Everything About Batch Distillation Units

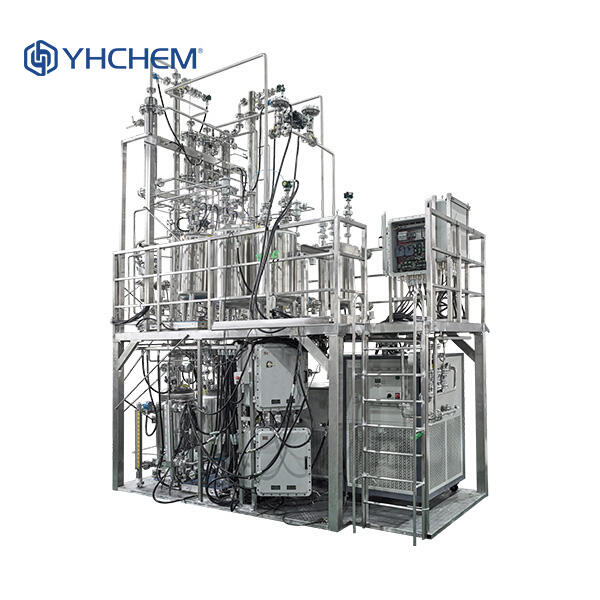

Ever pondered over what really goes on within your favorite beverages, whether alcohol or juice? So, a key equipment that is essential to this process of manufacturing - Batch Distillation Unit. This contrivance has been particularly designed to heat a mixture and separate/extract valuables from the same by causing them to vaporize, then cooling down these vapors in order that they convert back into liquids. In this blog, we are going to take a closer look at everything you need to know about YHCHEM Stainless Steel Molecular Distillation; the reasons why it is used today and its safety innovations that can shape other industries.

Benefits of Batch Distillation Unit

There are a number of reasons why you should use batch distillation units over other types of the equipment. For one, they offer great versatility and flexibility that make them ideal for use in industries like pharmaceuticals, chemicals or food processing. They are also budget-friendly machines, requiring minimal energy to consume and cost next-to-nothing in upkeep. Additionally, these models are especially efficient and tend to very consistently produce broad-level results which has made them popular in the world of manufacturing.

Over time, batch distillation has been the subject of many technical improvements in manufacture. An important innovation is the automation of distillation, which allows for more precise output characteristics and fewer human inconsistencies. One of the key innovation are computer software that manage and control the distillation. This YHCHEM batch column distillation improves control over the entire process, translating to a more uniform end-product quality.

These batch distillation units are very well designed with many safety precautions to prevent harming the operator and their environment. The units are built using high-temperature and corrosive-resistant materials. Furthermore, they come equipped with sensors to uncover any unsafe conditions and shut down the system immediately in order to avoid accidents. It is also necessary to receive the correct training and follow safety protocols, in order for these units to operate safely and efficiently.

Batch distillation is an important step in separating raw materials into components with a certain degree of purity. It can separate a variety of complex components from various sources such as crude oil, botanical extracts and even water. YHCHEM batch distillation unit is of particular value in the extraction of essential oils, flavorings and fragrances. What is more, they are used worldwide to create alcoholic drinks such as whiskey and gin.

In order to run the batch distillation unit1, mixture is introduced into a distillation flask. Then the flask is attached to a condenser, with which it cools by cooling water or air. The flask is then heated to make an evaporation so boiling of the mixture occurs which leads in vapors. The vapor rises and condenses in the Condenser, where it can be collected either pure liquid phase. The residue left over after distillation is poured out of the flask and also washed, but cleaned so that it can once more be used.

We have solid financial position and Batch distillation unit capacity development as publicly traded company. We will adhere to principles the market and will continue to drive innovation our products to provide benefits for our customers and employees.

We offer a wide range products, including Batch distillation unit, temperature control, distillation reaction instruments. Our product range is made to meet the demands different industries. We provide our customers an all-in-one service that includes multiple service supply centers, providing customers prompt technical support well as after-sales support products.

We are a world pioneer technological innovation, R and D and technology upgrades. We continuously introduce international advanced technologies while continuously conducting independent innovations technological improvements. We have established joint labs in conjunction with research institutes like Shanghai Chemical Industry Batch distillation unit Institute and East China University Science and Technology. These laboratories are committed providing customers most competitive solutions and products.

We've supplied products to myriads of well-known businesses over 100 countries, earning wide Batch distillation unit trust. We're committed to improving services and products based on customer feedback.

A Large part of the quality issue with batch distillation units is due to the manufacturer. You should choose a well-known manufacturer with an established history of producing reliable, quality equipment. Once an individual buys some batch distillation equipment, the customer can learn more service options and post-purchase maintenance. Regularly maintaining this unit is important to maintain the best performance of it and to make sure that it can work for a long time.

Batch Distillation Units on the other hand are meant for following applications

Batch distillation units have a wide range of applications. They are one of the essential tools for aromatics, flavors & fragrance production in various industries. YHCHEM distillation unit are also a key tool in the pharmaceutical industry to pull out of essential oils and purify medicines. For example, batch distillation is the primary separation process in alcohol production where it is used to make spirits of differing alcohol concentration.