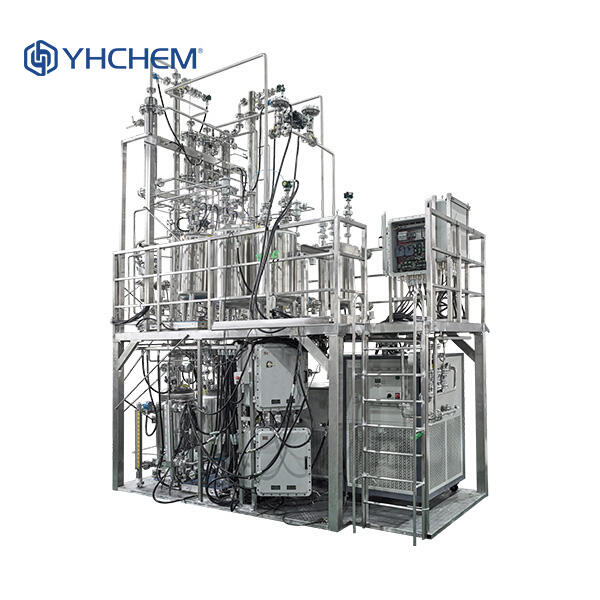

Stainless steel distillation columns are tools and instruments for various applications such as for example the industrieums, mixtures are separated by distillation in separate components. These are made of heavy-duty stainless steel, so they’ll last and last. Here’s just a few of the primary advantages of utilizing Stainless Steel Distillation Column Towers in several industrial applications.

Another major strength of stainless steel distillation columns is the effectiveness they have in separating mixtures. These columns are used to separate different components according to their boiling points. As the column heats the mixture, the components with lower boiling points become gas first and rise to the top. There, they are gathered and reverted to liquid. It is for this reason that this process is instrumental in splitting apart various components with precision, proving that stainless steel distillation columns are extremely important in fields such as medicine, oil processing meets food processing.

*Stainless steel is a very durable and sturdy metal that will last for a long time, so it will make an excellent still for distilling. It's not even likely to get damaged by high temperatures and pressures. This quality enables the columns to work powerfully for a prolonged time. — and stainless steel doesn’t rust, which matters in spots with harsh chemicals. This can make the stainless steel distillation column the preferred choice for industries interested in long-lasting services.

And stainless steel distillation columns can cope with extremely high heat and harsh chemical environments. They are designed to withstand heat in the distillation process and won’t break down or stop functioning. Because it will not rust, the columns will continue to be sturdy and perform as they should even with corrosive materials. By using these types of still columns makes stainless steel distillation columns a more safer choice for industrial that require precision and durability.

Distillation process is precisely controlled by using stainless steel distilling columns. This allows industries to make very pure products with ease. The columns are designed to be temperature-, pressure- and flowrate-adjustable, so the operators can control the separation more precisely. This operation enables the final product to be pure without any unintended materials in the product. Fields such as medical and chemical processing rely on stainless steel distillation columns to produce high-quality products with each use.

Stainless Steel Distillation Columns can be used in a number of industries for a multitude of jobs. They can isolate components of a mixture or reactants and purify a compound, so are a versatile system for various applications. There are other industries, like medical, food processing or oil, and they use stainless steel distillation columns as it is a good way to get good results. Their flexibility and resiliency make them useful in a variety of industrial applications in which precision, strength, and/or purity are key.