When do you think, how different liquids can be separated from a mixture? So the question raised was quite intriguing! Column Distillation One way to do it is column distillation. Column distillation uses boiling points (the temperature when a liquid changes from a liquid to gas) of liquids as the method for separation. The operation is very common & it helps us to have the clear liquid from mixtures.

Column distillation involves heating a blend of liquids in what is called, "a still." A still just as a pot on the stove! The liquid that boils at the lowest temperature will begin to turn into steam as we heat up this mix. This steam is similar to the hot air that escapes from a boiling pot of water. The steam, rising up the column does so in a cool part of it called condenser. A condenser is used to cool the steam and liquid back into a fluid.

This liquid then gets collected in the different container, back as a Liquid form. All the different liquids of these mixture keeps passing through this whole process. Both are at different boiling points and hence in order for one of them to form steam, we would need a particular temperature. There it is folks, column distillation for the win!!!

Column Distillation does have one positive attribute; it assimilates liquids to be more purified and safer ( Column July, 1900). It can be used to take impurities out of bad things, like water so that it is safe to drink and cook with. This is so important as clean water can mean health. Column distillation is used for making tasty beverages like whiskey and vodka. Well this drinks has an special process to be as good!

Column Distillation is an extraordinarily efficient means of liquid purification, allowing liquids with even almost identical boiling points to be separated. This makes it able to differentiate between similar liquids that are indeed different. There is plenty of room in the column for the steam to cool and condense back into a liquid. This large space helps further separate the liquids. This way, the liquids can be further gushed many times consecutively. The more you do it, the better and cleaner your liquids will be!

Next, heat the still. When the heat is applied, well as we all know anything below room temperature starts to turn into a gas so obviously you guessed it correct, liquid with lowest boiling point will start turning into steam.

So in conclusion column distillation is great method of separating liquids from mixtures by boiling. Making water to clean and tasty beverages. This is an effective method but when both liquids have close to boiling points. Column Distillation, you heat the still with mixture in it and allow to lowest boiling point liquid turn into steam cool back down into a liquid and collect.

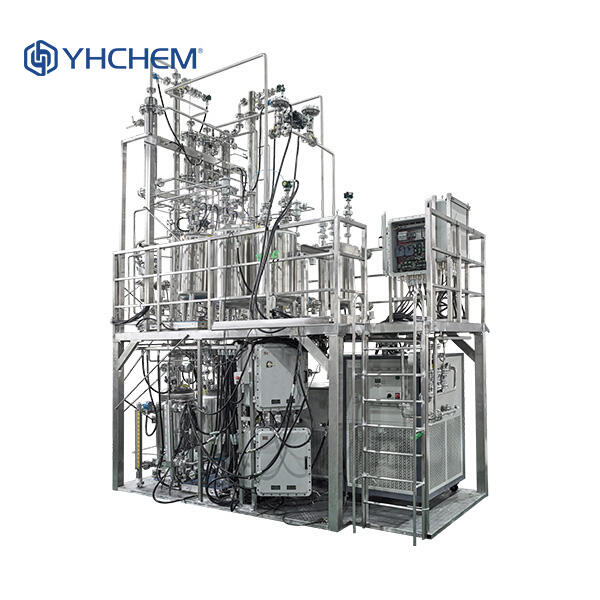

We are a global leader technological innovation, R and D and technology upgrades. We constantly introducing new technologies from around world while developing independent innovations and technological advancements. We have set up joint laboratories in conjunction with research institutes such as Shanghai Chemical Industry Research Institute East China University of Science and Technology. These labs have been established provide column distillation with the most competitive solutions and products.

Our products assisted column distillation well-known corporations across more than 100 countries regions across globe, earning wide recognition and trust. We committed to enhancing our products and services in response to feedback from customers.

As a listed company is successful, have stable column distillation sustainable growth capacity. We follow market-driven principles drive continuous product innovation to create benefits for our customers and employees.

We provide a range of products include glassware, column distillation control, distillation reaction instruments. Our product line is specifically designed to meet the needs different industries. With a variety of service supply stations, we offer customers scientific all-in-one products services that provide prompt technical support as well after-sales services throughout their use.