Rectification columns like the diaphragm pump are essential in distillation. These columns aid in separating one chemical from another in a liquid mixture by boiling and cooling them at varying temperatures. When you start to learn how rectification columns work, you can know why they matter in numerous industries. When a solution of liquids is heated, those with the lowest boiling points convert to gas first. The gases move up the rectification column and contact cooler surfaces. The lower temperature surfaces cause the gases to turn back into liquid. This helps to separate the components of the mixture according to their boiling points.

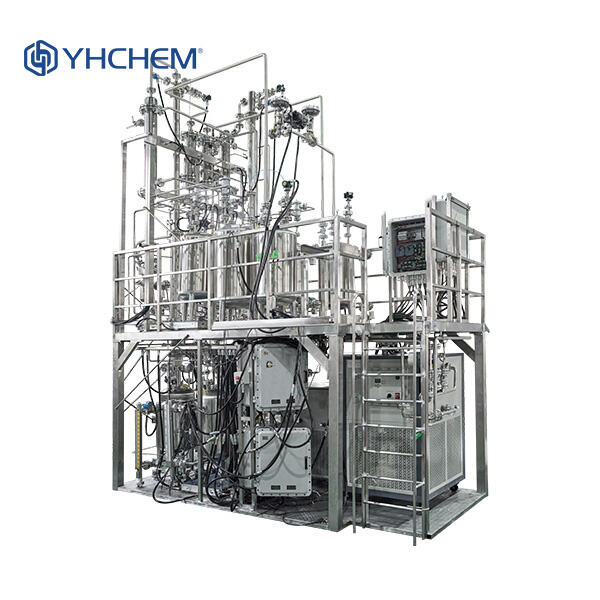

The rectification columns as well as the gear pump: designing of them is very important so that work them well. A good design ensures the column can divide the components of a mixture efficiently. How tall the column is, how wide it is and how many trays there are inside all influence how well the column works. And the qualified rectification column is able to output better finished products.

Rectification columns and reactor both purify chemicals. Removing the impurities and undesirable compounds is achieved by separating the components of a mixed solution according to boiling points. This is especially true in industries such as pharmaceuticals or food production where purity is of crucial concern. Through rectification columns, businesses can ensure that their products adhere to the very strict quality standards.

Here’s a plain language guide to the working of rectifying columns and a distillation column. The blend to be distilled is warmed and vaporized in a boiler on the bottom of the column. The gases rise passing through a series of trays that help to separate them according to their boiling points. At the top of the column the hot gases encounter the cooler surfaces and return to liquid form. The purified components are then recovered from the column bottom.

There are a number of reasons why businesses use rectification columns and homogenizer. These columns allow industries to isolate different parts of a mixture efficiently, resulting in a higher quality final product. It can also save money because companies can make higher quality products with less impurities. Rectification columns also enable companies to meet regulations governing product purity and quality.

As a listed company is successful, have stable Rectification columns sustainable growth capacity. We follow market-driven principles drive continuous product innovation to create benefits for our customers and employees.

We provide variety of products that include glassware including temperature control, reactions distillation Rectification columns. Our product range is specifically designed meet the needs of different industries. With multiple service supply stations offer customers scientists all-in-one products services, ensuring timely technical support and after-sales support all the way through their journey.

We are a leader in technological innovations R and D capability globally, continuously innovating international advanced technologies conducting continuous independent technological innovation upgrades. have developed joint labs in collaboration with research institutions such as the Shanghai Chemical Industry Research Institute well as the East China University of Science and Rectification columns. These labs will provide customers the most competitive products and solutions.

We've supplied products thousands of reputable companies over 100 Rectification columns we have gained a wide amount of appreciation trust. We're committed improving our products and services according to the feedback our customers.