-2.0 |

1.8-2.5 |

|

Softening point(℃) |

90-130 |

100-140 |

110-150 |

|

Hydroxyl content(%) |

15-25 |

12-20 |

10-18 |

|

Free Phenol(ppm) |

<500 |

<1,000 |

❤️<3,000 |

|

Free formaldehyde(ppm) |

<200 |

<500 |

<1,000 |

|

Ash Content(ppm) |

<50 |

<100 |

<300 |

|

Metal Ions(ppb) |

<10 |

<20 |

<50 |

|

Chlorine Ions(ppm) |

<20 |

<50 |

<100 |

|

Color(Gardner) |

❤️<3 |

<4 |

<5 |

|

Moisture(%) |

<0.5 |

<1.0 |

<2.0 |

2.2 Main Challenges in Purification

3.1 Method 1: Water Washing + Neutralization

【Process Flow】 Resin Solution → Hot Water Washing → Alkali Neutralization → Standing Layering → Dehydration

|

Advantages |

limitation |

|

✓Low cost, simple operation |

✗Free phenol removal rate < 60% |

|

✓Can remove some water-soluble impurities |

✗Poor removal of metal ions |

|

✓Suitable for industrial-grade products |

✗Generates a large amount of wastewater (significant environmental pressure) |

3.2 Method 2: Solvent Extraction

【Process Flow】 Resin Dissolved in Organic Solvent → Adding Poor Solvent Precipitation → Filtration → Vacuum Drying

|

Advantages |

Limitations |

|

✓ Can remove low molecular weight components |

✗ High solvent consumption (5-10 times the resin mass) |

|

✓ Allows for some degree of PDI adjustment |

✗ High solvent recovery costs |

|

✓ Suitable for small-batch, high-end products |

✗ Low yield (70-85%) |

3.3 Method 3: Conventional Vacuum Distillation

【Process Flow】 Resin Melting → Reduced Pressure Distillation (0.1-1 kPa) → Collecting Fractions

|

Advantages |

Limitations: |

|

✓ Effectively removes free phenols and formaldehyde |

✗ Requires high temperatures (180-250℃), leading to easy polymerization/degradation of the resin. |

|

✓ No solvent residue |

✗ Long residence time (2-6 hours), resulting in color darkening. |

|

✓ Recyclable monomers |

✗ High viscosity, leading to low mass transfer efficiency. |

3.4 Comparison Summary of Traditional Methods

|

Methods: |

Free phenol removal rate |

PDI control |

Yield |

Color |

Cost |

Applicable Grades: |

|

Water washing + neutralization |

50-60% |

✗ |

90-95% |

Deterioration |

Low |

Industrial Grade |

|

Solvent extraction |

70-85% |

✓ |

70-85% |

Improvement |

High |

Electronic Grade |

|

Conventional vacuum distillation |

80-90% |

✗ |

75-88% |

Severe Deterioration |

Medium |

PCB Grade |

|

Short-path molecular distillation |

95-99% |

✓ Precise |

88-95% |

Excellent |

Medium |

Photoresist Grade |

Obviously, traditional methods have significant shortcomings in high purity, low color, and precise molecular weight control, unable to meet the requirements of photoresist-grade and semiconductor encapsulation-grade phenolic resins.

4.1 Core Technology: Short Path Molecular Distillation

Yuanhuai YHCHEM Molecular Distillation System is a special liquid-liquid separation technology that achieves separation under high vacuum and low temperature conditions by utilizing differences in the mean free path of different substance molecules, particularly suitable for purification of heat-sensitive, high-viscosity, and high-boiling-point materials.

4.2 Working Principle

|

Steps: |

Process Description |

Key Parameters |

|

① Material feeding |

The preheated resin solution enters the evaporator. |

Fluidity: Good |

|

② Film formation |

A scraper spreads the material into a thin film. |

Rotation Speed: 10-300 rpm |

|

③ Heating |

The heating surface is maintained at a relatively low temperature. |

Pressure: Much lower than conventional distillation |

|

④ Evaporation |

Light components (low boiling point) evaporate and escape. |

Mean Free Path: >2-5 cm |

|

⑤ Short-distance transport |

The evaporated molecules travel in a straight line to the condensing surface. |

Distance: 2-5 cm, no collisions |

|

⑥ Condensation |

The light components condense on the condensing surface. |

Temperature: -10~20℃ |

|

⑦ Separation |

The heavy components flow down along the heating surface. |

Unvaporized High Molecular Weight Substances |

|

⑧ Collection |

The light and heavy components are collected separately. |

Continuous segmented operation |

4.3 Unique Advantages for Phenolic Resin Purification

|

Technical Features: |

Significance for phenolic resins: |

|

Ultra-high vacuum |

Boiling point reduced by 80-150℃, preventing thermal polymerization/degradation |

|

Extremely short residence time |

2-30 seconds, no color degradation, maintaining transparent light yellow color |

|

Low-temperature operation |

80-180℃, protecting heat-sensitive hydroxyl groups and ether bonds |

|

Continuous segmented collection |

Precise separation of oligomers, medium polymers, and high polymers, controlling PDI |

|

Wiped-film design |

Uniform film formation of high-viscosity resins, high mass transfer efficiency |

|

All material contact surfaces made of 316L stainless steel |

Eliminates metal ion contamination |

(1) Core Distillation Unit

|

Components |

Specifications/Materials |

Features: |

|

Evaporation area |

0.1-10 m² |

Customizable, with processing capacity of 5-500 kg/h |

|

Scraper |

PTFE/316L |

Rotation speed of 10-300 rpm, forming a 0.1-1 mm thin film |

|

Heating method |

Thermal oil/Electric heating |

Temperature control accuracy of ±2℃ |

|

Condenser |

316L stainless steel |

Built-in spiral tube, -10 to 20℃ |

|

Material |

All 316L stainless steel + PTFE seal |

Corrosion-resistant, low metal ion contamination |

(2) Vacuum System

• Roots Pump + Rotary Vane Pump Combination: Ultimate vacuum 0.1 Pa

• Vacuum Gauge: Capacitance diaphragm vacuum gauge, accuracy 0.1 Pa

• Cold Trap: -80°C, protecting vacuum pump, recovering monomers

(3) Automation Control System

• PLC + Touch Screen: Siemens/Mitsubishi

• Real-time monitoring: temperature, vacuum level, feed rate, rotation speed

• Data Recording: Historical curves, batch traceability

• Alarm Protection: Over-temperature, vacuum abnormality, liquid level abnormality automatic shutdown

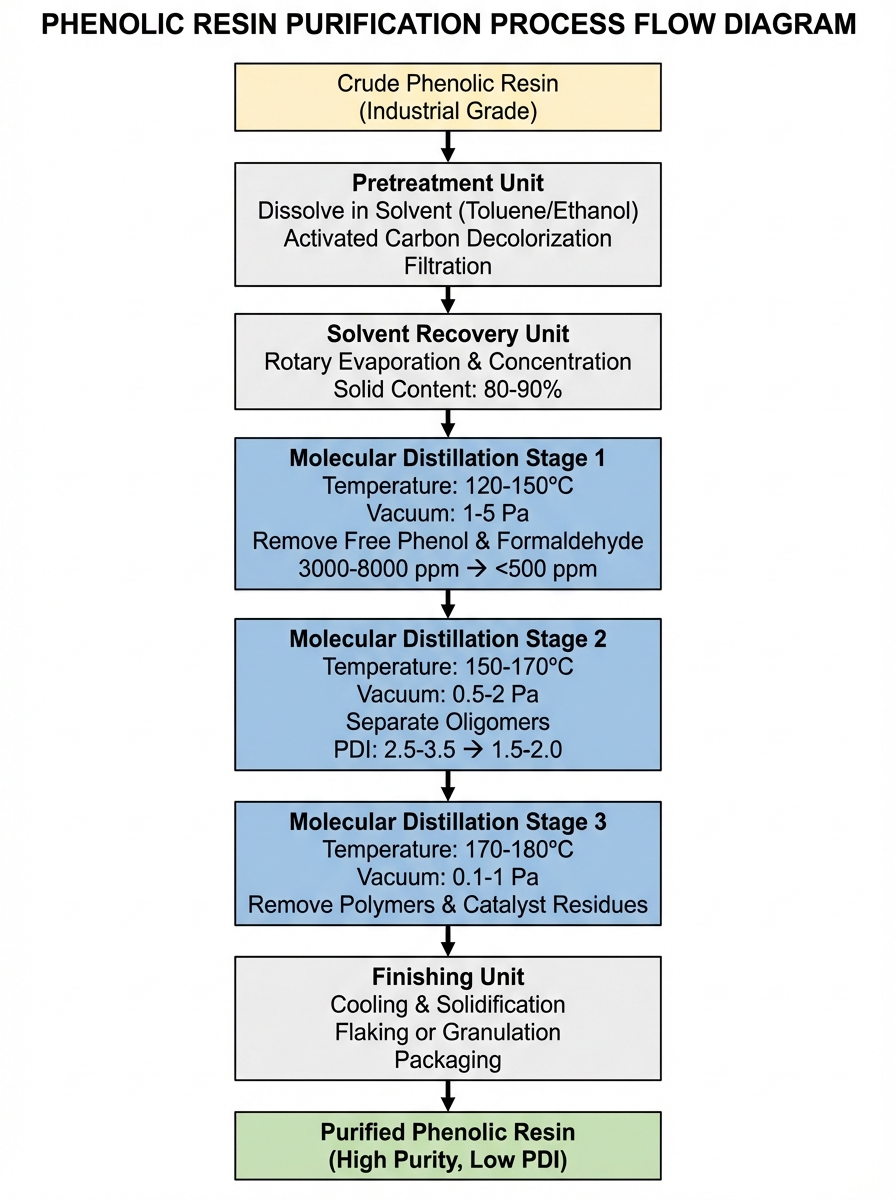

6.1 Complete Process Flow

6.2 Key Process Parameters

First Stage Distillation (Remove Light Components)

|

Parameters: |

Set values: |

Objective: |

|

Feed temperature |

60-80℃ |

To reduce viscosity for easier transportation |

|

Evaporation temperature |

120-150℃ |

To vaporize free phenol (boiling point 181℃) |

|

Vacuum level |

1-5 Pa |

To lower the boiling point to 80-120℃ |

|

Wiper speed |

150-250 rpm |

To form a uniform thin film |

|

Feed rate |

10-30 kg/h·m² |

Residence time: 5-15 seconds |

|

Collected components |

Light components (free phenol, formaldehyde, water) |

5-15% |

Effect: Free phenol reduced from 3000-8000 ppm to <500 ppm

Second Stage Distillation (Adjust Molecular Weight Distribution)

|

Parameters: |

Settings: |

Objective: |

|

Evaporation temperature |

150-170℃ |

Vaporization of oligomers (Mw < 2000) |

|

Vacuum level |

0.5-2 Pa |

Lower boiling point |

|

Wiper speed |

100-200 rpm |

Balanced mass transfer and residence time |

|

Feed rate |

8-20 kg/h·m² |

Residence time: 10-30 seconds |

|

Collected components |

Light components (oligomers) |

10-20% |

Effect: PDI narrowed from 2.5-3.5 to 1.5-2.0

Third Stage Distillation (Refining)

|

Parameters: |

Settings: |

Purpose: |

|

Evaporation temperature |

170-180℃ |

Removal of catalysts and pigments |

|

Vacuum level |

0.1-1 Pa |

Extreme vacuum |

|

Wiper speed |

80-150 rpm |

Fine separation |

|

Feed rate |

5-15 kg/h·m² |

Thorough contact |

|

Collected components |

Intermediate distillate (target product) |

70-85% |

Effect: Purity >99.0%, metal ions (combined with ion exchange) <10 ppb

6.3 Material Balance Example

Example based on 100 kg crude resin:

|

Process Stages |

Material Type |

Mass (kg) |

Proportion of raw materials used |

Material Disposition |

|

Feeding |

Crude Phenolic Resin |

100 |

100% |

Raw materials |

|

Pre-treatment |

Solvent Loss, Filtration Residue |

2-3 |

2-3% |

Solvents are recyclable |

|

First Distillation |

Light Components (Free Phenol, Formaldehyde, etc.) |

8-12 |

8-12% |

Can be resourcefully utilized |

|

Second Distillation |

Light Components (Oligomers) |

10-15 |

10-15% |

Partially reusable |

|

Third Distillation |

Heavy Components (Polymers, Impurities) |

3-5 |

3-5% |

Discarded or downgraded for other uses |

|

Output |

High-Purity Phenolic Resin |

70-80 |

70-80% |

Electronic grade/photolithography grade products |

【Total Yield】70-80% 【Purity Enhancement】95% → 99%+

7.1 Comparison with Traditional Methods

|

Indicators: |

Traditional Vacuum Distillation |

Solvent extraction |

YHChem Molecular Distillation |

|

Operating temperature |

180-250℃ |

Room temperature - 60℃ |

80-180℃ |

|

Residence time |

2-6 hours |

Several hours |

10-60 seconds |

|

Vacuum level |

0.1-1 kPa |

Atmospheric pressure |

0.1-10 Pa |

|

Free phenol removal rate |

80-90% |

70-85% |

95-99% |

|

PDI control |

✗ |

✓ |

Precise |

|

Color change |

Degradation: 3-5 levels |

Improved by 1-2 levels |

No degradation |

|

Yield |

75-88% |

70-85% |

88-95% |

|

Solvent consumption |

None |

5-10 times |

None |

|

Energy consumption (kWh/ton) |

800-1200 |

300-500 (including recovery) |

400-600 |

|

Equipment fouling |

Severe |

None |

Slight |

|

Metal ion control |

Moderate |

Poor |

Excellent (All 316L) |

|

Continuous production |

Difficult |

Difficult |

Supported |

7.2 Core Advantages Summary

✓ Ultra-high Purity - Free phenol <500 ppm, free formaldehyde <200 ppm, meeting photoresist-grade requirements

✓ Precise Molecular Weight Control - PDI adjustable to 1.3-1.8, adaptable to different applications

✓ Color Retention - Light yellow transparent, no thermal degradation

✓ High Yield - 88-95%, 10-20% higher than solvent extraction

✓ Environmentally Friendly Zero Emission - No wastewater, no waste solvent, compliant with environmental policies

✓ Continuous Production - High degree of automation, low labor costs

✓ Long Equipment Life - 316L stainless steel, corrosion resistant, easy to clean

Photoresist-Grade Phenolic Resin Purification

Customer: An electronic chemicals company (Pearl River Delta region)

Raw Material: Industrial-grade phenolic resin (95% purity, 5000 ppm free phenol)

Target: Photoresist grade (purity ≥99.5%, free phenol <500 ppm, PDI 1.5-1.8)

Process Parameters:

• Equipment: YMD-150

• Three-stage distillation, temperatures 120/150/170℃

• Vacuum level: 5/2/0.5 Pa

• Total processing time: Approximately 40 seconds

【Purification Effect Comparison】

|

Specifications |

raw material |

After one distillation |

After two stages of distillation |

Finished product |

Target |

|

Purity (%) |

95.0 |

97.5 |

98.8 |

99.6 |

≥99.5 |

|

Free Phenol (ppm) |

5000 |

800 |

350 |

<200 |

<500 |

|

Free Formaldehyde (ppm) |

800 |

200 |

80 |

<100 |

<200 |

|

PDI |

2.8 |

2.6 |

1.9 |

1.6 |

1.5-1.8 |

|

Softening Point (°C) |

105 |

108 |

112 |

115 |

110-120 |

|

Color (Gardner) |

5 |

4 |

3 |

<3 |

<3 |

|

Ash Content (ppm) |

300 |

150 |

80 |

<50 |

<50 |

|

Metal Ions (ppb) |

80 |

50 |

20 |

<10 |

<10 |

Economic Benefits: Yield: 92%

Cost and Revenue per Ton:

• Raw Material Cost: 20,000 CNY/ton

• Purified Selling Price: 80,000 CNY/ton

• Gross Profit per Ton: 60,000 CNY

Annual Production of 200 Tons Benefits:

• Annual Profit Increase: 12 million CNY

Appendix A Testing standards for photoresist-grade phenolic resins

|

Test Items: |

Standard methods: |

Instruments and Equipment: |

|

Molecular weight |

GPC |

Waters GPC, standard polystyrene |

|

Hydroxyl content |

Chemical titration |

Potentiometric titrator |

|

Softening point |

GB/T 4507 |

Ring and ball softening point apparatus |

|

Free phenol |

GC-FID |

Gas chromatograph |

|

Free formaldehyde |

HPLC |

High-performance liquid chromatograph |

|

Metal ions |

ICP-MS |

Inductively coupled plasma mass spectrometer |

|

Ash content |

GB/T 9345 |

Muffle furnace, 550℃ incineration |

|

Color |

Gardner method |

Colorimeter |

|

Moisture content |

Karl Fischer |

Karl Fischer moisture titrator |

Appendix B: Frequently Asked Questions (FAQ)

Q1: Can molecular distillation be used to process solid phenolic resins?

A: Yes. It needs to be dissolved in a solvent (such as toluene, ethanol) or heated to a molten state (usually 80-120°C) before feeding.

Q2: Does the equipment require special explosion-proof requirements?

A: If flammable solvents (such as toluene, ethanol) are used, explosion-proof areas (such as Zone 2) need to be classified, equipped with explosion-proof motors and instruments.

Q3: Can thermosetting phenolic resins be processed?

A: We recommend processing thermoplastic (Novolac) type resins. Thermosetting (Resol) type resins are not suitable for molecular distillation due to their poor fluidity caused by partial cross-linking. If processing is necessary, it must be done in the liquid phase before curing.

Q4: How to store the purified resin?

A: It is recommended to store the product in a sealed container in a cool, dry place to prevent moisture absorption and oxidation. For photoresist-grade resins, storage under nitrogen protection is recommended, and the shelf life can reach 12 months.

Q5: How long does a single equipment cleaning take?

A: Approximately 2-4 hours. The process involves circulating solvents such as toluene or acetone, and the effect is enhanced by heating to 80-100℃. It is recommended to perform a thorough cleaning after every 10-20 batches.

Q6: Equipment footprint and height requirements?

A: YHMD-150 occupies approximately 15 m², equipment height approximately 3.5 meters, requires factory floor height ≥ 4.5 meters. If floor height is insufficient, horizontal structure can be customized.

Q7: Can multiple different grades of resin be processed simultaneously?

A: Yes, but cleaning is required between different batches to avoid cross-contamination. It is recommended to establish a product switching SOP to ensure batch-to-batch consistency.