Yuanhuai designs and manufactures a broad portfolio of laboratory, pilot and industrial-oriented equipment systems supporting mixing, reaction, solvent recovery, concentration and purification processes. Our modular design philosophy enables flexible configuration while ensuring reliability, safety and repeatable performance. With over 15 years of experience and 10,000+ systems delivered to customers in 50+ countries, including leading research institutes, universities and industrial laboratories, we provide practical, well-engineered solutions with clearly defined scope and engineering boundaries. Yuanhuai is certified to ISO 9001, ISO 14001 and ISO 45001, with CE- and UL-compliant products, and is recognized as a National High-Tech and Specialized & Innovative Enterprise. We also collaborate with institutions such as the Chinese Academy of Sciences and East China University of Science and Technology to advance process engineering capabilities.

Since 2009

Countries and regions

Cooperative customer

Equipment systems

Yuanhuai provides modular laboratory and pilot-scale equipment platforms designed around key process steps such as mixing, reaction, concentration, separation and purification.

These process-oriented systems are applied across different industries based on specific application requirements, supporting research,

process development and pilot-scale validation rather than oversized turnkey production plants.

Thin-film distillation equipment enhances fragrance purity, prevents material deterioration, and precisely separates high-value-added products such as menthol and vanillin. It effectively addresses customer pain points in applications involving various natural extracts, including rose essential oil and sweet orange oil.

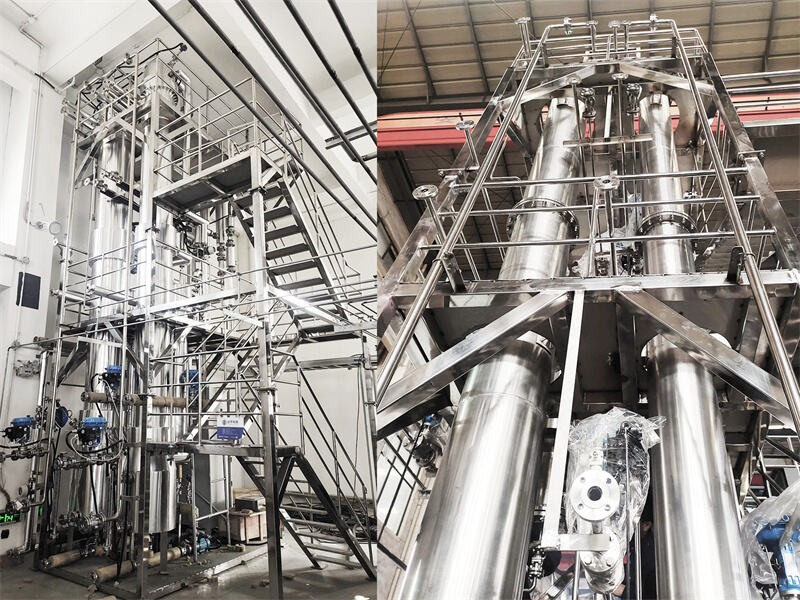

For heat-sensitive, easily oxidized, and high-boiling-point materials such as EPA, DHA, and VE, high-vacuum distillation equipment, including molecular distillation, can achieve safe and efficient purification, concentration, and separation processes.

Microreactors provide precise temperature control to meet the high-purity requirements of lithium battery materials, while molecular distillation efficiently removes impurities, overcoming the purity bottleneck of epoxy resins. Yuanhuai Equipment is here to help you achieve perfection.

To enable continuous production of hazardous reactions such as aromatic nitration and diazotization of aromatic compounds, microreactors ensure intrinsic safety and comply with national policies.

Yuanhuai Stainless Steel Equipment provides pilot-scale petrochemical separation, purification, and impurity removal solutions for glycerol wastewater recovery, sulfonated kerosene purification, and biodiesel production.

From food products like sunflower seed oil and olive oil, to food additives like capsicum and natural apple flavoring, and pesticide ingredients like herbicides and glyoxylic acid, Yuanhuai equipment can achieve efficient extraction and precise separation.

Yuanhuai designs and manufactures modular laboratory and pilot-scale equipment systems supporting key process steps such as mixing, reaction, concentration and purification.

We focus on practical engineering, clear capability boundaries and reliable equipment delivery. Rather than over-promising large turnkey plants, we work closely with customers to configure suitable equipment platforms based on real process requirements.

Discuss Your Application

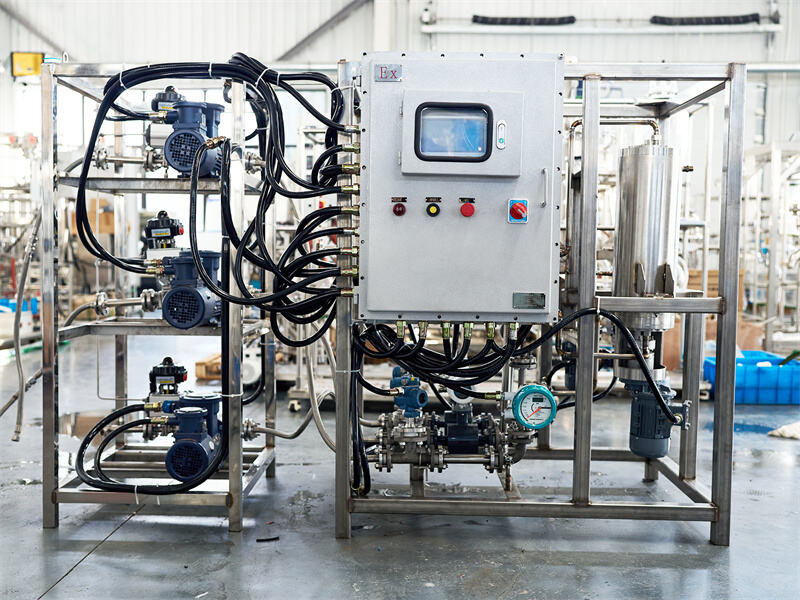

Standardized equipment modules designed to be flexibly configured for different process steps and application needs.

Process-oriented evaluation of scale, materials and operating conditions to recommend practical equipment configurations

Equipment platforms designed for laboratory research, process development and pilot-scale validation across multiple industries.

Manufactured under strict quality control, supported by technical documentation and remote assistance to reduce operational risk.

Deep-sea fish oil is a natural nutraceutical with exceptionally high nutritional value. It is rich in highly unsaturated fatty acids, most notably the omega-3 polyunsaturated fatty acids eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA). Mod...

Dec.18.25

Biopharmaceutical development is under constant pressure to shorten timelines, reduce cost, and deliver reproducible product quality. As processes transition from laboratory experiments to pilot trials and finally commercial manufacture, organization...

Dec.09.25