Wiped film distillation is a method that you’ll find everywhere in many industries. This apparatus is a giant centrifuge, a machine that whirs rapidly to divide liquids. It helps create many things we use, including medicines, perfumes and some foods. Why is short path wiped film distillation important, and how does it work?

Wiped film distillation machine is heated to make liquid become gas. Then that vapor is rapidly cooled to load it back up into a liquid. The device spins incredibly fast to separate the varying components of the liquid slurry. The heavy parts are kept on the bottom, while the light parts ascend to the top, by the spinning motion. This method is used to portion out the various components in the fluid mixture, so that they can be used for various purposes.

Advantages of Wiped Film Distillation Plant - 1 - Short Residence Time: short residence time of liquid material in evaporator can cause minimum material decomposition or loss, most of time it is only 5-10sec.

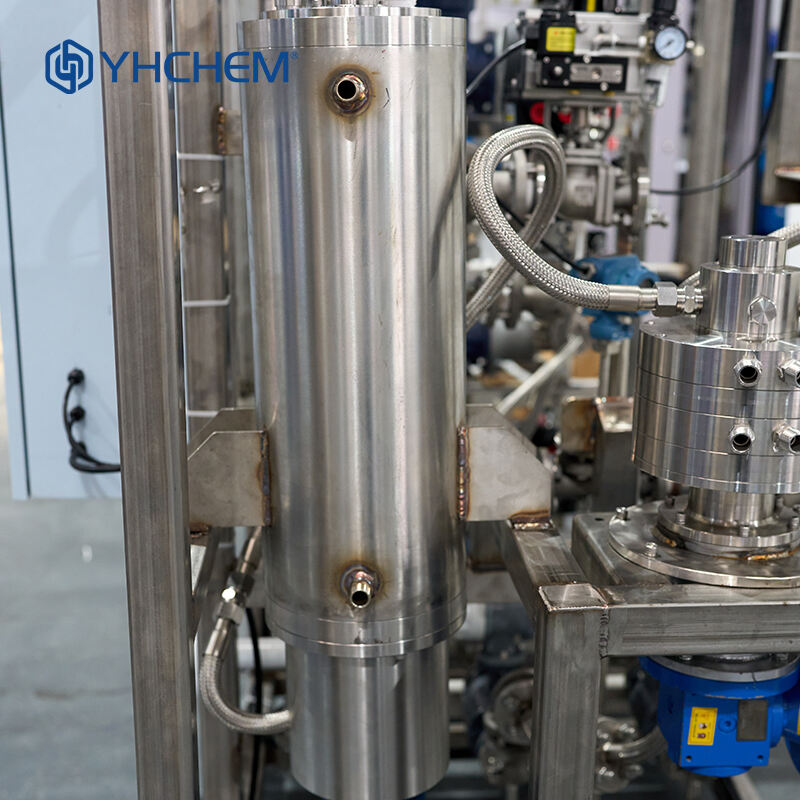

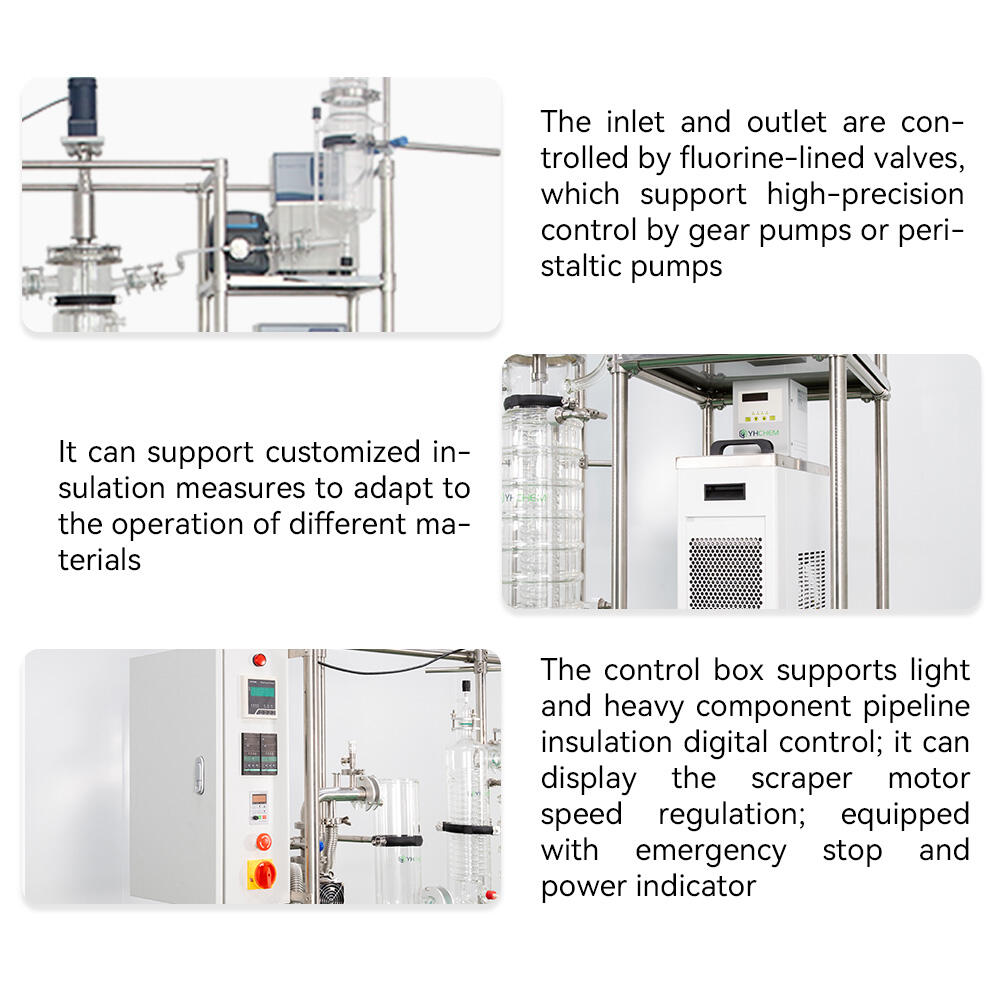

Wiped-Film Distillation Equipment is designed so that the products contact the heat transfer surface and receive the hotter temperature. One of its great features is that it can sort through materials very, very fast. This allows companies to produce more of their products in less time. Wiped film distillation apparatus also helps to make the end product highly pure, with nothing other than the actual materials required for the product to function properly.

It is crucial to use wiped film distillation equipment because it enables companies to produce high-quality products. By isolating all of those different substances in a liquid mixture, companies can ensure that their products actually work the way they’re supposed to. This is particularly crucial when it comes to industries dealing with things such as medicine or food, when a product’s quality and integrity can have an impact on the health and safety of individuals.

One important aspect of wiped film distillation system is its dynamic action. It spins, and that spinning helps to isolate substances better than other methods. It's also quick to cool it down, which helps ensure that the end product is really pure. Wiped film distillation equipment is also simple and easy to clean and maintain – which helps everyone save time and money.

Distillation equipment for wiped film process can enhance production in numerous methods. It allows companies to produce more of their products in less time by efficiently and rapidly separating substances. This can enable companies to meet increasing demand for their products, and make more money. Wiped film distillation machines also enable companies to produce higher quality products, which increases customers and a good word of mouth.

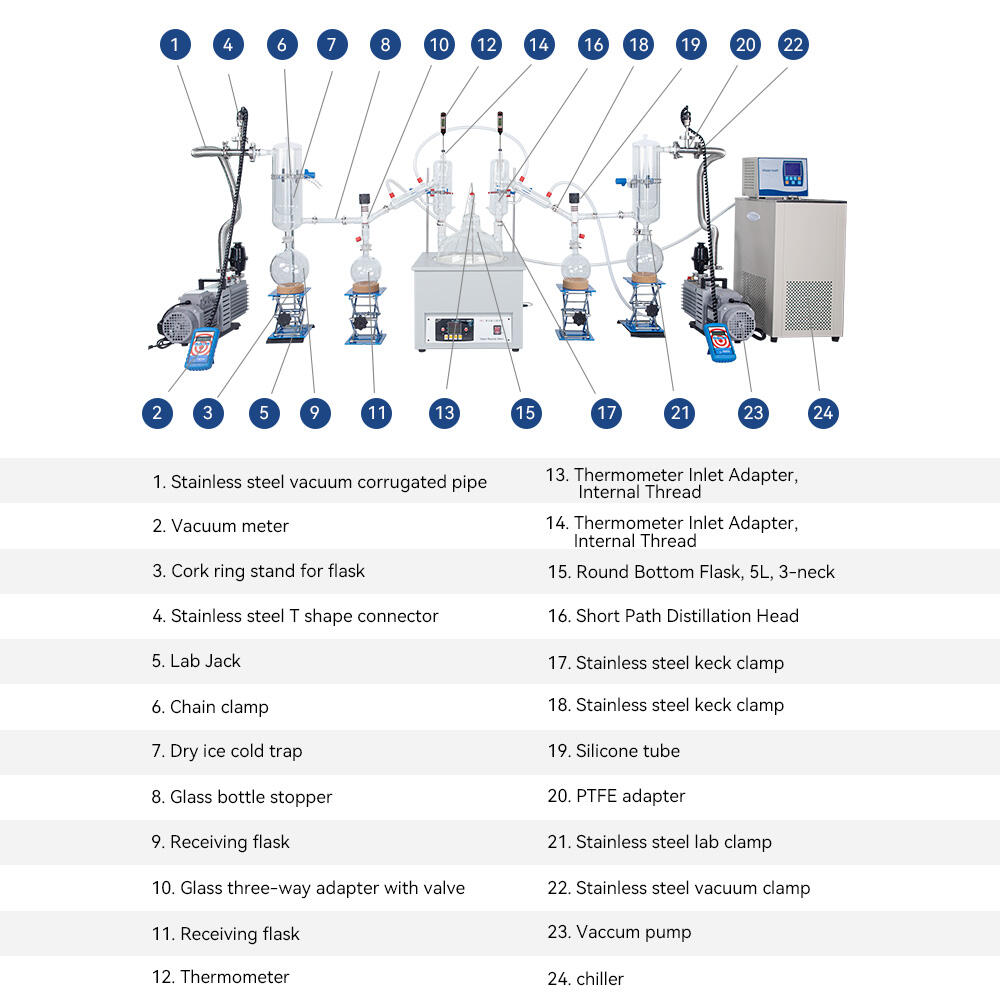

We provide range products including glassware temperature control, well reactions and wiped film distillation equipment equipment. Our product line specifically designed meet the needs of various industries. We offer customers all-in-one service that includes multiple service centers, supplying prompt technical assistance, after-sales services products.

Our products assisted hundreds of well-known companies over 100 countries and regions across globe, earning wide recognition and trust. Informed by the needs of wiped film distillation equipment demands, we continually improve our products and services. We're committed to increasing value and return on investment our customers.

We world-class technological wiped film distillation equipment and R and D capabilities across globe, constantly developing international technologies of the future conducting continuous independent technological innovation and upgrades. Through collaborations well-known research institutions like Shanghai Chemical Industry Research Institute and East China University of Science and Technology, we have established joint laboratories, focused providing clients the best competitive products and solutions.

We have solid wiped film distillation equipment structure and sustainable growth capability as a listed company. We will remain committed market demand-oriented principles drive continuous product innovation and technological advancement generate more opportunities and value for customers, investors, and employees.