Flow Reactor: These instruments are a special help in chemical reactions. They are becoming increasingly popular with scientists as they offer many advantages over conventional reactors. But these machines have a variety of applications. In the following, we will learn more about why they are great and how to use them in different applications.

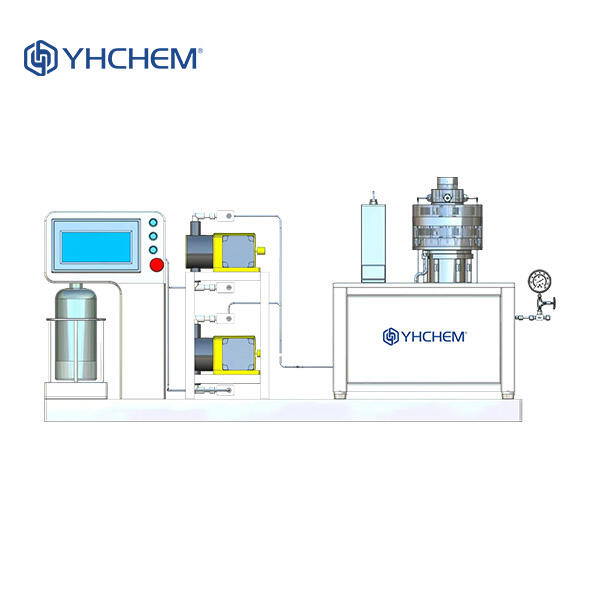

An extraordinary aspect of flow reactors is that they give influence over the procedures occurring in them. Chemicals can be added in a stepwise fashion, as researchers adjust temperature and pressure on the fly to obtain their desired results In addition, the flow reactor themselves can easily be scaled and also a same amount of reaction needs just smaller reactors when it comes to small laboratory up through larger industrial scales. This flexibility not only saves time and costs, but will significantly ease the development of chemical production to large-scale implementation.

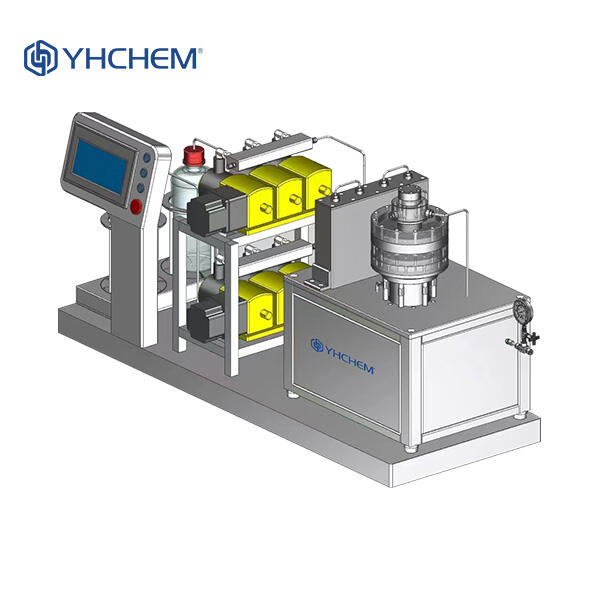

The field of flow-reactors is continuously changing with all sorts new ideas coming and going. It would allow us to do things like scale reactions down even further by using miniature reactors suitable for the small-scale of many chemical experiments. Moreover, computer modeling for flow process optimization in flow reactors changed the field. The automation of reaction conditions simulation and prediction makes the production process more efficient, which is helpful for the management of other resources scientists have.

Flow reactors offer improved safety attributes over conventional batch reactors. Introducing chemicals slowly can help to prevent accidents, and the enclosed environment of a reactor contains reactions that may involve exposure to dangerous substances Moreover, flow reactors isolate and protect their environment better because they work within a closed system so chances of contamination are decreased; helping produce the high purity chemicals necessary in industries like pharmaceuticals or electronics.

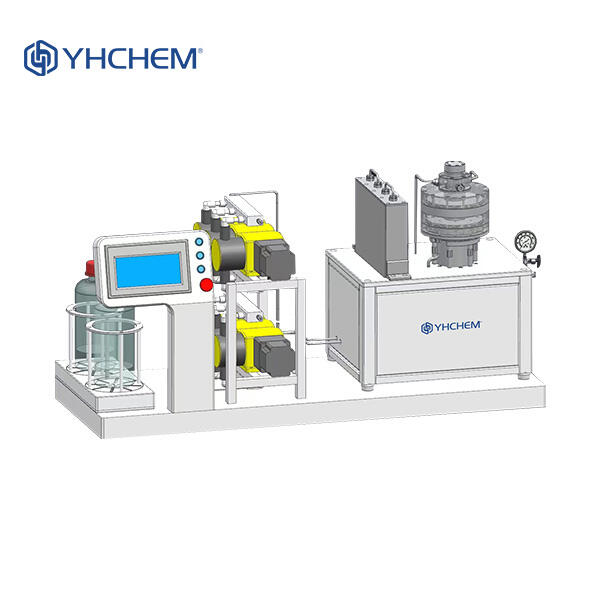

Flow reactors are widespread and are applicable in multiple fields; even so far, industries such as pharmaceuticals to materials science have been examining the utilization of microreactor systems. It can be used in oxidative, reductive, alkylative and polymeric reactions. Control over temperature and pressure among other factors are essential to the successful use of flow reactors. The ultimate output is collected at the end of Reaction Zone and it can be processed, purified as per requirement.

We provide range of products, Flow reactor chemistry glassware well as temperature control, instrumentation for reaction and distillation. Our range products is made to meet the demands different industries. With multiple service supply stations, We offer customers scientific one-stop products and services that provide prompt technical support and support after-sales throughout the entire usage process.

We have strong financial foundation and long-lasting capacity for Flow reactor chemistry a publicly traded company. We will remain committed principles that are based on market demand, driving continuous product innovation technological advancement to create greater value and more opportunities for customers, investors, and employees.

We are a world pioneer technological innovation, R and D and technology upgrades. We continuously introduce international advanced technologies while continuously conducting independent innovations technological improvements. We have established joint labs in conjunction with research institutes like Shanghai Chemical Industry Flow reactor chemistry Institute and East China University Science and Technology. These laboratories are committed providing customers most competitive solutions and products.

We've supplied products thousands of reputable companies over 100 Flow reactor chemistry we have gained a wide amount of appreciation trust. We're committed improving our products and services according to the feedback our customers.

One of the main things to consider when purchasing flow reactors is that you purchase it from a reputable supplier. Top-quality equipment and ingredients are of course essential, as well as suppliers who provide technical maintenance and support. The consideration of what type flow reactor should be used, which is beyond the knowledge scope and relates to other aspects such as installation, training for personnel's assistance, warranty policy in case quickly materialize prohibit sustain efficient/safety uses. Flow reactors are among the most innovative and effective methods used across a wide range of fields, providing significant benefits compared to standard methodologies. Choosing a high-quality supplier and provided services is crucial to ensure that you are able to get the most out of flow reactor chemistry