Industrial distillation columns are big gadgets which can be used in the separation of one or more chemical components from a liquid mixture. Kind of like one big mixer that helps to mix and sort through the many ingredients. This YHCHEM Distillation is used in a way that manufacture important things like medicines which heal sick people and petrol etc. There are many parts inside this machine, and each part has its own work to do. For you and me, the vital factor of technology relays in how these parts work together.

They do so by utilizing heated columns to separate various chemicals. Each different chemical has a specific boiling point; this is the temperature at which it changes from liquid to gas. At the base of the column, as its chemicals are heated up they undergo a transition from liquid to gas state. As these gases rise up the column, they will cool off. The gases will then cool and re-condense back into liquids. The chemicals with higher boiling points will condense and re-condense, which means they revert into liquid again first and drop to the bottom of the column. On the other hand, substances with lower boiling points will take a greater amount of time to cool and as they condense, will move up through the column.

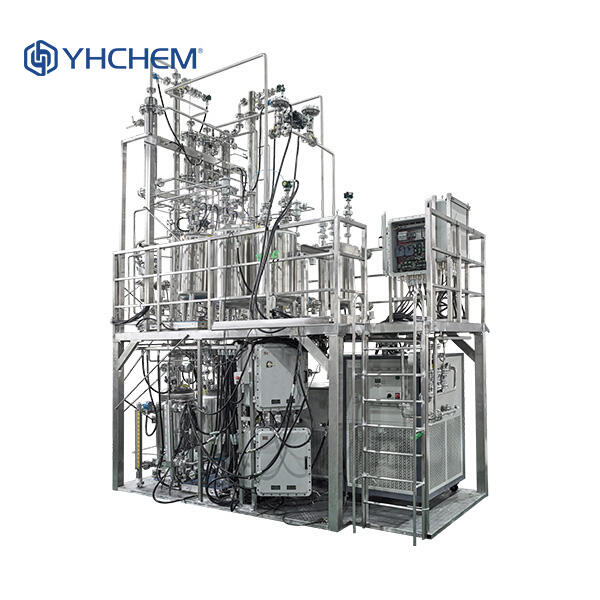

An industrial distillation column is made up of parts that all work in sync to ensure the separation goes off as planned. Becomes a bottom of the column indexed as builder. It is the area where chemicals are heated and finally converted gas. The condenser — this is the bit at the top of a column. It is here that the gases cool and reconvene to liquid form. There are special trays or packing materials in the middle of this column that increase the residence time during which individual chemicals rise and fall.

These main parts of YHCHEM Distillation Column as well as the processes that are involved in enhancing its functionality, and there. Reflux is also a major process contrary part. This occurs when some of the liquid that reached the top starts to fall down again. In other words, this helps the already greater separation of chemicals. A separate operation, side-draw is the act of pulling chemicals from multiple locations up and down along a column. While this is limited to certain chemicals during different stages in the separation process, it enables us to selectively pick up those target molecules.

They provide a number of benefits that make them highly valuable, including being presumably cheap to implement on an industrial scale. Their main advantage is amazing chemical separation efficiency. This efficiency is very critical to create a wide range of products fast and efficiently. Moreover, they can operate high-scale by manufacturing bulk of product altogether. It saves valuable time and money for businesses. This YHCHEM Stainless Steel Distillation Column is also the much safer alternative to manually separating chemicals and using industrial distillation columns. This technology system also minimizes the risks of accidents and reduces exposure to hazardous chemicals.

The chemical industry employs industrial distillation columns in a host of areas One of the most relevant cases is its use as a fuel that can be converted into gasoline or diesel, with an important role in transportation. Aside from this, use of these columns also extends to production essentials like ammonia and ethylene etc. Furthermore, industrial distillation columns also plays a role in the production of pharmaceuticals that keep us healthy as well as plastics—plastic items even you used today.

There are in fact new ideas and advancements made all the time when it comes to industrial distillation columns. Just one of the never-ending quests scientists and engineers are always exploring is how to improve materials that in turn can be forced into service at high or cold temperatures, near cavitation pressures and among some very agro chemicals. Graphene and other new materials could greatly increase the strength and lifespan of columns. In addition, technology in the form of better software has emerged to enable more effective control over columns. This tool would further eliminate the need for you to through extensive data, making the segregation process more accurate and efficient leading up better results.

As a company has been listed successfully have a stable financial support Industrial distillation column development capability. We will adhere the market-driven philosophy and continue push product innovation to create worth for our customers and employees.

We are a world pioneer technological innovation, R and D and technology upgrades. We continuously introduce international advanced technologies while continuously conducting independent innovations technological improvements. We have established joint labs in conjunction with research institutes like Shanghai Chemical Industry Industrial distillation column Institute and East China University Science and Technology. These laboratories are committed providing customers most competitive solutions and products.

Our products have assisted thousands well-known businesses more than 100 countries well as regions throughout Industrial distillation column, gaining the trust of many recognitions. We're committed to improving our products and services according to the feedback of our customers.

We Industrial distillation column range of products that include glassware well as temperature control, reactions and distillation equipment. Our product line made to meet the demands of various industries. With number of services stations, We offer our customers scientific single-stop services and products that provide prompt technical support after-sales throughout the entire usage process.